12

Resetting the STOP switch

1. Turn the switch in the direction of the arrow on the

red button -- clockwise. The switch is reset and the

other spindle motor controls can be used.

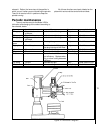

Using the control lever

The four-position control lever is located on the

left hand side of the drill head console. See Figs. 1

and 3.

The control lever can move up or down, back-

ward or forward, or can be left in its most central,

OFF or

neutral

position so no functions are under its

control power.

The control lever moves up or down to move the

arm up or down when positioning the tooling over the

work piece. This ability to control the height of the

arm is available when:

1. The main power to the machine is ON at its

branch service panel.

2. The emergency STOP switch is set to its ON

mode.

3. The Control ON/OFF switch (lower left hand side

of the face of the drill head, see Fig. 1) pushed ON.

4. The column and arm UNLOCK button (right hand

side of the drill head -- see Fig. 1) is pressed to

unlock the machine locks. See page 6.

The control lever does not return to neutral when

it is released. It stays in the position in which you

have placed it. This means unless you return it to

neutral, the arm will keep raising or lowering until it

contacts one of its limit switches.

When the motor speed control switch has been

set to either HI or LOW position, the control lever can

be moved backward or forward to turn the spindle

drive motor ON and control the direction of rotation of

the spindle. The control lever is not spring loaded to

return to the neutral or OFF position when you

Figure 3: Control lever for spindle and arm.

Tapping operations

When performing tapping operations :

1. Determine the most efficient tapping speed

(spindle speed) by consulting appropriate machinist's

tables, your tap supplier, coolant supplier and/or work

piece supplier.

2. Be certain the power feed dial is in N or neutral

position. See

Setting power feed rate

, page 8.

3. Turn the spindle motor ON. Also, turn on the

coolant pump if coolant is being used.

4. Move the control lever to FORWARD.

5. Use the feed levers to move the tap into its pilot

hole until the tap makes its initial thread cut and is

engaged in the workpiece.

6. Allow the tap to "self feed" into the pilot hole until it

has completed its tapping operation.

7. Move the control lever into its center/neutral

position until the spindle has come to a complete

stop.

8. Move the control lever into its reverse direction so

the tap unscrews itself from the hole it has just

threaded.

Using the load ammeter

An ammeter on the control console is used to

monitor the load on the spindle drive motor. It is

connected into one of the three power lines which

supply the main drive motor.

When the drive motor is ON and up to speed,

and there is no tooling being used to drill, tap or bore

a hole, the ammeter should read approximately 2.5

amps. If it is above this value there is a problem

internally (such as lack of lubrication in the gear-

boxes, bad bearings, etc.) which means you should

turn off the machine and determine the cause of the

excessive free-running load.

Monitor the the ammeter during machining

operations. The ammeter should stay below 9 amps

or current draw during machining. You should adjust

your spindle speed, feed rate and coolant use to

maintain the full load current draw below the 9 amp

value.

If you exceed 9 amps current draw a thermal

limiter switch in the electrical control panel will trip. If

this occurs, a licensed electrician should be used to

locate and re-set the thermal limiter switch.