For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026

-59-

SERVICE

Adjusting Leadscrew

Backlash

Leadscrew backlash is the amount of motion

the leadscrew rotates before the attached device

begins to move.

Although the mill is equipped with double-

bronzed longitudinal and cross leadscrew nuts to

minimize backlash, leadscrews will always have

a certain amount of backlash that will increase

with normal wear.

Generally, 0.005"–0.010" leadscrew backlash

is acceptable to ensure smooth movement and

reduce the risk of premature thread wear.

However, if you find it necessary to adjust

leadscrew backlash, perform the procedures

listed below.

Tools Needed Qty

T-Handle Hex Wrench 5mm .................................1

Hex Wrench 3mm .................................................2

Hex Wrench 8mm .................................................1

Wrench 19mm .......................................................1

3. Rotate the adjustment plate on the

leadscrew nut in small increments, then

check the amount of backlash.

4. When you are satisfied with the adjustment,

re-tighten the two cap screws.

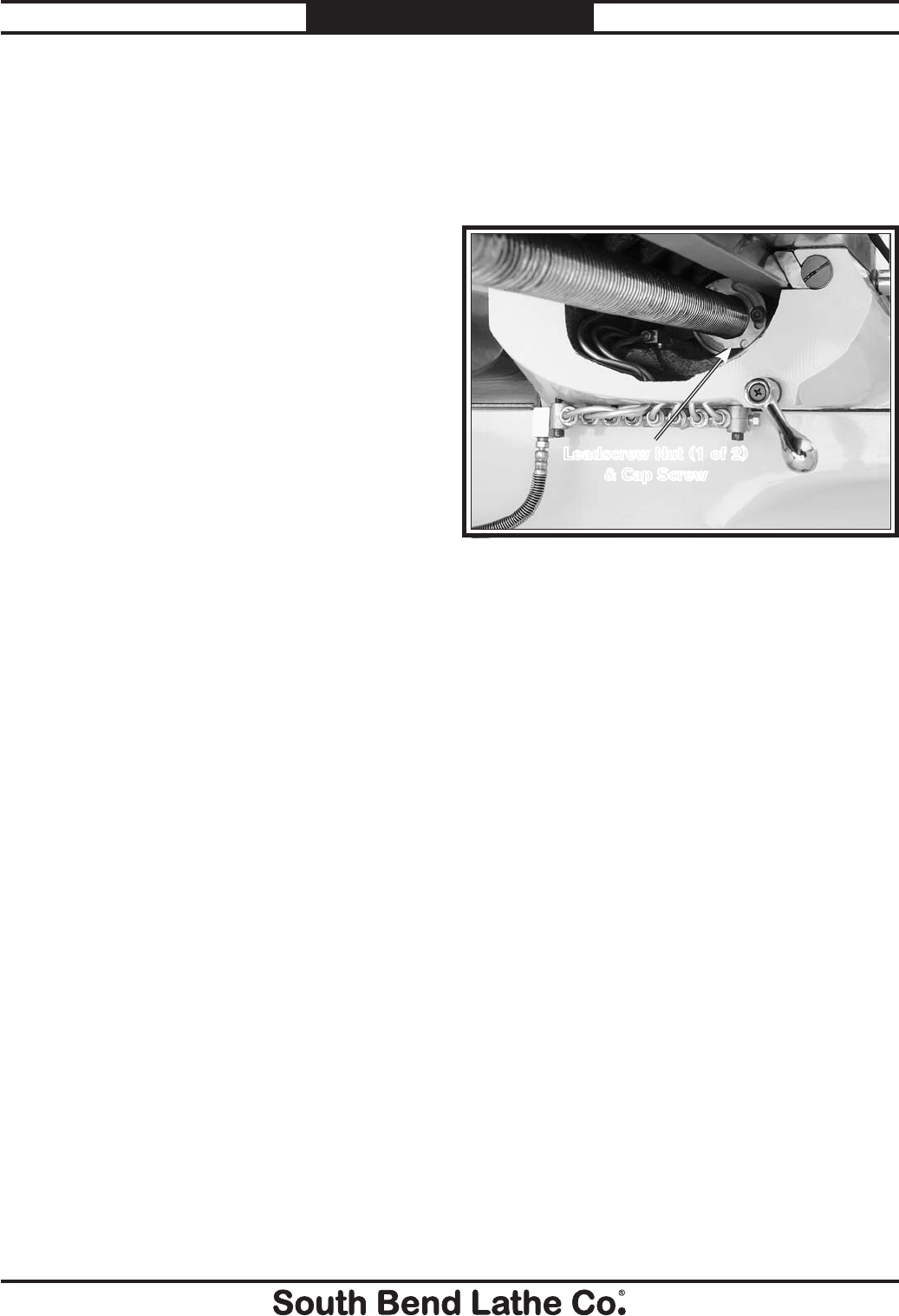

Longitudinal Leadscrew Backlash

1. DISCONNECT MILL FROM POWER!

2. Loosen the two cap screws on the leadscrew

nut accessed from underneath the left side of

the table, as shown in Figure 64.

Figure 64. Longitudinal leadscrew nut and cap screw,

as viewed from underneath the left side of the table.

Leadscrew Nut (1 of 2)

& Cap Screw