-22-

W1713 Owner's Manual (Mfg. Since 6/03)

SERVICE

SERVICE

Troubleshooting

This section covers the most common problems and corrections with this type of machine. If you require

additional machine service not included in this section, please contact Woodstock International Technical

Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.biz. WARNING! DO NOT make any

adjustments until power is disconnected and moving parts have come to a complete stop!

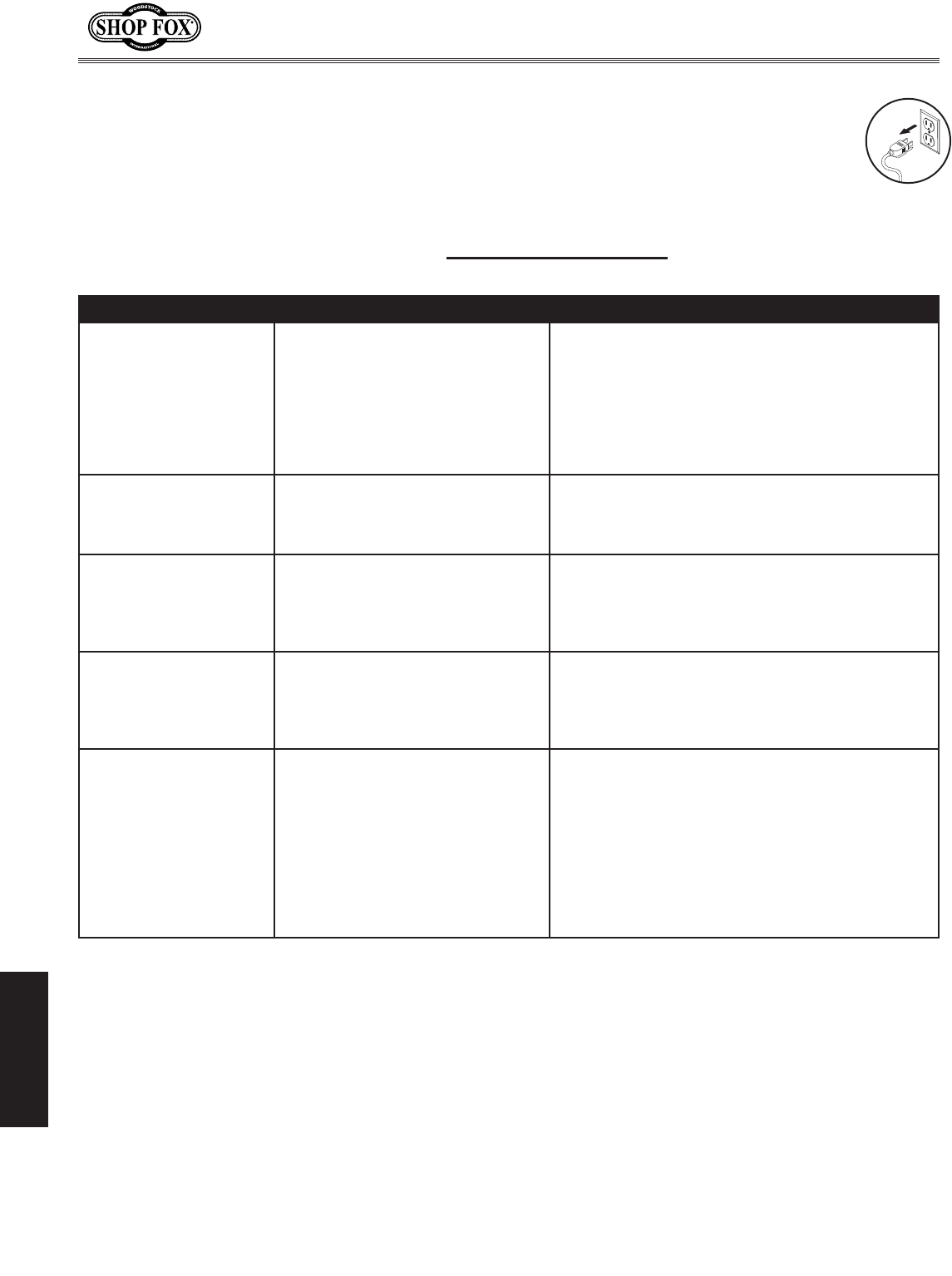

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Motor will not start;

circuit breaker trips.

1. Short circuit in line cord or plug;

circuit breaker at fault.

2. Variable speed/power switch at

fault.

3. Motor at fault.

4. Circuit board at fault

5. Low voltage.

1. Disconnect power, and inspect line cord and circuit

for electrical shorts and repair; replace circuit

breaker.

2. Test/replace variable speed/power switch.

3. Test/replace motor.

4. Test/replace circuit board.

5. Have the line voltage checked (110–120V required).

Motor slows or stalls

during operation.

1. Too much pressure applied to the

workpiece.

2 Low voltage.

3. Motor brushes worn or damaged.

1. Reduce the feed rate and pressure on the

workpiece.

2. Have the line voltage checked (110–120V required).

3. Inspect/replace motor brushes (refer to Page 21).

Excessive vibration from

saw.

1. Machine mounting fasteners loose.

2. Unsuitable mounting surface.

3. Loose motor mounts.

1. Inspect/re-tighten/replace.

2. The more solid the mounting surface is, the less

vibration will be felt (solid wood is better than

plywood).

3. Inspect/re-tighten/repair.

Blade will not stay on

layout line.

1. Blade not tensioned correctly.

2. Too much pressure applied to the

workpiece.

3. Blade holders not aligned

correctly.

1. Properly tension the blade (refer to Page 17).

2. Reduce the feed rate and pressure on the

workpiece.

3. Re-adjust the blade holders so that are aligned in a

straight line with the saw.

Excessive blade breakage. 1. Blade not tensioned correctly.

2. Not using relief cuts when cutting

tight curves; twisting blade.

3. Wrong blade for the operation.

4. Too much pressure on the blade.

5. Not enough blade teeth per inch.

1. Properly tension the blade (refer to Page 17).

2. Use more relief cuts for tight turns; reduce feed

rate; do not twist the blade—allow the blade to do

the work.

3. Refer to the Blade Selection Chart on Page 18 and

use the right blade for the operation.

4. Reduce the pressure on the workpiece as it passes

through the blade.

5. The blade should have at least 3 teeth in contact

with the workpiece at all times during operation.