RS25 User Manual ◄ 15

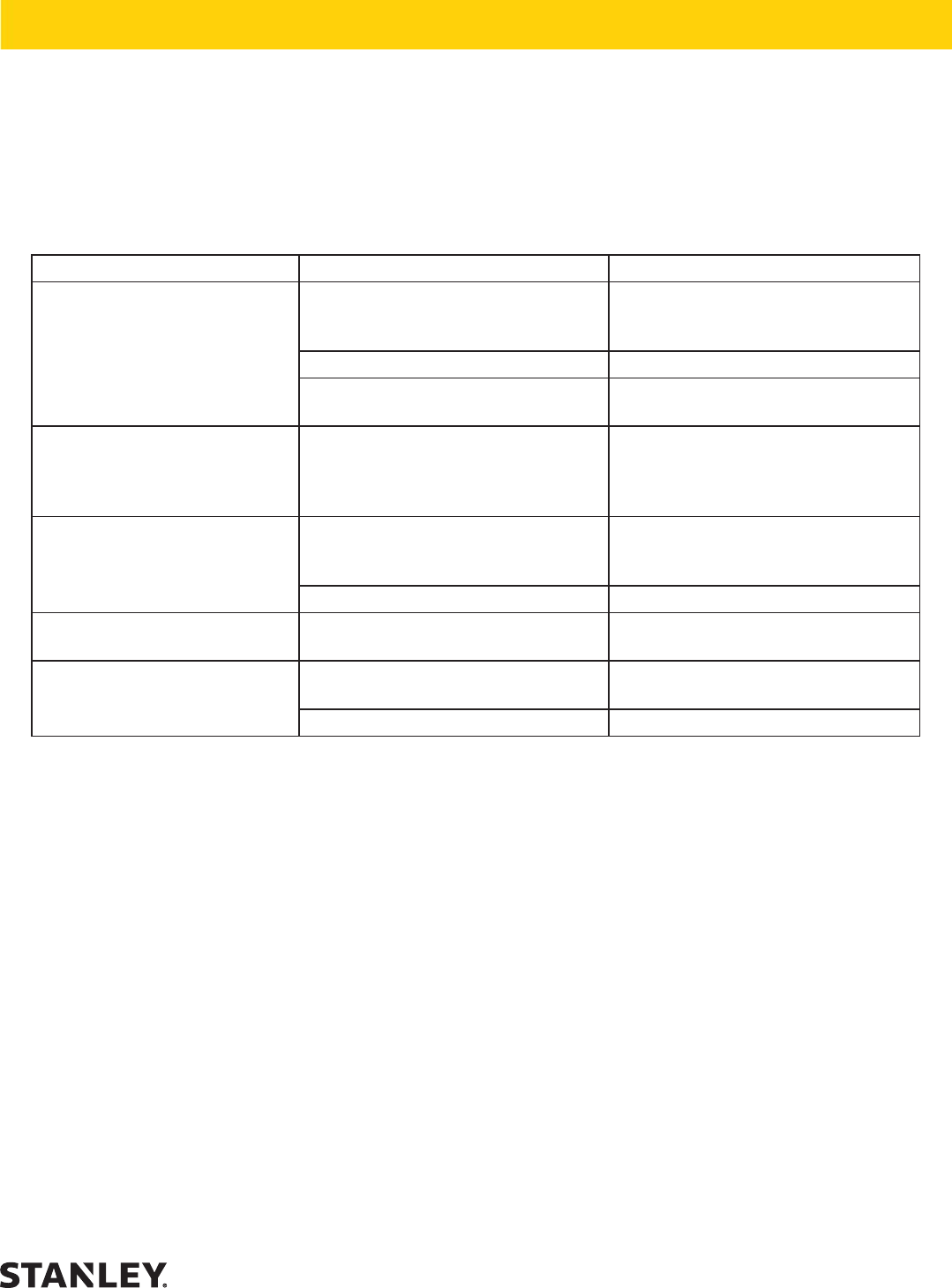

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the grinder, always check that the hydraulic power source is supplying the

correct hydraulic ow and pressure to the grinder as listed in the table. Use a owmeter known to be accurate.

Check the ow with the hydraulic oil temperature at least 80 °F/27 °C.

SYMPTOM POSSIBLE CAUSE SOLUTION

Saw does not run. Hydraulic power source not

functioning correctly.

Check power source for proper ow

and pressure (7–10 gpm/26–34 lpm,

2000 psi/140 bar.

Coupler or hoses blocked. Remove obstruction.

Mechanical failure. Have tool serviced by authorized

dealer.

Saw runs backwards. Pressure and return lines incorrectly

connected.

Correct hose connections. Motor

shaft rotates counter-clockwise as

viewed from the end of the motor

shaft.

Saw cuts too slow. Insufcient uid ow or too high back-

pressure or relief valve set too low.

Check hydraulic supply. If hydraulic

supply is correct, have unit serviced

by authorized dealer.

Wrong wheel for material being cut. Use correct wheel.

Fluid leakage. Seal failure. Do not use. Have serviced by an

authorized dealer.

Off-center cut and binding. Bearings worn on link arms. Have unit serviced by an authorized

dealer.

Incorrect cutting technique. Review operating procedures.

TROUBLESHOOTING