-27-

M1102/M1103 16-Speed Drill Press

SERVICE

SERVICE

Symptom Possible Cause Possible Solution

Machine does not

start or a breaker

trips.

1. Plug or receptacle is at fault or wired incor

-

rectly.

2. Start capacitor is faulty.

3. Motor connection is wired incorrectly.

4. Power supply is faulty, or is switched

OFF.

5. Safety switch key is at fault.

6. ON/OFF switch is faulty.

7. Cable or wiring is open or has high resistance.

8. Motor is at fault.

1. Test power plug and receptacle for good contact

and correct wiring.

2. Replace capacitor.

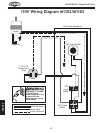

3. Correct motor wiring (see

Page 32).

4. Make sure all hot lines and grounds are operational

and have correct voltage on all legs.

5. Install or replace safety key, or replace switch

assembly.

6. Replace faulty switch.

7. Troubleshoot wires for internal or external breaks,

check for disconnected or corroded connections and

repair or replace wiring.

8. Test, repair or replace motor.

Machine stalls or

is underpowered.

1. Incorrect spindle speed for task.

2. Machine is undersized for the task.

3. Bit or cutter is dull.

4. Low power supply voltage.

5. Belt(s) is slipping.

6. Plug or receptacle is at fault.

7. Motor connection is wired incorrectly.

8. Pulley is slipping on shaft.

9. Motor bearings are at fault.

10. Motor has overheated.

11. Motor is at fault.

1. Decrease spindle speed.

2. Use smaller drill bits/cutters and reduce the feed

rate and spindle speed.

3. Sharpen/replace bit or cutter.

4. Make sure hot lines and grounds are operational w/

correct voltage.

5. Replace bad belts, align pulleys, and re-tension.

6. Test power plug and receptacle for good contact

and correct wiring.

7. Correct motor wiring (see

Page 32).

8. Replace loose pulley and shaft.

9. Rotate motor shaft for noisy or burnt bearings,

repair/replace as required.

10. Clean inside/outside of motor, let cool, and

reduce workload on machine.

11. Test, repair or replace motor.

Motor & Electrical

Troubleshooting

This section covers the most common problems and corrections with this type of

machine. WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop

!

Continued on next page