MBX15 User Manual ◄ 17

TOOL FAILURE COVERED UNDER

WARRANTY

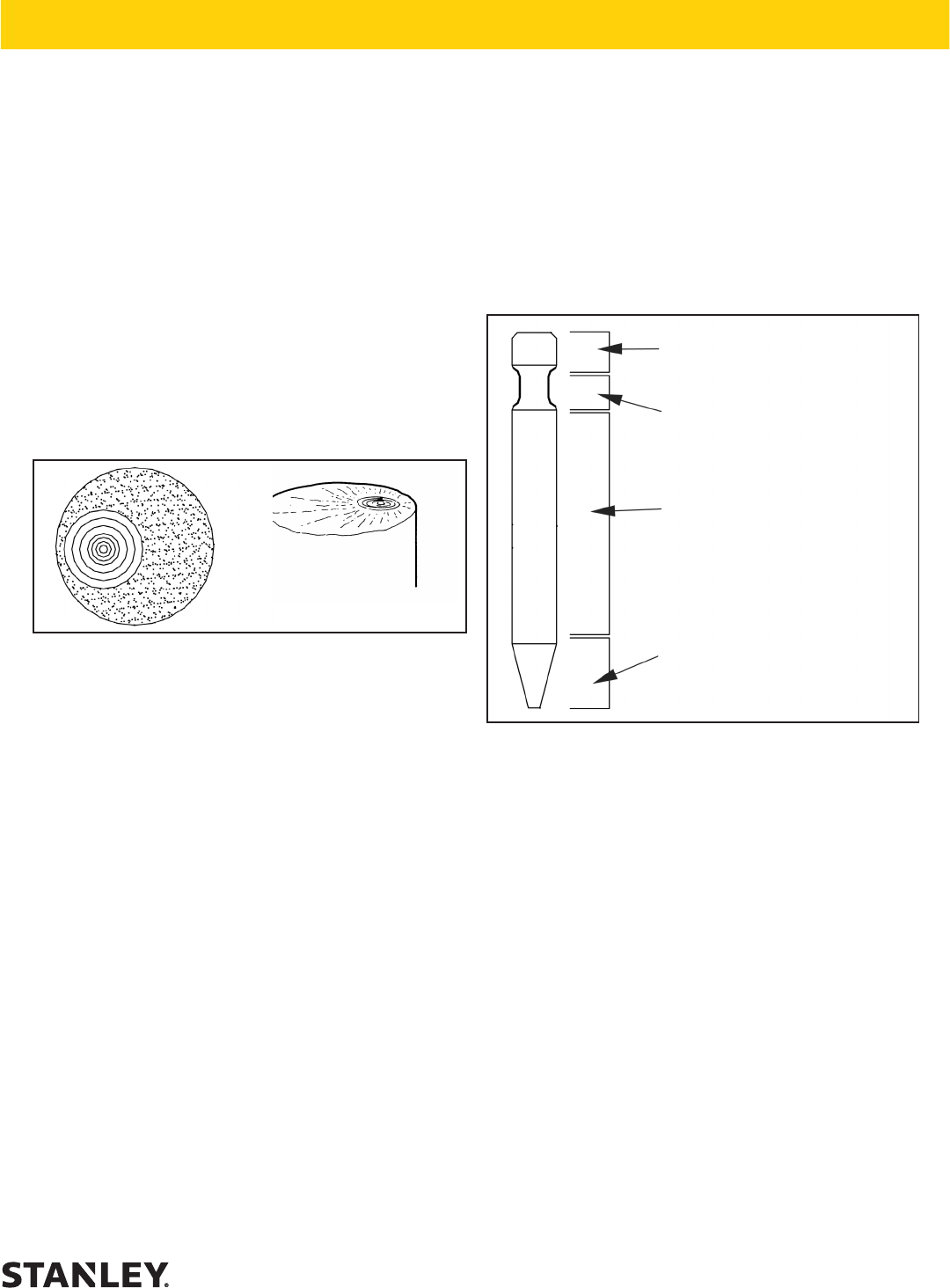

INTERNAL MATERIAL FLAW

Thisfailureoccurswhenaforeignmaterialisrolledinto

thesteelduringthemanufacturingprocess,causingan

imperfectionintheinternalmaterialawgrain.There-

sultisaninherentweaknessinthetoolshankandeven-

tualbreakage.

Thefatiguefailureisstartedbythedefectswithinthetool

bit.Thebrokensurfaceexhibitsashellpatternaround

thestartingpointoffailure,likethatinthefatiguefailure.

Theotherpartsofthebrokensurfacearebrittle.

This is the only kind of tool bit failure that is always

covered under warranty.

Figure 20. Internal Material Flaw

Asarule, workingsteelfailures canbediagnosed by

lookingatthebreakitself,andattheplaceonthesteel

wherethebreakoccurred.Discoloration,like“rainbow”

effectsorbluebands,istheresultofextremeheat.

Lookforsurfacecracks,galling,orgougemarks.Breaks

thatstartassurfacedamagehavea“seashell”pattern,

withthedamagedspotatthecenter.Alarge“seashell”

indicatesaslowgrowing break;asmallone indicates

onecompoundedbysidestress.

Stress failures startsmall, and spread into the center

ofthe steel. In a stressfailure, the coarser the grain,

thegreaterthestresswas,andthemorerapidwasthe

failure.

• Failures in this area are usually the result

ofblankring,wornbushing(s),wornre-

tainerpin(s)orthelackoflubrication.

• Failures in this area are usually the result

ofwornretainerpin(s)orblankring.

• Failures in this area are usually the result

ofprying,metal-to-metalcontactorcorro-

sion.Pryingfailuresoftenexhibitashell-

likeformationneartheedgeofthesteel

diameterwherethe breakbegan,and a

“tail” opposite that where the remaining

steelbentandtore.

• Failures in this area are usually the result

ofheatbuild-up,mushrooming,orimprop-

ercontactwiththework.

Figure21.DiagramofToolBitFailures

PROPER USE & CARE OF TOOL BITS