12 ► FG10/PG05 Service Manual

OPERATION

6. Grind a small amount of material at a time adjust-

ing the grinding wheel as necessary by turning the

handwheel.

Note: If the grinder is not loaded against a work sur-

face when the trigger is released, the wheel will take

5-10 seconds to come to a complete stop. Avoid un-

intentional contact of the grinding wheel during the

coast down period.

COLD WEATHER OPERATION

If the grinder is to be used during cold weather, preheat

the hydraulic uid at low engine speed. When using the

normally recommended uids, uid temperature should

be at or above 50° F/10° C (400 ssu/82 centistokes) be-

fore use.

Damage to the hydraulic system or grinder can result

from use with uid that is to viscous or too thick.

PREVENTATIVE MAINTENANCE

1. The gears and bearings in the ram, spindle, and

housing assemblies should be regreased every 6

months or 500 hours, This procedure must be ac-

complished by a trained technician.

2. After each servicing, measure the spindle speed

(rpm - revolutions per minute) at 12 gpm/45 lpm in-

put. The nominal speed is 4000, not to exceed 6000

rpm. This procedure must be accomplished by a

trained technician.

3. Inspect the spindle and drive ange for signs of

wear or damage. Runout should not exceed .004

in./.1 mm TIR on threads or .002 in./.05 mm TIR on

arbor diameters and faces.

4. Check hoses and ttings weekly for any evidence of

leakage, cover wear, cracking or cuts. If any of these

defects are found, discontinue use of the tool imme-

diately and have the defects repaired or replaced by

a trained technician.

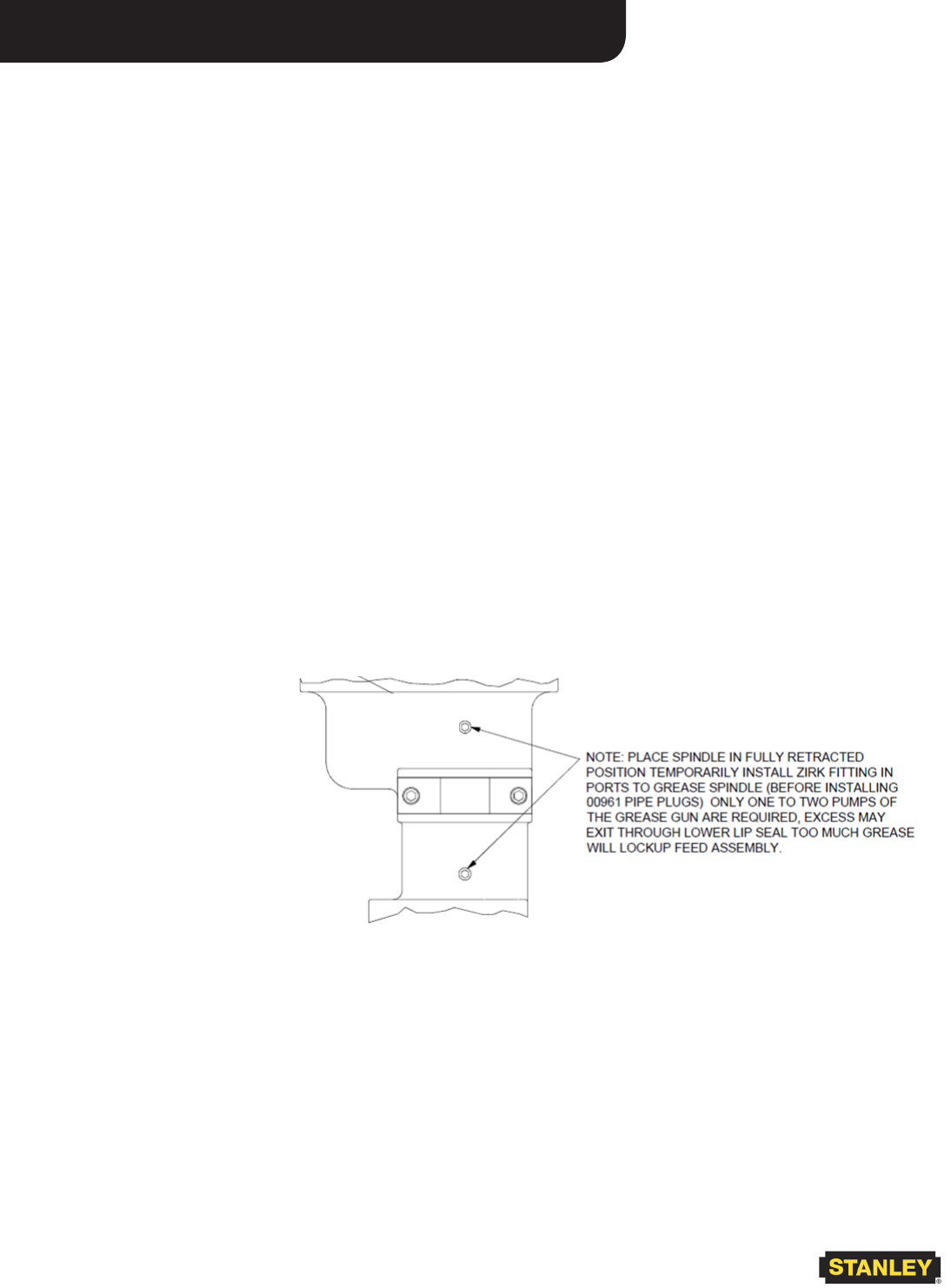

5. To grease between main housing bore (item 73) and

the ram outer diameter (item 26) use CAUTION only

one to two pumps of grease are required at these

locations, excess grease will lockup feed assembly

(See gure 4 below).

Figure 4