8 ► MBX15 User Manual

PREPARATION FOR OPERATION

NITROGEN CHARGE

Thebreakerhasbeenproperlychargedwithnitrogenat

thefactoryandisreadytouse(seepage20)forcharg-

inginformation.

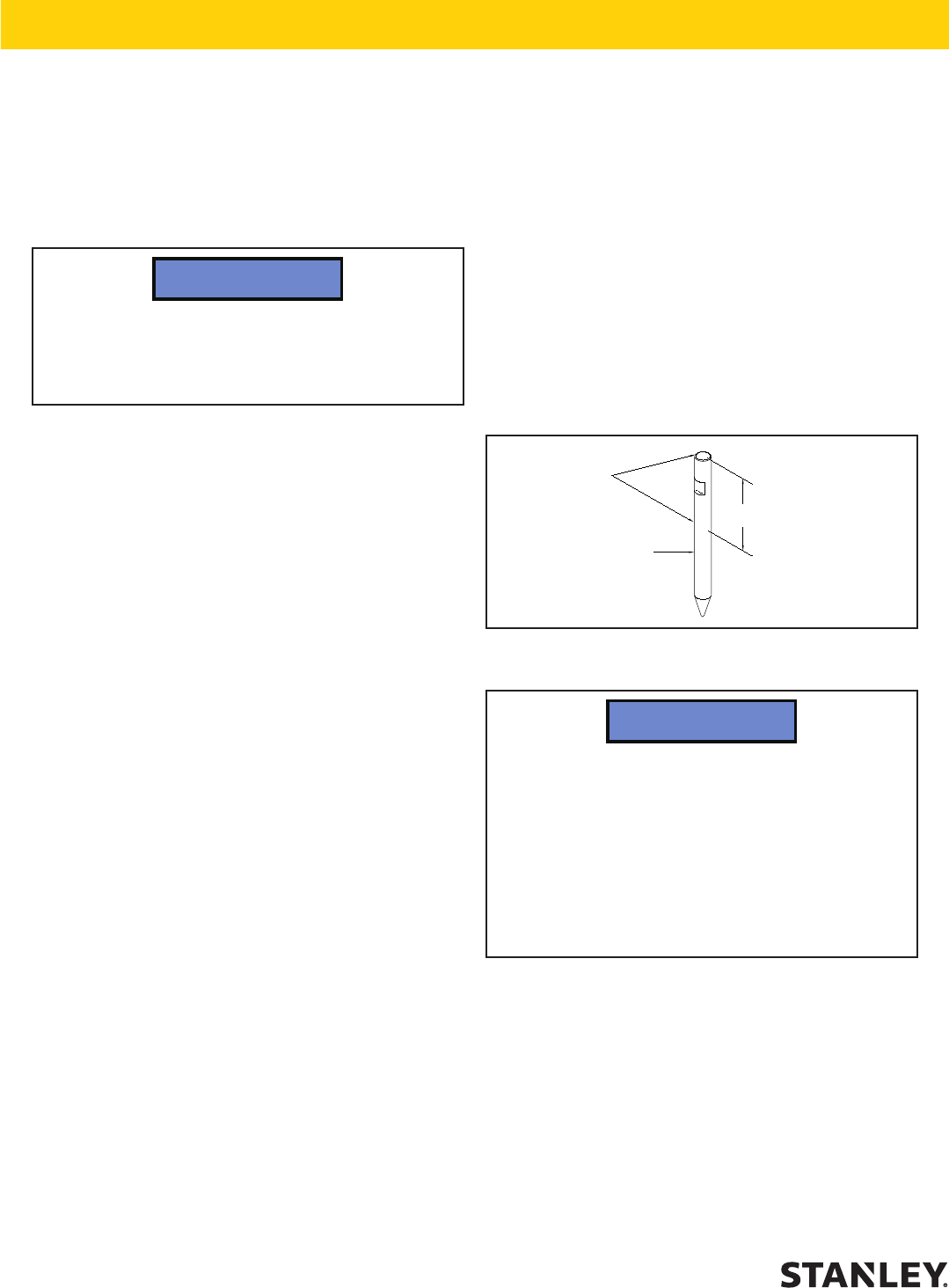

TOOL BIT LUBRICATION

Greasethetop250mm/10inches ofthebreakertool

bitbefore installing. Duringoperation, the tool canbe

greasedthroughthegreasetting.Greaseasrequired.

Make sure the tool bit is against the tool stop by

placing the tool bit against the ground and then put-

ting down pressure on the breaker. SEE THE ILLUS-

TRATION BELOW AND ON THE FOLLOWING PAGE.

ToolBit

250 mm/10 in.

GreaseThis

AreaofBit

Figure1.GreasingtheToolBitBeforeInstallation

NOTICE

Greasing the tool bit without down pressure on

the tool will result in grease lling the space

between the piston and the tool bit.

When the breaker is next activated, the piston

will strike the grease at a speed that will cause

the grease to apply great force against the seals

and grease zerk resulting in damage to these

components.

PRE-INSTALLATION INSTRUCTIONS

EXCAVATOR SIZE

ContactStanleyHydraulicToolstodeterminecorrectex-

cavatorsize.Seethe"SPECIFICATIONS"sectionofthis

manualforhydraulicowandpressurerequirements.

NOTICE

Ifhydraulicpressure,hydraulicback-pressure,

hydraulicow,orexcavatorweightclassare

exceeded,thetoolwarrantyisvoid.

EXISTING EQUIPMENT HYDRAULICS VS

APPLICATION ATTACHING KITS

Using existing equipment hydraulic auxiliary systems

foroperatinghydraulictoolscouldcauseproblemsfor

thehydraulictoolandthehydraulicsystemifnotsetup

properly.Simplypluggingintothehydraulicsystemwith-

outconrmingpressureandowtothehydraulictoolis

notagoodpractice.Sparespoolvalves,dippercircuits,

etc.,are just a fewexamples of easily accessible hy-

drauliccircuitswhichcouldprovetocauseproblemsfor

hydraulic tool usage.

ATTACHINGKITSadapttoexistinghydraulicsystems

ofmanypopularbackhoesandexcavators.

Ifyourequipmentdoesnotcontainanattachingkit,ask

your Stanley dealer for information, installation, and

pricingonakitwhichmatchesyourequipmentneeds.

TEST THE HYDRAULIC SYSTEM

1. HaveyourStanleydealertesttheexcavatorhydrau-

licsystemtomakesurethesystemisoperatingat

themanufacturersspeciedcapacityandpressure

ratings.

2. Besuretheuidinthehydraulicsystemisclean.

3. Checkthehydrauliclter.Replacethelterifdirtyor

deteriorated.

4. Haveyour Stanley dealertest thecircuit to which

thebreakerwillbeconnectedtomakesurethatthe

circuitissupplyingthespeciedowandpressure

rating for the breaker. See the SPECIFICATIONS

sectionofthismanual.

PRE-OPERATION