12 ► RS25 User Manual

OPERATING PROCEDURES

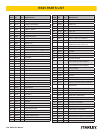

CLAMPING THE RAIL SAW TO THE RAIL

1. Observe all safety precautions.

2. Make sure the rail clamp assembly is tight to the

disconnect pivot (60) by turning the handle (20) to

tighten the disconnect pivot bolt.

3. Fully extend the indicator rod located on the clamp

and position the rail clamp on the rail so the clamp

arms bear on the top and sides of the rail and the

bell crank bears under the rail as shown in Figure 2.

LOWER

CAPSCREW

BELL

CRANK

CLAMP

CLAMP

Figure 2.

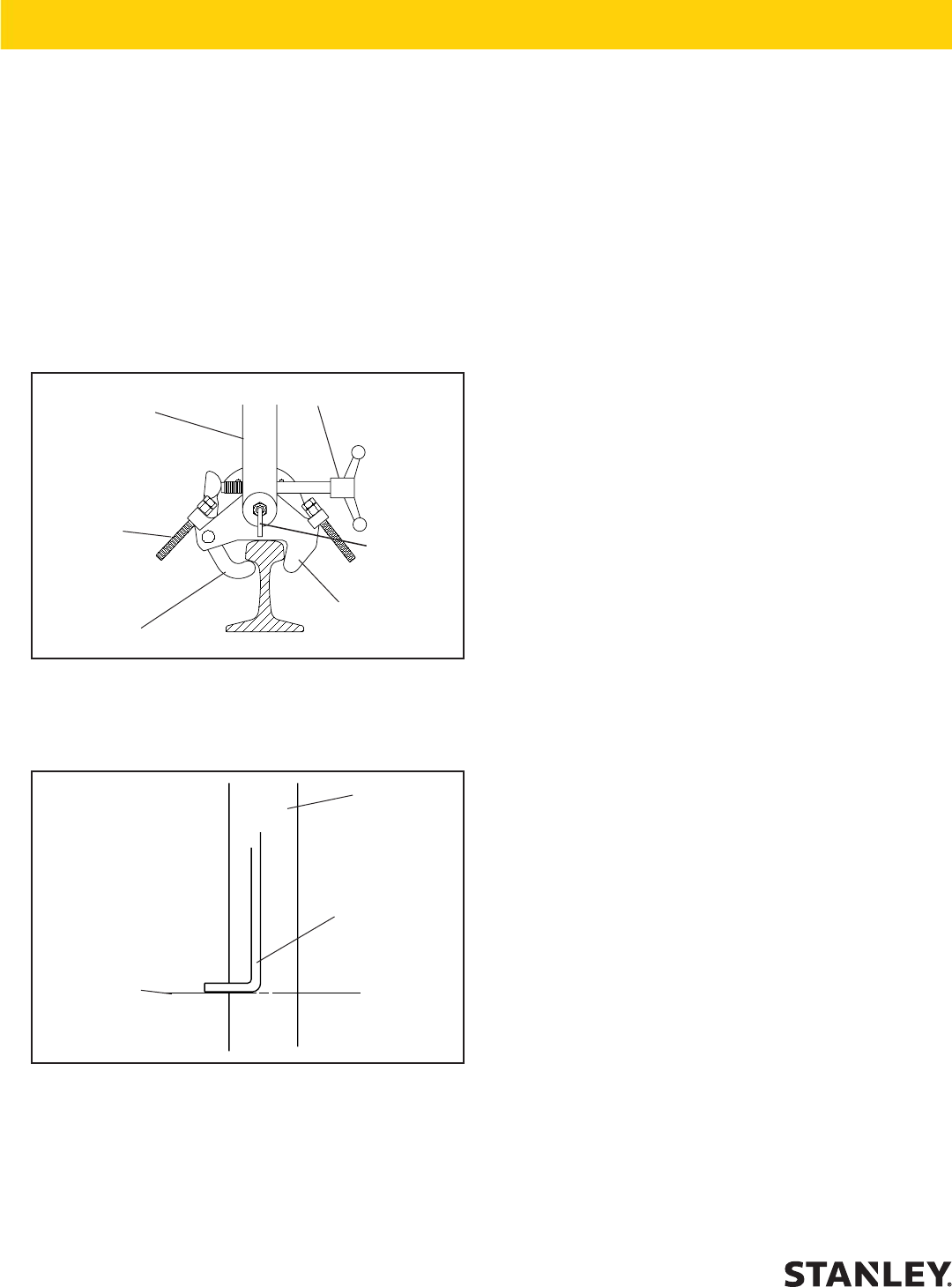

4. Move the rail saw along the rail until the indicator is

next to the cut as shown in Figure 3.

RAIL

EDGE OF

CUT LINE

INDICATOR

Figure 3.

5. Tighten the bell crank to the rail by turning the clamp

screw (75) clockwise.

6. While holding onto the upper link of the rail clamp

assembly (near the red knob of the handle), release

the detent (129) by turning the knob and then posi-

tion the lower link forward (away from the operator)

until the detent can be re-engaged in one or the oth-

er of the two holes away from the “top dead center

hole”. This positions the saw so that the operator

may stand erect while cutting the rail and also allows

the saw to cut down to the ange of the rail.

An optional method is to disengage the detent and

adjust the capscrews (see Figure 2) as required.

7. Adjust the wheel guard (87) so that it does not in-

terfere with the cutting process and cuttings are di-

rected away from the operator.

SAWING THE RAIL

1. Always start the rail saw with the cutting wheel away

from the work surface.

2. Start the cut with the wheel rotating.

NOTE:

Do not “bump” the rail. Feed the wheel through

the material as fast as possible without allowing

the wheel to reduce its speed. Cutting through the

material too slowly allows heat expansion and can

cause wheel “pinching” in the material. “Pinching”

the wheel from heat expansion is one of the most

common causes of wheel breakage.

3. Starting at the top of the rail, cut straight down while

rocking the handle back and forth. Cut down until

near the ange.

4. When near the ange, stop the saw, release the de-

tent and move the lower link toward the operator un-

til the detent can be re-engaged in one of the holes

away from the “top dead center hole”. This positions

the saw lower so that the ange of the rail may be

easily cut.

If the detent has been removed in favor of using the

capscrews as stops for the lower link, simply move

the lower link toward the capscrew closest to the op-

erator.

If the wheel is worn such that it will not completely

cut through the rail, loosen the clamp lever on the

saw, and rotate the saw to allow cutting from the op-

posite side. Readjust the lower link as required and

nish the cut.

INDICATOR

ROD

OPERATION