MB656 User Manual ◄ 15

TROUBLESHOOTING

This section describes how to nd and resolve problems

users may experience. If a situation occurs that is not

covered, call your Stanley Customer Service represen-

tative for assistance.

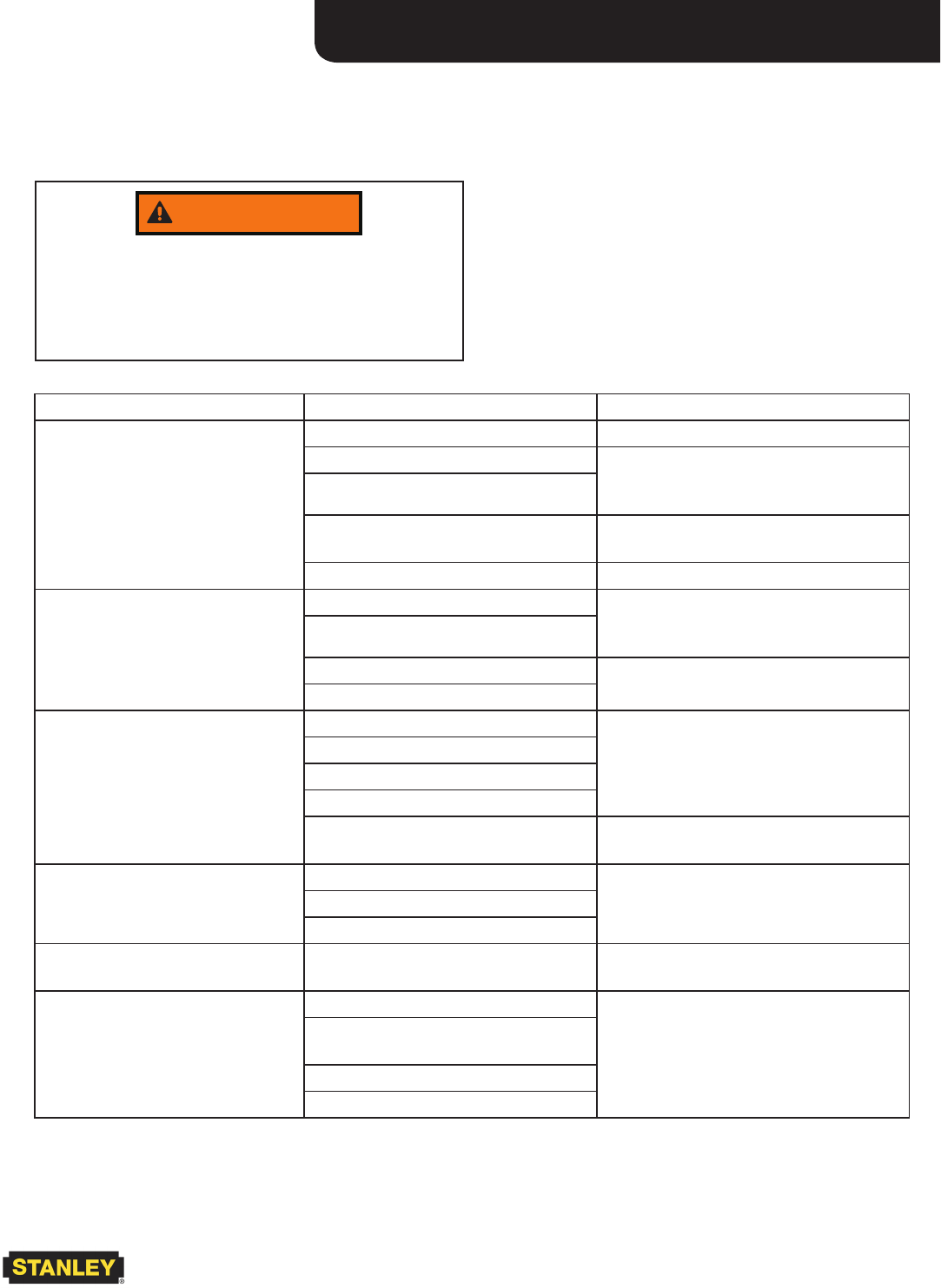

PROBLEM CAUSE SOLUTION

Breaker will not re. Low hydraulic oil level. Fill reservoir.

No ow to breaker. Have hydraulic circuit tested by

authorized dealer/distributor per

approved procedure.

Main relief set low.

Internal damage. Have unit serviced by an authorized

dealer/distributor.

Damaged quick couplers. Replace.

Breaker runs slowly. Low hydraulic ow Have hydraulic circuit tested by an

authorized dealer/distributor per

approved procedure.

Excessive heat build up.

Excessive nitrogen pressure. Have unit serviced by an authorized

dealer/distributor.

Internal leakage.

Breaker runs erratically. Low or excessive back-pressure. Have carrier serviced by an authorized

dealer/distributor.

Damaged switch or connection.

Relief set too low.

Internal damage.

Tool binding. Add grease to tool shank. Do not pry

while operating.

Breaker runs but at reduced

power.

Low accumulator charge. Have unit serviced by an authorized

dealer/distributor.

Excessive back-pressure.

Relief set too low.

Breaker leaks oil around tool bit

and tool bushing.

Lower seals failed. Have unit serviced by an authorized

dealer/distributor.

Hydraulic system overheats. Main relief set low. Have unit serviced by an authorized

dealer/distributor.

Insufcient cooling capability in

hydraulic circuit.

Line/hose size too small.

Excessive back-pressure.

If symptoms of poor performance develop, the following

chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the tool, always

check that the hydraulic power source is supplying the

correct hydraulic ow and pressure to the tool as listed

in the table below. Use a owmeter known to be accu-

rate. Check the ow with the hydraulic oil temperature at

least 80 °F/27 °C.

WARNING

Inspecting the tool or installing parts with the

hydraulic hoses connected can result in severe

personal injury or equipment damage. To prevent

accidental startup, disconnect the hydraulic power

before beginning any inspection or installation task.