-20-

M1109 Combo Lathe/Mill

OPERATIONS

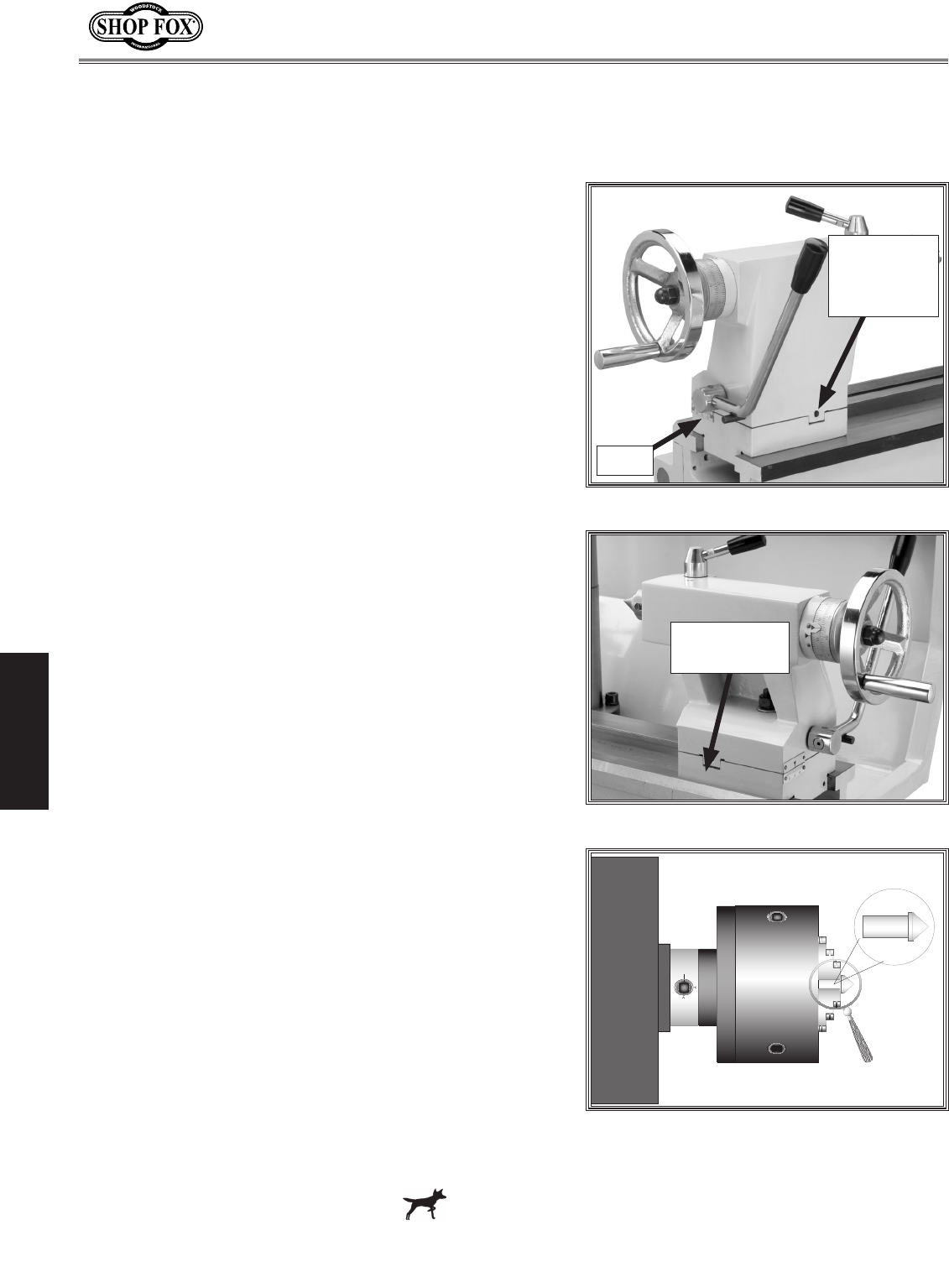

Cutting Shallow Tapers

with the Tailstock

To setup the tailstock to cut tapers, do these steps:

1. Lock the tailstock in position.

2. Alternately loosen and tighten the left and right

offset adjustment screws until the desired offset is

indicated on the scale

(see Figures 25 & 26).

3. Retighten the lock screw.

Note:

To return the tailstock back to the original

position, repeat the process until the centered posi

-

tion is indicated on the scale.

Figure 25. Right offset adjustment.

Right

Offset

Adjustment

Tailstock Alignment

The tailstock is aligned at the factory with the headstock.

We recommend that you take the time to ensure that the

tailstock is aligned to your own desired tolerances.

To align the tailstock, do these steps:

1. Using a precision level on the bedways, make sure

the lathe/mill is level side-to-side and front-to-back.

If the lathe/mill is not level, correct this condition

before proceeding.

2. Get two pieces of steel round stock, two inches in

diameter and six inches long.

3. Center drill both ends of one piece of the round

stock. Set it aside for use in

Step 6.

4. Using the other piece of stock, make a dead center

by turning a shoulder to make a shank. Flip the piece

over in the chuck and turn a 60º point (see

Figure

27).

Note:

As long as the dead center remains in the

chuck, the point of your center will remain true to

the spindle axis. Keep in mind that the point will

have to be refinished whenever it is removed and

returned to the chuck.

Figure 26. Left offset adjustment.

Figure 27. Tailstock centering dead

center.

Continued on next page

Scale

Left Offset

Adjustments