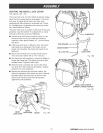

iNSTALLiNG THE FRONT TABLE

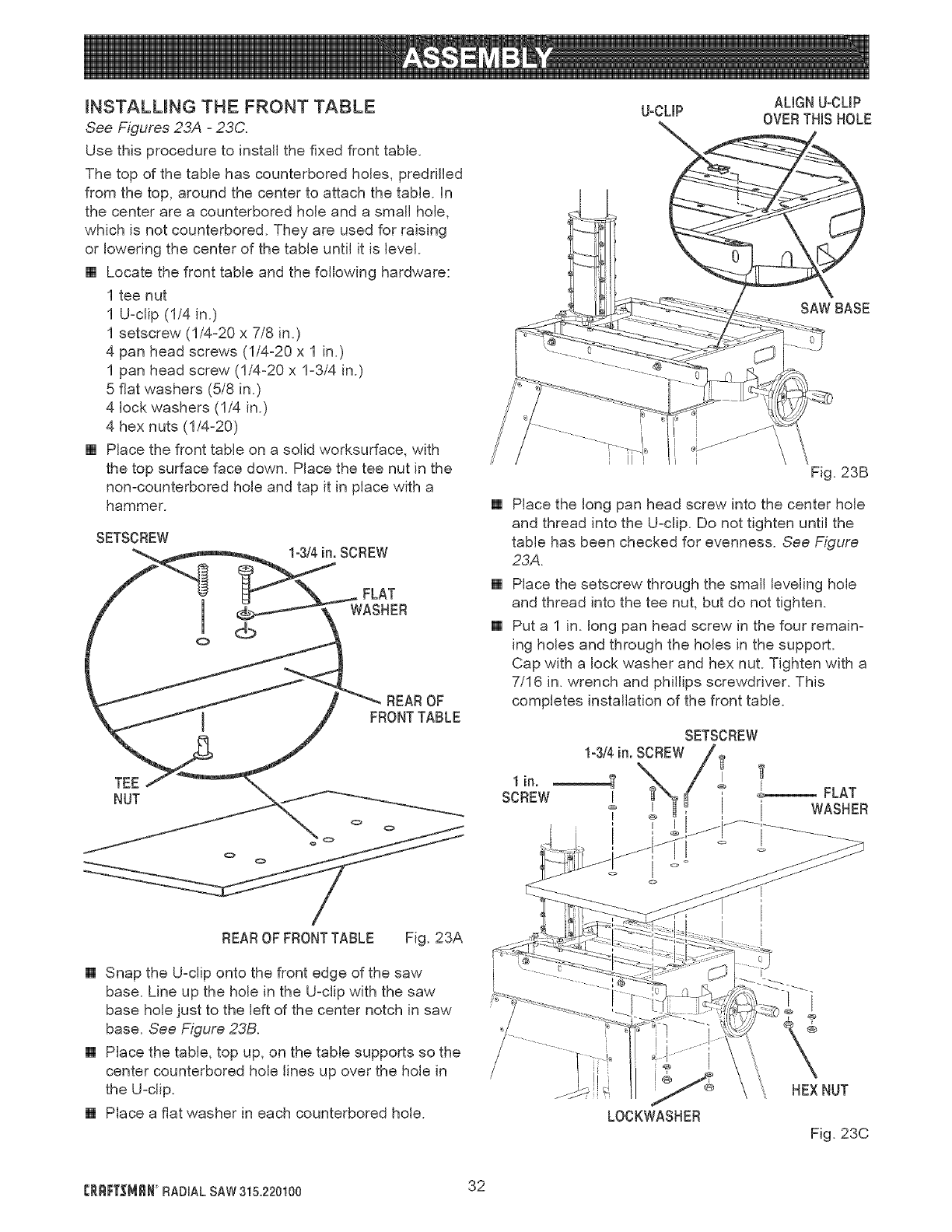

See Figures 23A - 23C.

Use this procedure to install the fixed front table.

The top of the table has counterbored holes, predrifled

from the top, around the center to attach the table, in

the center are a counterbored hole and a small hole,

which is not counterbored. They are used for raising

or lowering the center of the table until it is level.

[] Locate the front table and the following hardware:

1 tee nut

1 U-clip (1/4 in.)

1 setscrew (1/4-20 x 7/8 in.)

4 pan head screws (1/4-20 x 1 in.)

1 pan head screw (1/4-20 x 1-3/4 in.)

5 flat washers (5/8 in.)

4 lock washers (1/4 in.)

4 hex nuts (1/4-20)

[] Place the front table on a solid worksurface, with

the top surface face down. Place the tee nut in the

non-counterbored hole and tap it in place with a

hammer.

SETSCREW

_ SCREW

_ / _'_ REAROF

REAROF FRONTTABLE Fig. 23A

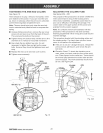

[] Snap the U-clip onto the front edge of the saw

base. Line up the hole in the U-cfip with the saw

base hole just to the left of the center notch in saw

base. See Figure 23B.

[] Place the table, top up, on the table supports so the

center counterbored hole lines up over the hole in

the U-clip.

[] Place a fiat washer in each counterbored hole.

ALIGNU-CLIP

U-CLIP OVERTHiSHOLE

SAW BASE

Fig. 23B

[] Place the long pan head screw into the center hole

and thread into the U-clip. Do not tighten until the

table has been checked for evenness. See Figure

23A.

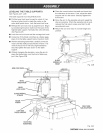

[] Place the setscrew through the small leveling hole

and thread into the tee nut, but do not tighten.

[] Put a 1 in. long pan head screw in the four remain-

ing holes and through the holes in the support.

Cap with a lock washer and hex nut. Tighten with a

7/16 in. wrench and phillips screwdriver. This

completes installation of the front table.

1 in.

SCREW

SETSCREW

1-3/4 in. SCREW

_ , !, FLAT

Z Z ! WASHER

LOCKWASNER

HEX NUT

Fig. 23C

CRRF[_NRN RADIALSAW 315.220100 32