-54-

For Machines Mfg. Since 8/09

SB1024/SB1025/SB1026

MAINTENANCE

Ram Ways

Oil Type ......Mobil Vactra 2 or ISO 68 Equivalent

Oil Amount ............................................. Thin Coat

Check/Add Frequency ............40 hrs. of Operation

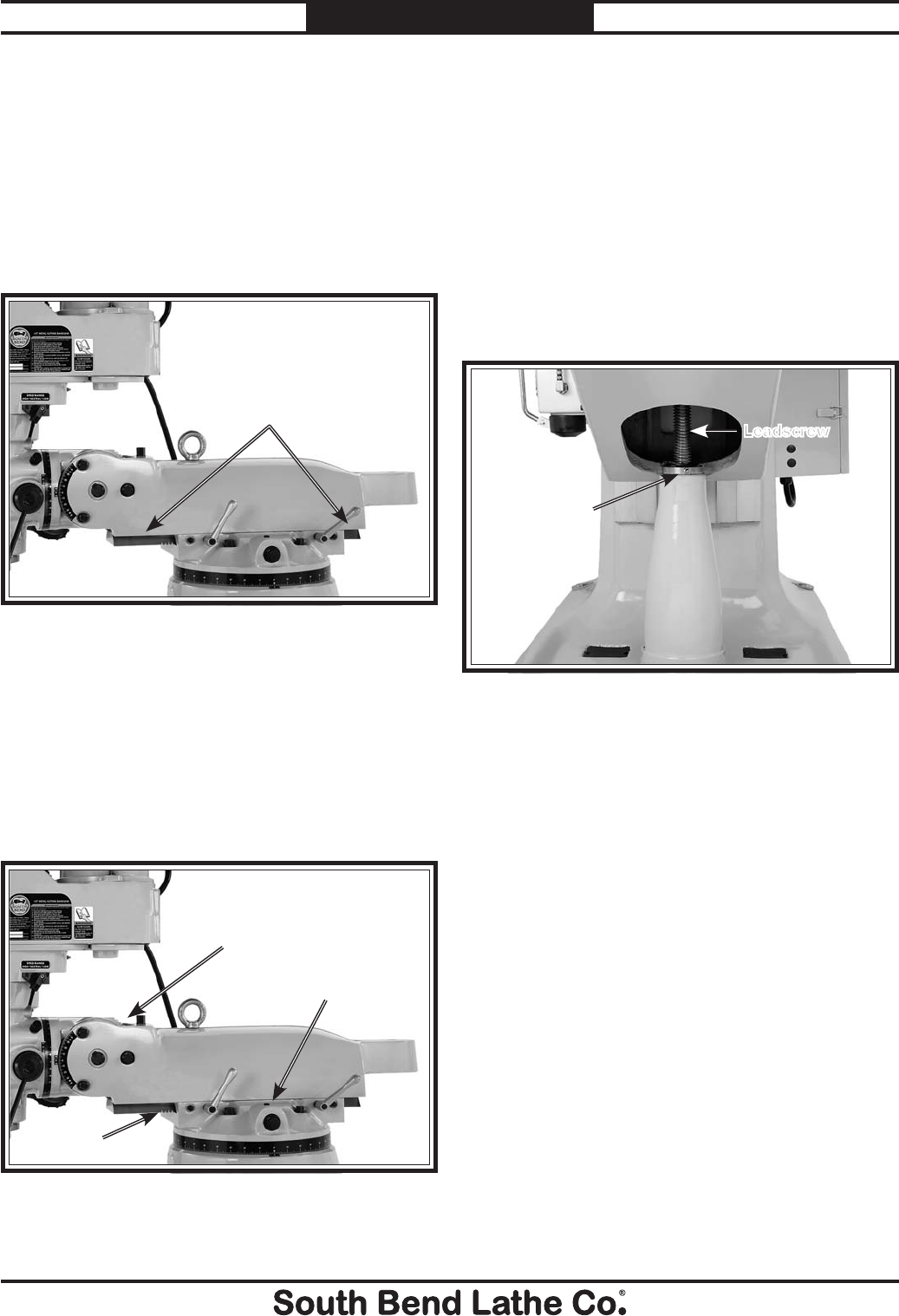

Move the ram back and forth as necessary

to access the full length of the ways (see

Figure 54), then use a clean shop rag to apply a

thin coat of lubricant.

Figure 54. Exposing the ram ways for lubrication.

Ram Ways

Table Elevation Leadscrew

Grease Type .........................NLGI 2 or Equivalent

Grease Amount ...................................... Thin Coat

Check/Add Frequency ............40 hrs. of Operation

Elevate the table all the way up, then use

mineral spirits to clean any debris and built-up

grime from the elevation leadscrew threads. Add

one pump from a grease gun to the leadscrew

grease fitting shown in Figure 56, then run

the knee up and down to distribute the grease.

Repeat this process until the entire leadscrew

Power Feed Gears

Grease Type .......Medium-Weight Lithium Grease

Grease Amount ...........Two Pumps of Grease Gun

Check/Add Frequency ............40 hrs. of Operation

Tool Needed Qty

Wrench 19mm .......................................................1

To lubricate the power feed gears:

1. DISCONNECT MACHINE FROM POWER!

Figure 56. Table elevation leadscrew and grease

fitting.

Grease

Fitting

Leadscrew

Head & Ram Rack & Pinion Gear

The interaction between the cast iron surfaces

of these devices (see Figure 55) produces a dry

powder that provides an adequate lubrication.

Do not apply any other lubricant which could

produce a stiff compound that may interfere with

smooth movement.

Figure 55. Locations of head and ram rack and pinion

gears.

Ram Rack

Ram Pinion

Gear

Head Rack

& Pinion Gear