11

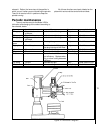

Spindle direction and power feed

The spindle can be driven clockwise or counter-

clockwise. The direction of rotation is controlled by

the control lever on the left hand side of the drill head.

See Fig. 1.

Clockwise or "forward" rotation is the direction

of rotation for right-hand tooling -- which is the vast

majority of tooling used in machine operations.

However, if you use left-hand tooling for any opera-

tions, the spindle direction can be set to counter-

clockwise or "reverse."

The power feed direction is determined by the

spindle direction. When the spindle is set to its most

common direction -- clockwise or forward -- the quill

and spindle are driven downward. When the spindle

direction is set to counterclockwise or reverse

direction, the quill and spindle are driven upward.

Hand feed -- roughing operations

When the feed levers are pushed toward the

drill head the power feed mechanism is disengaged.

In this position, the feed levers can be used to move

the quill and spindle and perform manual drilling or

other machining operations.

Fine hand feed using the power feed

system

The fine feed control wheel is located on the

underside of the right-hand side of the drill head.

See Fig. 1. The fine feed control is used as follows:

1. Set the feed rate dial to N -- neutral.

2. Pull the feed levers out so the power feed clutch is

engaged.

3. Turn the drill press POWER switch ON and set the

control lever so the spindle is turning in the correct

direction for the operation you are performing.

4. Turn the fine feed control wheel by hand. The

quill and spindle will move downward or upward

(depending upon which way you turn the wheel and

the direction the spindle is turning) until you stop

turning the control wheel.

the tooling is installed, you can restablish power to

the machine by turning the cut-out panel back ON.

This will reestablish power to the machine control

system and will allow you to use the motor which

raises and lowers the arm to position the tooling over

the work piece. Raising and lowering of the arm is

controlled by the control stick -- see Fig. 3 and read

page 7,

Raising and lowering the radial arm

.

Power ON light

When the cutout box power is ON, the POWER

light on the upper left hand side of the drill head (Fig.

1) will be lit. In this mode, power to the coolant pump

and to the spindle drive motor is controlled by the

switches on the control console.

Flood coolant control

The flood coolant system provided with the drill

press is turned on by turning the switch to the ON

position. Power OFF to the coolant pump is achieved

by turning the switch counterclockwise to its OFF

position. (If coolant does not flow, check the pump

rotation by observing the pump shaft. It should be

rotating in the direction of the arrow on the pump

casting. If it is not rotating in the correct direction,

see

Electrical,

for more information.)

Spindle motor controls

The power to the spindle motor controlled as

follows:

1. The cutout box control lever must be in the ON

position so power is being fed to the drill press.

2. The two speed spindle drive motor switch must be

in either HI or LOW position.

3. The control ON/OFF switch must be pushed ON.

4. The arm/spindle control lever must be pulled

forward (clockwise rotation) or backward (counter-

clockwise rotation.) See

Using the control lever,

page 11.

Turning spindle drive motor power OFF

To turn power OFF on the spindle drive motor do

one of the following:

1. Put the two speed motor switch in OFF position,

OR...

2. Push the Control ON/OFF switch off, OR...

3. Put the arm/spindle control lever in its middle

(neutral) position, OR...

4. Push the large, red emergency off STOP switch,

OR...

5. When servicing the tooling or other machine

components, put the service disconnect lever in OFF

position.

Once the STOP switch has been pushed (4.,

above) none of the other switches on the panel can

be used to control power to the spindle drive motor or

coolant pump until the STOP switch has been re-set.

Power ON and power OFF

If your Model 1230 was connected to its service

branch correctly, there will be a service disconnect

with an external power cutoff lever or switch which

disconnects the drill press from the service branch.

This is your ultimate protection against accidental

machine start-up when clamping work pieces to the

machine and/or inserting or removing tooling. Always

be certain you have turned off power at this discon-

nect before doing these operations.

Once your workpiece is clamped securely and