10

20

5

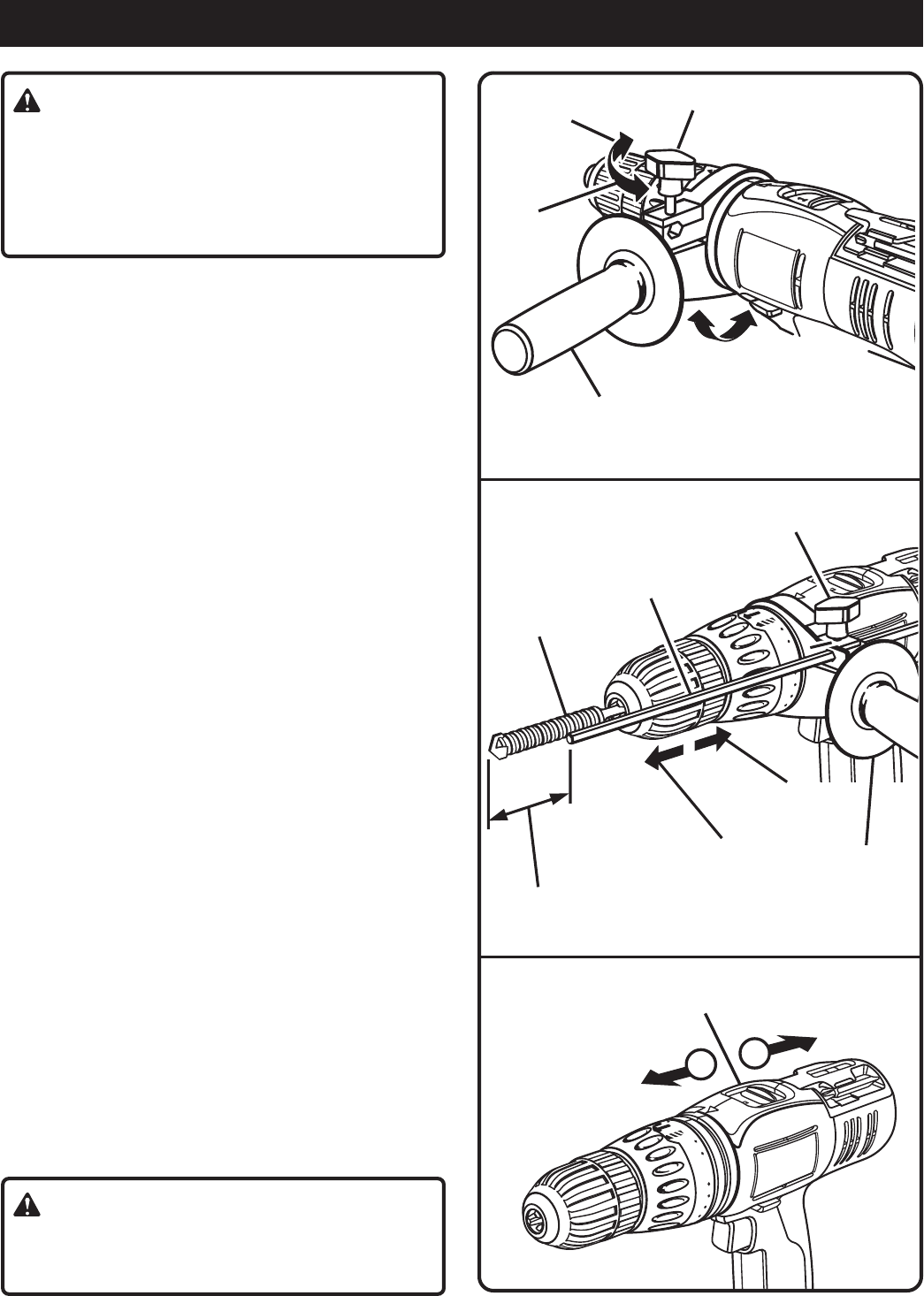

ADJUSTMENTS

WARNING:

The hammer drill should never be connected to a

power supply when you are assembling parts, making

adjustments, cleaning, performing maintenance, or

when the tool is not in use. Disconnecting the tool will

prevent accidental starting that could cause serious

injury.

ADJUSTING THE AUXILIARY HANDLE

ASSEMBLY

See Figure 2.

Follow these steps to adjust the auxiliary handle assembly.

■ Loosen the auxiliary handle assembly by turning the

knob counterclockwise.

■ Rotate the auxiliary handle assembly to the desired

location.

■ Tighten the auxiliary handle assembly securely by

turning the knob clockwise.

ADJUSTING THE DEPTH GAUGE ROD

See Figure 3.

Follow these steps to adjust the depth gauge rod.

■ Lock the trigger switch by placing the rotation

selector in the center position.

■ Loosen the auxiliary handle assembly by turning the

knob counterclockwise.

■ Adjust the depth gauge rod so that the drill bit

extends beyond the end of the rod to the required

drilling depth.

■ Tighten the auxiliary handle assembly by turning the

knob clockwise.

ADJUSTING THE SPEED

See Figure 4.

The hammer drill has a two-speed gear train that provides

a high speed of approximately 1,400/min and a low speed

of approximately 400/min (stated speeds are with the

trigger switch in the “Full-on” position).

Follow these steps to adjust the speed.

■

For high speed

: Slide the two-speed gear train switch

to “2.”

■

For low speed

: Slide the two-speed gear train switch

to “1.”

Note: If you have difficulty changing from one gear

range to the other, turn the chuck by hand until the

gears engage.

CAUTION:

Never change gears while the tool is running. Failure

to obey this caution could result in serious damage to

the drill.

Fig. 2

20

5

8

Fig. 3

Fig. 4

TO

TIGHTEN

DRILLING

DEPTH

KNOB

DRILL BIT

TO DECREASE

DRILLING DEPTH

AUXILIARY

HANDLE

ASSEMBLY

TO INCREASE

DRILLING DEPTH

AUXILIARY

HANDLE

ASSEMBLY

KNOB

TO

LOOSEN

HI

SPEED

TWO-SPEED

GEAR TRAIN (HI-LO)

1

2

LO

SPEED

DEPTH GAUGE

ROD

20