assembly

TO AVOID BEING SCRAPED SHOULD BLADE

SUDDENLY UNCOIL WEAR SAFETY GOGGLES AND

CAREFULLY UNCOIL THE BLADE HOLDING iT AT

ARMS LENGTH.

7. Carefully uncoil the blade, holding it at arms length.

8. Place the blade over the wheels with the teeth pointing

downwards toward the table as shown. Make sure the

blade is between the blade guides and is in the center of

the rubber tl res.

NOTE: Your bandsaw can be used with blades of

various widths from 1/8" to 1/2". The saw must be

adjusted to the proper blade tension setting for the

blade to be used. A 1/4" wide blade is included with

this saw.

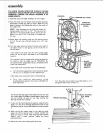

9. Screw down the tension knob until the pointer points

to 1/4. This will pu_ sufficient tension on a 1/4" wide

blade.

10. Turr the upper wheel by hand a few times and notice if

the blade remains in the approx, center of the tire on

the top wheel.

If the blade moves away from the center of the wheel

while you are turning it, the blade is not TRACKING

properw.

The top wheel shaft is hinged which allows the wheel to

be tilted so that the blade can be TRACKED, By

turning the tracking adjustment screw, the wheel will De

tilted. (see illustration).

If the blade moves toward the front of the band saw:

a. Turn the tracking adjustment screw clockwise about

1/4 of a turn, as though you were tightening it.

If the blade moves toward the back of the band saw:

a. Turn the tracking adjustment screw

counterclockwise about 1/4 of a turn as though you

were loosening it.

POINTER

_--TENSION ADJ. KNOB

]

T

SCREW

BLADE

CENTERED

ON TIRES

OF BOTH

WHEELS

Turn the screw just enough to cause the blade to run in

the appro×=mate center of the tire.

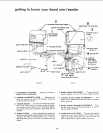

The thrust bearings support the blade from the rear and

will rotate when the blade is pushed against them while

you are cutting. As soon as you stop cutting, the

bearings should stop rotating,

11

To be sure the thrust bearing is properly supporting the

blade, turn the thrust bearing adjustment knob so that

the bearing moves toward the blade and almost touches

it.

12. While turning the upper wheel to the right by hand,

adjust the thrust bearing until it barely touches the

blade and starts to rotate. Now move the bearing back

slightly, until it stops rotating. Tighten the thrust

bearing setscrew.

13. Adjust the lower thrust bearing the same way.

THRUST BEARING

/

THRUST BEARING

ADJ. KNOB

14