14 Finish 230 AC Compact

GB

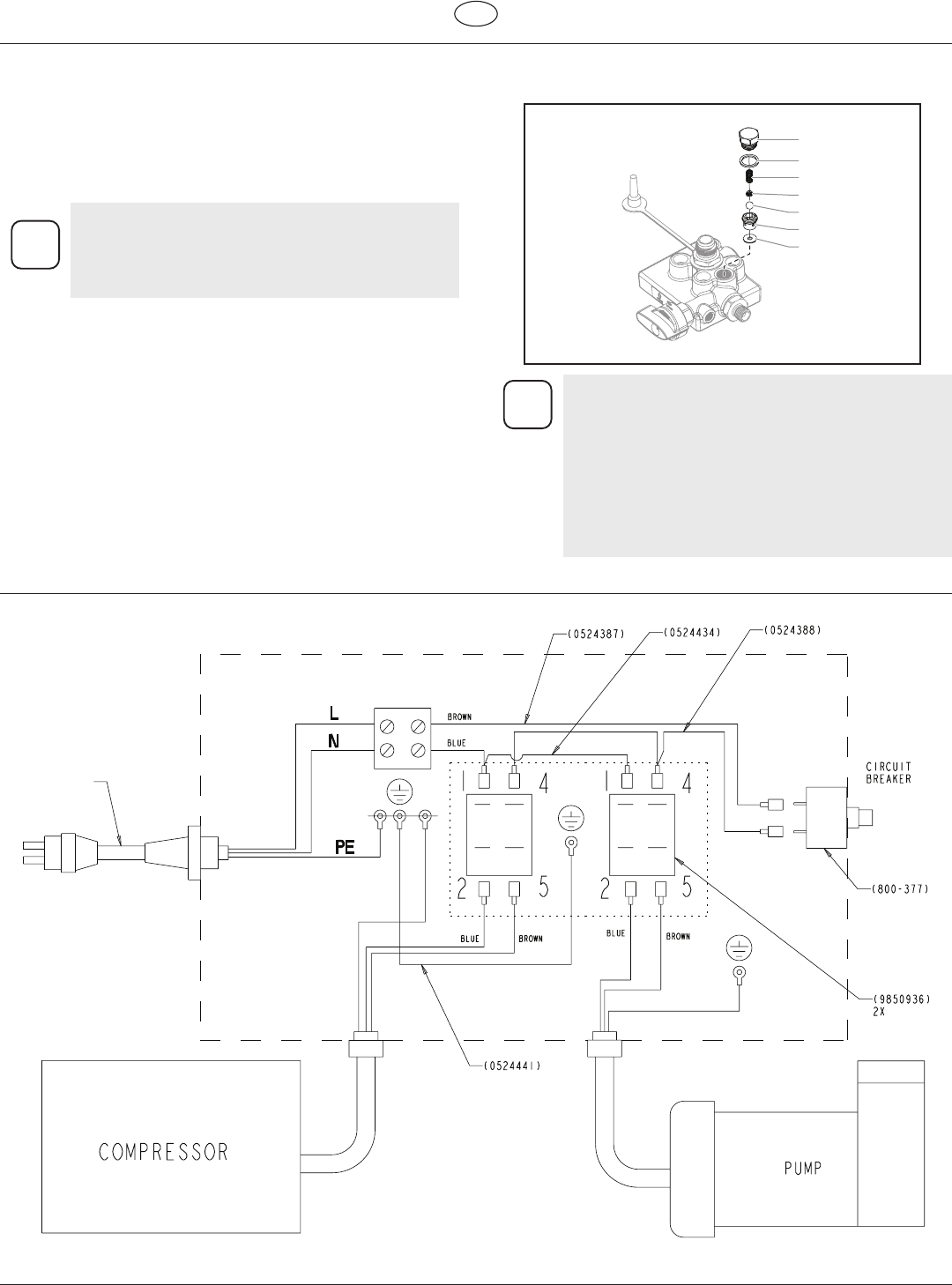

Maintenance Electrical Schematic

8. Tightentheoutletvalvenut(a)securelywithanadjustable

wrench. Do not over-tighten.

(b)

(a)

(c)

(d)

(e)

(f)

(g)

i

Wear on the ball is almost impossible to detect

visually. To test for a worn outlet valve assembly,

turn the pressure control knob clockwise to its

highest setting and run water only through the

pump for 10 to 15 minutes without triggering the

gun.

If the valve is defective, the end cap will get very hot

to the touch. If it is functioning properly, it will stay

approximately the same temperature as the water

running through it.

8.2 Removing and Cleaning the Outlet Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Removetheoutletvalvenut(a)withawrench.

2. Removeandcleantheballstop(d)andsmallspring(c)inside

thevalveusingawirehookortweezers.Replacethespringif

it is broken or worn.

i

This spring is manufactured to a very specic

tension. Do not stretch the spring. Do not put in

an unauthorized substitute. See the paint pump

assembly parts diagram for the proper replacement

part number.

3. Removetheseat(f)andball(e)assembly.

4. Clean all parts thoroughly. If the ball or seat show any sign of

wear or damage, replace them with new parts. This carbide

ball must seal tightly against its seat for the valve to function

properly.

5. Cover all parts with a thin coat of light oil before reassembling.

6. Dropinthevalveball(e).

7. Inserttheprotector(f)andspring.BesurethattheO-ring(b)is

positioned properly and that the tongue on the cap ts inside

the spring.

(See parts list)

9. Electrical Schematic