-9-

W1681 Buffing Assembly

SETUP

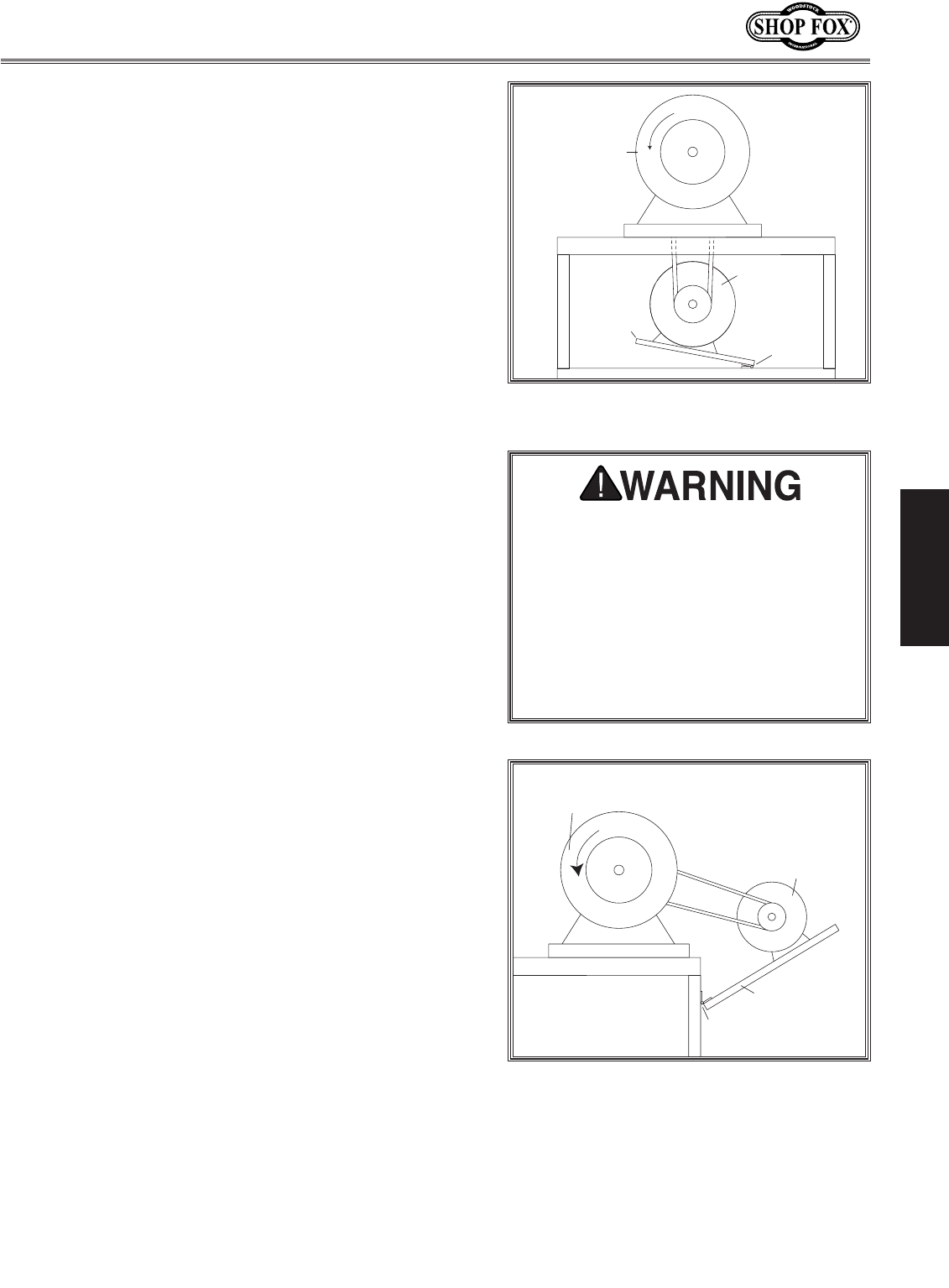

5. Mount the motor on a

1

⁄2" plywood platform below

the buffing assembly so that the motor pulley

is directly beneath the arbor pulley. Be sure to

orient the motor rotation so the buffing wheels

will be rotating downward on the working side of

the buffing assembly. Attach the platform to the

workbench using a piano hinge, as shown in Figure

5.

6. Install the V-belt on the desired pulleys.

Motor Behind

1. Position the buffing assembly on the workbench in

the desired position. Mark the four mounting hole

locations onto the workbench.

2. Remove the buffing assembly from the workbench

and set aside.

3. Using a drill, drill the mounting holes into the

workbench.

4. Place the buffing assembly over the mounting holes

in the workbench. Using (4)

5

⁄16" diameter lag bolts

or through bolts, attach the buffing assembly to the

workbench, making sure that it is secure.

5. Mount the motor on a

1

⁄2" plywood platform and

attach to the back of the workbench with a piano

hinge as shown in Figure 6. Be sure to orient the

motor rotation so the buffing wheels will be rotating

downward on the working side of the buffing

assembly. Attach the motor so the motor pulley is

in-line with the arbor pulley.

6. Install the V-belt on the desired pulleys.

7. We recommend building a plywood guard to cover

the V-belt and motor pulley assembly. This will

prevent the operator from accidentally coming into

contact with the belt during operation.

Buffer Assembly

Motor

Piano

Hinge

1/2" Plywood

Rotation

Working Side

Figure 5. Motor and buffer assembly

locations.

Buffer Assembly

Motor

1/2" Plywood

Piano Hinge

Rotation

Working Side

Figure 6. Side view of motor mounting

behind.

Be sure to mount the motor so the

rotation of the buffing wheels is down-

ward on the working side of the

assembly. If the buffing wheels rotate

upward on the working side, the

object being worked on could be pro-

pelled up and into the path of the

operator causing serious personal

injury.