-33-

W1808/W1809/W1810 Cyclone Dust Collectors

OPERATIONS

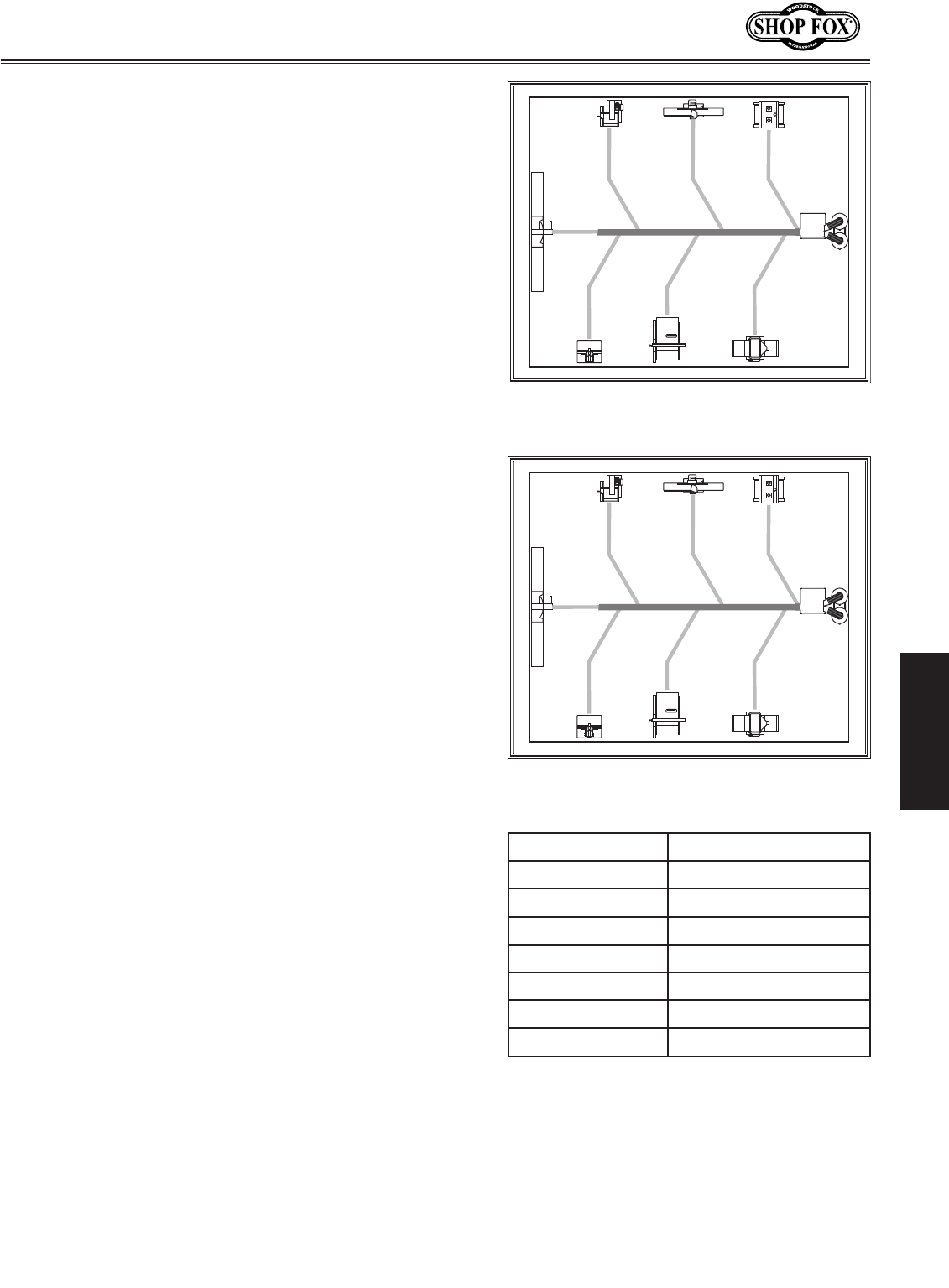

Determining Main Line Duct Size

The general rule of thumb for a main line duct is that the

velocity of the airflow must not fall below 3500 FPM.

For small/medium sized shops, using the inlet size of the

dust collector as the main line duct size will usually keep

the air velocity above 3500 FPM and, depending on your

system, will allow you to keep multiple branches open at

one time.

The inlet size is 7" for the W1808 and 8" for the W1809.

For the Model W1810, the intake is 8" with the reducer

installed. Mark your drawing as shown in Figure 49

.

Determining Branch Line Duct Size

The general rule of thumb for a branch line duct is that

the velocity of the airflow must not fall below 4000 FPM.

For small/medium sized shops, using the dust port size

from the machine as the branch line duct size will achieve

the correct velocity in most applications. However, if the

dust port on the machine is smaller than 4", make the

branch line 4" and reduce the line right before the dust

port.

Note: Systems with powerful dust collectors work better

if multiple blast gates are left open. This also allows you

to run two machines at once. Experiment with different

combinations of blast gates open/closed to find the best

results for your system.

Write your determined branch line sizes on your drawing,

as shown in Figure 50

.

Multiple Dust Ports

If your machine has multiple dust ports, add the total

CFM given for each dust port size from Figure 47

. Refer to

Figure 51 and find the CFM that is closest to your total to

determine the correct branch size. Split the branch line

just before the dust ports with matching duct sizes.

Two Machines on Same Branch Line

If both machines will be running at the same time, add

the total CFM given for each dust port size from Figure

47

.

If both the machines will never be run at the same time,

reference the machine with biggest dust port to Figure 51

and add blast gates after the Y-branch to open/close the

line to each machine.

Figure 49. Main line size labeled on

sketch.

Figure 50. Branch line sizes labeled on

sketch.

Total CFM Branch Line Size

600 5"

700 5"

800 6"

1000 6"

1200 7"

1400 8"

1600 8"

Figure 51. Branch line sizing chart by

total CFM (for use when multiple machines

share line).