18

19

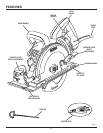

Fig. 14

OPERATION

CROSS CUTTING

See Figure 14.

When making a cross cut, align the line of cut with the full

length kerf indicator on the base as shown in figure 14.

Since blade thicknesses vary, always make a trial cut in scrap

material along a guideline to determine how much, if any, you

must offset the guideline to produce an accurate cut.

NOTE: The distance from the line of cut to the guideline is

the amount you should offset the guide.

BEVEL CUTTING

The base of the saw may be adjusted for bevel cuts up to

51.5°.

WARNING:

The tool should never be connected to a power

supply when you are assembling parts, making

adjustments, cleaning, performing maintenance,

or when the tool is not in use. Disconnecting the

tool will prevent accidental starting that could cause

serious injury.

POSITIVE 0° BEVEL STOP

The saw has a positive 0° bevel stop that has been factory

adjusted to assure 0° angle of the saw blade when making

90° cuts.

TO CHECK POSITIVE 0° BEVEL STOP

See Figure 15.

n Unplug the saw.

n Place the saw in an upside down position on a work-

bench.

n Move the lower blade guard out of the way so that the

saw blade is exposed.

n Check the squareness of the saw blade to the base of

the saw using a carpenter’s square.

LINE OF

CUT

FULL LENGTH

KERF

INDICATOR

Fig. 15

BLADE

COMBINATION

SQUARE