15

to the ON position.

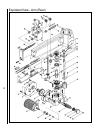

6. Observe the direction of rotation of the

coolant pump. You can see the pump shaft rotate

on top of the pump at the rear of the drill press.

There will be an arrow cast into the pump, and the

shaft should be rotating in the direction of the arrow.

If the shaft is rotating in the wrong direction, the

power is connected, backwards. Correct as follows:

7. Disconnect power to the machine by turning it off

at the cutout box.

8. Reverse

any two

of the power lead connections.

9. Repeat steps 4, 5, and 6, above, and you should

observe the pump shaft turning in the correct direc-

tion. The electrical service to the machine is now

complete.

Caution

Electrical set-up should be performed only by

a licensed electrician who is familiar with national

and local electrical codes.

The Model 1230 is shipped after testing all

functions and circuits under electrical power

specified for the machine and motors. The only

hook-up requirement should be for correct connec-

tion to an appropriate cutout on an appropriate

service branch.

Where the following instructions do not agree

with local electrical codes and procedures, the

applicable codes and procedures should be

followed, exclusively.

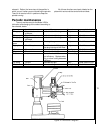

Wiring diagram

A wiring diagram for the drill press is found on

the facing page. This diagram is for reference by

your licensed installing or servicing electrician. In

addition to using a licensed electrician for connection

to the drill press service branch, the servicing of

components and circuits inside the control box should

be serviced only by a qualified electrician. This

includes fuse replacement, if required. If any of

these fuses, upon replacement, should continue to

fail at short service intervals, the electrician should be

asked to check all machine components for excessive

loads, short circuits or other failures.

Electrical

Electrical branch service

The machine is wired for either a 230 or 460 3-

phase service branch. The cable supplying the drill

press will be tagged with the voltage at which the

machine was tested and corresponding to the

customer's order.

If the tag has been lost, it will be necessary for

you to open the electrical cabinet on the rear of the

drill press and examine the connections on the

transformer found inside the box. The transformer

can be connected to either a 230 or 460 volt source

and its taps are labeled for voltage. By locating the

source tap on the transformer you will be able to

determine the branch voltage required.

A service disconnect is recommended. The

use of fuses or circuit breakers for each of the

voltage supply wires is required. Use fuses or circuit

breakers which are appropriate to the voltage for the

motor system delivered.

A positive cut-out/lock-out lever or rocker switch

should be located on the outside of the service

disconnect to allow the machine operator to discon-

nect the machine from the branch circuit when

working with tooling on the machine.

To connect the branch to the drill press

1. Disconnect the service branch to the machine by

moving the lever or rocker switch on the cutout box to

OFF.

2 Connect the green wire (or green with white trace)

to the branch ground.

3. Connect the remaining three wires in the cable

(labeled R,S and T) to the three power lines in the

branch.

4. Turn the power to the machine ON at the cutout

box.

5. Turn the coolant pump power switch (See Fig. 1)