19

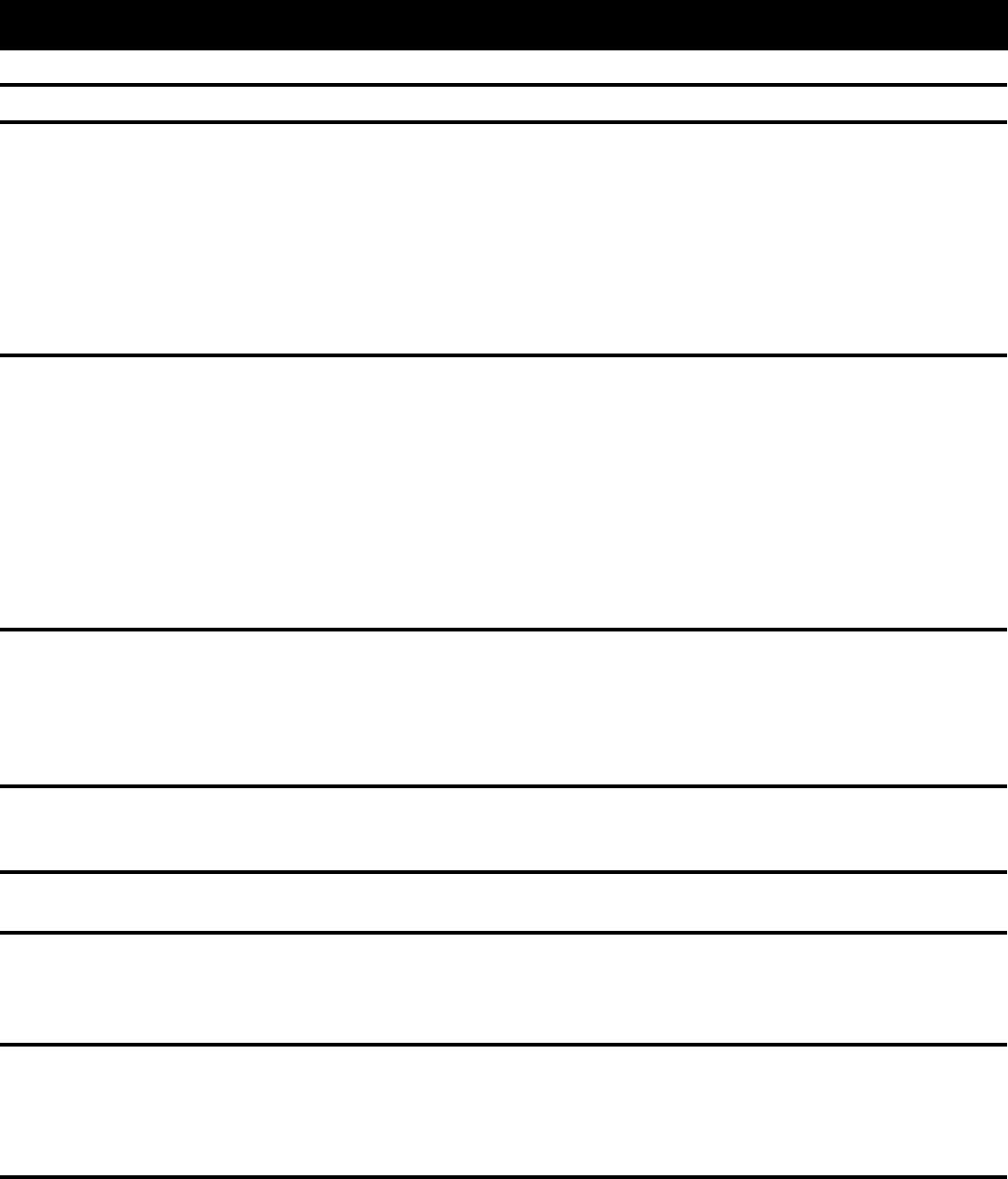

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Machine does not start 1. Power cord not plugged in. 1. Plug in cord.

2. Power cord is damaged. 2. Have the cord replaced at your

nearest authorized service center.

3. Circuit breaker is tripped. 3. Reset circuit breaker.

4. Circuit fuse is blown 4. Replace circuit fuse.

5. Switch is damaged or burned out. 5. Have the switch replaced at your

nearest authorized service center

and request a voltage check from

the power company.

Motor does not reach full speed or 1. Voltage from power source is low. 1. Request a voltage check from the

power. power company.

2. Circuit is overloaded. 2. Test on a different circuit or without

anything else on circuit.

3. Motor burned out. 3. Have tool serviced; request voltage

check from the power company.

4. Fuses or circuit breakers are 4. Have an electrician replace with a

wrong size. 15 amp fuse or circuit breaker.

5. Extension cord is too long. 5. Use a shorter extension cord.

6. Switch is defective. 6. Have the switch replaced at your

nearest authorized service center.

Motor stalls, blows fuses, or trips 1. Switch is defective. 1. Have the switch replaced at your

circuit breakers. nearest authorized service center.

2. Voltage from source is low. 2. Request a voltage check from the

power company.

3. Fuses or circuit breakers are 3. Have an electrician replace with a

wrong size or defective. 15 amp fuse or circuit breaker.

Motor overheats. 1. Motor is overloaded. 1. Request a voltage check from the

power company.

2. Wheel is being fed into work too fast. 2. Feed wheel into work slower.

Machine is noisy when running. 1. Motor needs attention. 1. Have the motor checked at your

nearest authorized service center.

Wheel hits table. 1. Wheel not properly installed. 1. See “Removal and Installation of

Wheel” section.

2. Depth stop setting incorrect. 2. Adjust the depth stop. See “Depth

Stop” section.

Wheel does not cut through 1. Depth stop setting incorrect. 1. Adjust the depth stop. See “Depth

workpiece. Stop” section.

2. Wheel worn too much. 2. Replace with a new 14 in. abrasive

cut off wheel.

3. Incorrect cutting operation. 3. See “Cut-Off” section.

Machine vibrates or shakes 1. Wheel is out-of-round. 1. Replace wheel.

excessively. 2. Wheel is chipped 2. Replace wheel.

3. Wheel is loose. 3. Tighten wheel bolt on arbor.

4. Machine is not secure. 4. Check and tighten all hardware.

5. Work surface is uneven. 5. Relocate and secure on a flat

surface.