Ridge Tool Company

5

Power Drive Inspection

WARNING

To prevent serious injury, inspect your Power Drive.

The following inspection procedures should be per-

formed on a daily basis:

1. Make sure Power Drive is unplugged.

2. Inspect the power cord and plug for damage. If the

plug has been modified, is missing the grounding

pin, or if the cord is damaged, do not use the Power

Drive until the cord has been replaced.

3. Inspect the Power Drive for any broken, missing,

misaligned or binding parts as well as any other con-

ditions which may affect the safe and normal opera-

tion of the tool. If any of these conditions are present,

do not use the Power Drive until the condition has

been repaired.

4. Lubricate the Power Drive if necessary according to

the Maintenance Instructions.

5. Use tools and accessories that are designed for your

Power Drive and meet the needs of your application.

The correct tools and accessories allow you to do the

job successfully and safely. Accessories suitable for

use with other equipment may be hazardous when

used with this Power Drive.

6. Clean any oil, grease or dirt from all equipment han-

dles and controls. This reduces the risk of injury due

to a tool or control slipping from your grip.

7. Inspect the cutting edges of your dies. If necessary,

have them replaced prior to using the Power Drive.

Dull or damaged dies can lead to poor quality threads.

8. Clean metal shavings and other debris from the chip

tray of the 418 Oiler. Check the level and quality of the

thread cutting oil. Replace or add oil if necessary.

NOTE! Thread cutting oil lubricates and cools the threads

during the threading operation. A dirty or poor

grade cutting oil can result in poor thread quality

and increased threading torque.

Tool and Work Area Set-Up

WARNING

To prevent serious injury, proper set-up of the

Power Drive and work area is required. The fol-

lowing procedures should be followed to ensure

proper set-up of the tool.

1. Locate a work area that has the following:

• Adequate lighting

• No flammable liquids, vapors or dust that may

ignite.

• Grounded electrical outlet

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for operator. Do not use the Power Drive

while standing in water.

• Level ground for tristand vise and pipe stands.

2. Clean up the work area prior to setting up any equip-

ment. Always wipe up any oil that may have splashed

or dripped from the oiler to prevent slips and falls.

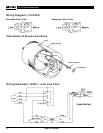

3. Plug the Power Drive into the electrical outlet making

sure to position the power cord along the clear path

selected earlier. If the power cord does not reach the

outlet, use an extension cord in good condition.

To avoid electrical shock and electrical

fires, never use an extension cord that is damaged or

does not meet the following requirements:

• The cord has a three-prong plug similar to shown

in Electrical Safety section.

• The cord is rated as “W” or “W-A” if being used

outdoors.

• The cord has sufficient wire thickness (14 AWG

below 25′/12 AWG 25′ - 50′). If the wire thickness

is too small, the cord may overheat, melting the

cord’s insulation or causing nearby objects to

ignite.

To reduce risk of electrical shock, keep all

electrical connections dry and off the ground. Do not

touch plug with wet hands.

4. Check the Power Drive to insure it is operating prop-

erly.

• Depress the switch and make sure it controls the

stopping of the Power Drive by releasing the switch.

No. 700 Portable Power Drive

WARNING

WARNING