Additive Feeders Chapter 4: Operation 30 of 50

Viewing or Changing the Program Minimum Setting

1. Enter the programming mode, then flip DIP switch 2, Program Minimum Setting,

to ON.

2. The current value for the lower limit FACTORY SETTING = 0 will appear in the

LED display.

3. Use the Up or Down buttons to change the lower limit, as desired.

4. When finished, flip DIP switch 2 to OFF.

5. The display should read PROG.

Viewing or Changing the Program Maximum Setting

1. Enter the programming mode, then flip DIP switch 3, PROGRAM MAXIMUM

SETTING to ON.

2. The current value for the upper limit FACTORY SETTING = 70 will appear in the

LED display.

3. Use the Up or Down buttons to change the upper limit, as desired.

4. When finished, flip DIP switch 3 to OFF.

5. The display should read PROG.

Exiting Programming Mode and Returning to Run Mode

1. Make sure DIP switches 4, TIME/RATE MODE SELECT, and 5,

MASTER/FOLLOWER MODE SELECT are in the desired positions factory

Setting 4 = 1, 5 = OFF, ON FOR OPTIONAL EXTRUDER TRACKER

CONTROLS BEFORE entering the RUN mode (DIP switch 7 OFF).

2. Make sure DIP switches 1 through 4 are OFF.

3. If satisfied with the programmed values, flip DIP switch 7 to OFF.

4. Control should begin to operate normally, using the values and modes selected.

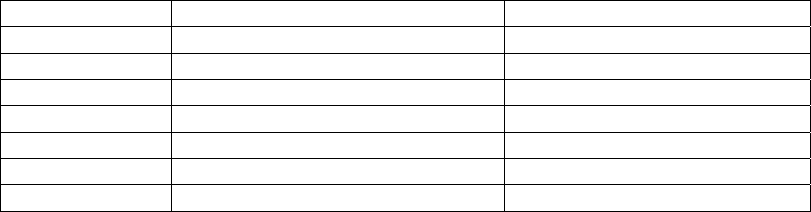

Figure 3: DIP Switch Function Table

Switch 1

Program Constant

Switch 2

Program Minimum Setting

Switch 3

Program Maximum Setting

Switch 4

Decimal Select

0 – 4 = Decimal Points

Switch 5

Master/Follower Select

OFF = Master ON = Follower

Switch 6

Do Not Use – Set to OFF

Switch 7

Program/Run Select

OFF = Run ON = Program

Switch 8

Do Not Use – Set to OFF