19

Blade Tension

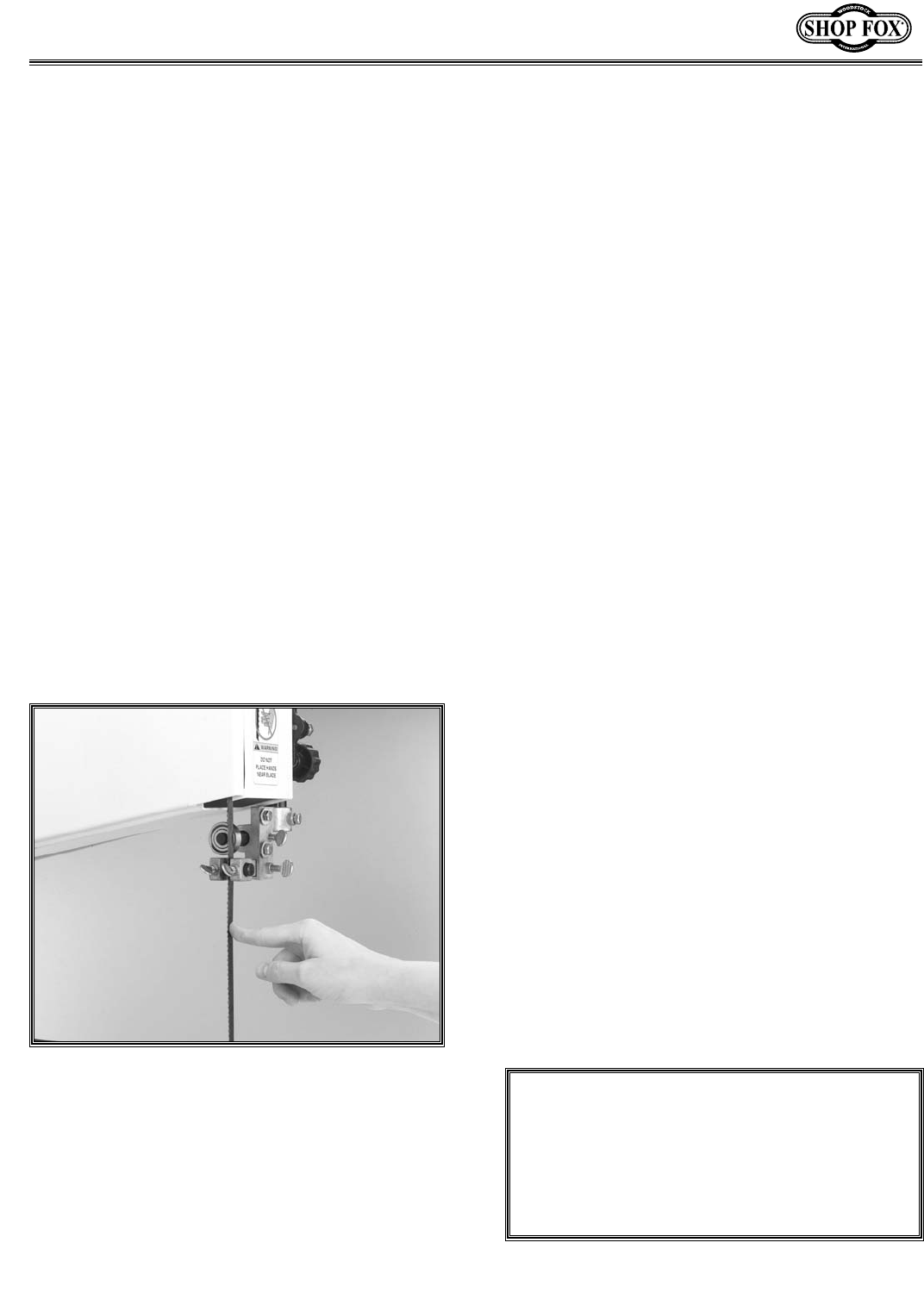

Figure 31. Checking blade deflection.

Blade tension is one of the most critical factors

in the performance of your bandsaw. The blade

must be tight enough so it does not sway during

a cut, yet stay flexible enough to bend around

the wheels.

Many factors determine the ideal tension for

every situation. For example, consider the width

and sharpness of blade being used, the thickness

and hardness of the material being cut and the

feed rate at which it is cut when determining

tension.

To adjust blade tension:

1. Make sure bandsaw is unplugged from the

power source.

2. With the tensioning handle in down position,

rotate clockwise to tighten the blade.

Rotate the handle counterclockwise to

loosen the blade.

Note: Because of the many factors involved,

there is no concrete rule for blade tension.

However, there are two common methods for

adjustment: Sound and Deflection.

To tighten your blade by sound:

1. With the blade on both upper and lower

wheels, tighten blade moderately. Remove

the blade guard and clear the guide blocks

away from the blade.

2. Progressively increase the tension, while

plucking the blade along the way.

3. You want to achieve a tightness that resem-

bles a musical tone when the blade is

plucked. If the sound starts decreasing in

volume, the blade is too tight. Aim for the

clearest musical tone possible.

4. Keep in mind that different blade widths

will produce higher or lower tones.

To tighten your blade by deflection:

1. Raise the blade guard.

2. Tighten the blade so that it deflects

approximately

1

⁄4" with moderate pressure

with your finger. See Figure 31.

3. Because “moderate pressure” may differ

with every individual, this method may not

be strictly reliable by measurement.

4. Similar to adjusting the blade by sound, this

method will require trial and error practice.

NOTICE

The tensioning handle provides extra lever-

age that makes it possible to over tighten

blade. Ensure you do not overtighten blade

or the blade will break.