For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026

-29-

OPERATION

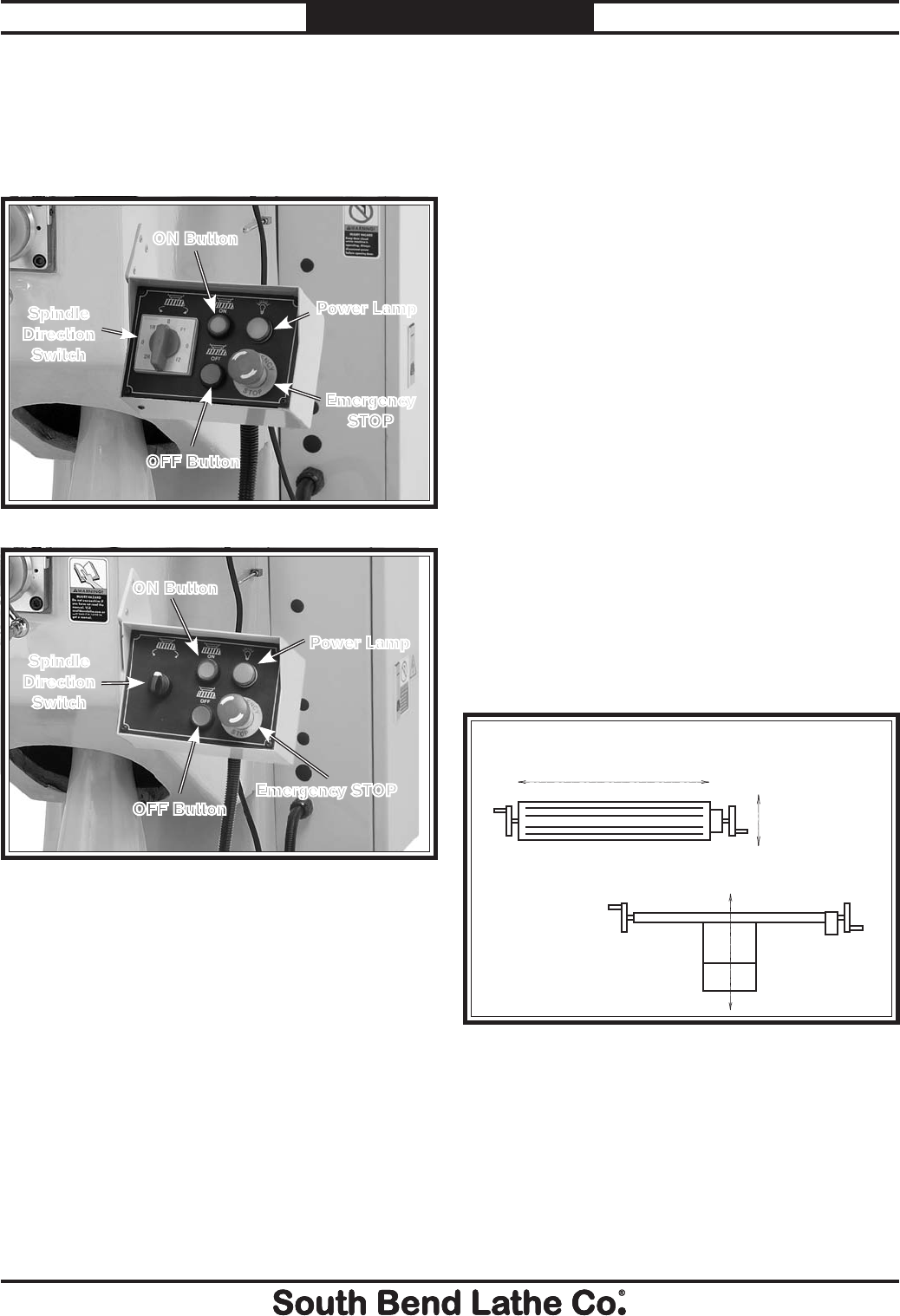

Control Panel

Use Figures 15–16 and the following

descriptions to understand the functions of the

mill control panel.

ON Button: Allows power flow to the motor. The

spindle direction switch must be used to start the

spindle rotation.

Power Lamp: Illuminates when the mill is

connected to a power source.

Emergency STOP Button: Stops the flow of power

to the motor. Twist clockwise until it pops out to

reset it, then press the ON button to re-establish

power flow to the motor.

OFF Button: Stops power flow to the motor.

Spindle Direction Switch: Starts, stops, and

reverses the direction of spindle rotation.

Note: The Model SB1025 has two positions for

each direction that electronically change the

speed of the motor and work in conjunction with

the belt housing controls to set the spindle speed

range (refer to "To set the spindle speed range

for the Model SB1025" on Page 39 for additional

details).

Table Movement

The mill table moves in three directions, as

illustrated in Figure 17:

s X-axis (longitudinal)

s 9AXISCROSS

s :AXISVERTICAL

These movements are controlled by table ball

HANDLESANDTHE:AXISCRANK!DDITIONALLYTHE

table can be moved along the X-axis with the

power feed.

Figure 17. The directions of table movement.

X-Axis or Longitudinal Travel

(Left & Right)

Y-Axis or

Cross Travel

(In & Out)

Z-Axis or Vertical Elevation

(Up & Down)

Figure 15. Model SB1025 control panel.

Spindle

Direction

Switch

Power Lamp

Emergency

STOP

ON Button

OFF Button

Figure 16. Model SB1024/SB1026 control panel.

Spindle

Direction

Switch

Power Lamp

ON Button

OFF Button

Emergency STOP