16 ► MBX15 User Manual

Initsmostextreme forms,thecombinationof surface

damageandseverebendingcanquicklybreakeventhe

bestworkingsteels.

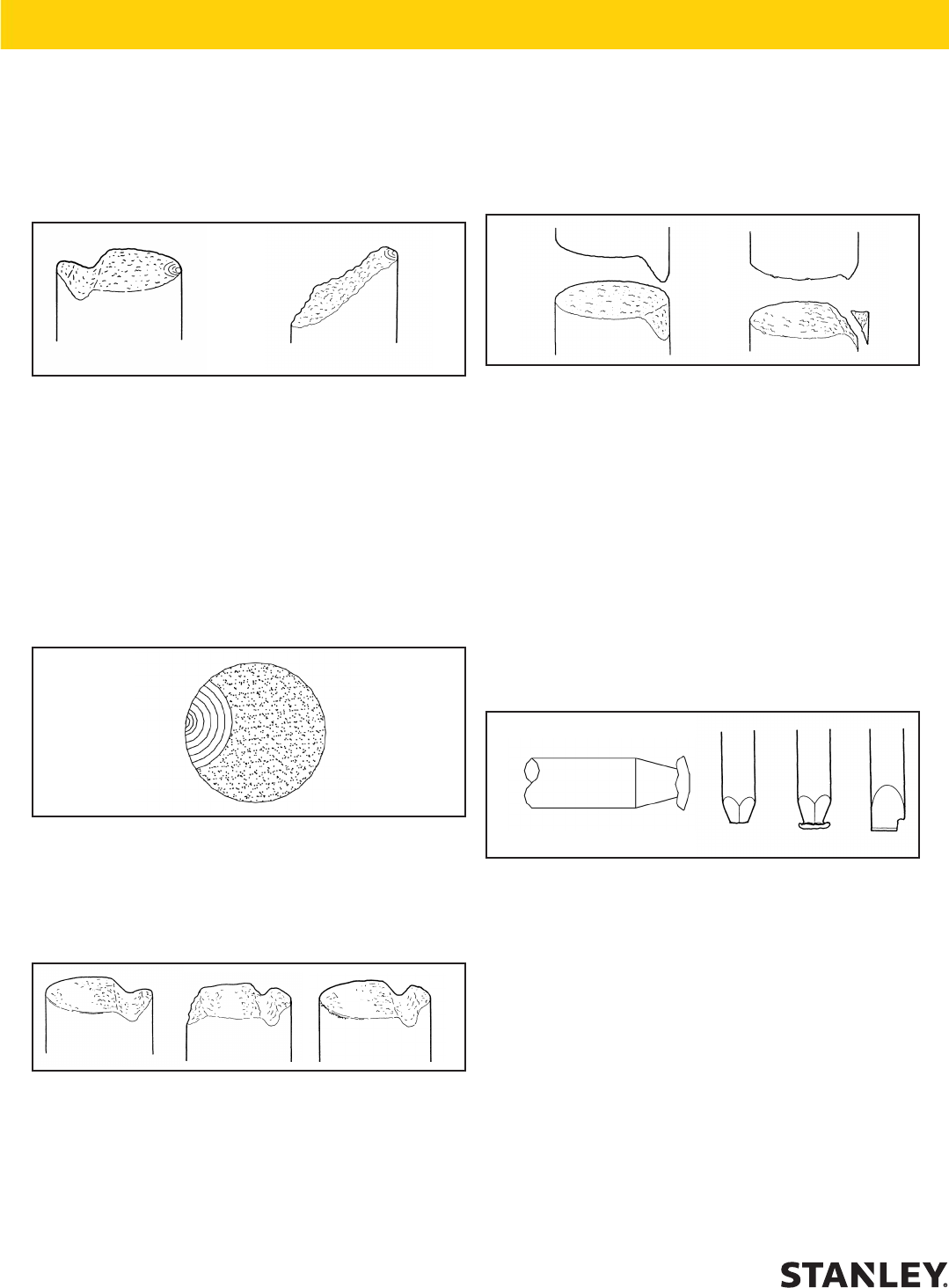

Theillustrationsbelowshowexamplesofseverestress

breaks.

Figure15.SevereStressBreaks

PRYING

This is the most common cause of tool failure. Even

whenthereisnosurfacedamage,thestressfrompry-

ingcaneasilybreakaworkingsteel.Thiskindoffailure

generallyresultsfromanytypeofsidepressuresuchas

anincorrectbreakingangleorfromusingthetooltore-

positionmaterial.Thetoolshouldnotbeusedasapivot

pointwhenrepositioningthecarrier.Thepowergener-

atedbythecarrierwillfarexceedthestrengthofthetool.

Figure16.PryingDamageExample

Similarfailurescanalsooccurwhenthesteelisused

with extreme down pressure, and the steel repeated-

lyslipsofftheworkatanangle,orthematerial,itself

movesfromundertheworkingsteel.

Figure17.ExtremeDownPressureBreakage

Asthenextillustrationshows,fatiguefailurestakemany

forms,buttheyallexhibitsimilarfeatures.Generally,the

brokensurfaceisbrittleandhasa“lip”likethatinthe

bendingfailure,eventhough,insomecases,theliphas

beenbroken.

Figure 18. Fatigue Failures

CORROSION

Toolsshouldbegreasedandstoredoutoftheweather.

Corrosiontendstoacceleratethefatiguefracturesofthe

tool.

MUSHROOMING

Drivingthetoolintoahardmaterialforalongperiodof

timegeneratesanintenseheat,indicatedbyabluetone

justabovethepoint.Thiswillsoftenthesteelandcause

thepointtofoldoverormushroomtheendofthetool.

Avoidhammeringinonelocationfortoolong.Ifmaterial

doesnotbreakafterashortperiod(approximately15to

20seconds),repositionthetool.

Figure 19. Mushrooming

If the overheated steel is suddenly cooled by being

dipped in standing water, for example, the metal will

hardenandbecomebrittle.Thesearesomeexamples

offailurecausedbytemperchangesoccurringonthe

job.

PROPER USE & CARE OF TOOL BITS