Maintenance

F

ollow these procedures when encountering problems

i

ndicated in the troubleshooting section.

Removing and Cleaning the Inlet Valves

1. Perform the Pressure Relief Procedure, turn off and

unplug the unit.

2. Remove the inlet valve assembly using a 27 millimeter

socket or box end wrench.

3. Test movement of the valve by pushing on it from the

open end of the valve housing with a screwdriver or the

eraser end of a pencil. It should move about 1/16 of an

inch (0,15 mm). If it does not move, it should be cleaned

or replaced.

4. Thoroughly clean the valve assembly with water or the

appropriate solvent. Use a small brush.

5. If the valve has been properly cleaned and water drips out

of the bottom, the valve is worn and needs to be replaced.

A properly seated valve filled with water and held vertically

will not drip.

6. Install a new or cleaned valve in the pump block and then

fill the valve with light oil or solvent.

NOTE: The inlet valve must be oiled after every job.

This will reduce or eliminate priming problems

the next time the sprayer is used.

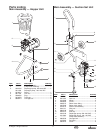

Removing and Cleaning the Outlet Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Remove the outlet valve body with a wrench.

2. Remove and clean the ball stop and small spring inside

the valve using a wire hook or tweezers. Replace the

spring if it is broken or worn.

3. Remove the seat and ball assembly.

4. Clean all parts thoroughly. If the ball or seat show any

sign of wear or damage, replace them with new parts.

This carbide ball must seal tightly against its seat for the

valve to function properly.

5. Cover all parts with a thin coat of light oil before

reassembling.

6. Drop in the valve ball.

7. Insert the ball stop and spring and replace the valve body.

Be sure that the o-ring is positioned properly and that the

tongue on the cap fits inside the spring.

8. Tighten the valve body securely with an adjustable

wrench. Do not over-tighten.

Cleaning the Hopper Screen

The screen at the bottom of the paint hopper

may need cleaning periodically. Check it

every time you add paint. Remove the

screen by pulling it out of the hopper with a

pliers. Clean the screen with water or

solvent and a soft-bristle brush, if necessary.

Valve Body

O-ring

Seal

Seat

Ball

Spring

Ball Stop

NOTE: You will need to align the ridge on the seat

with the groove in the pump housing when

reassembling.

NOTE: This spring is manufactured to a very specific

tension. Do not put in an unauthorized

substitute. See the paint pump assembly

parts diagram for the proper replacement part

number.

© Wagner. All rights reserved. 9

GB

R