6 720 608 263

Maintenance and service

29

5.3 Mineral scale build-up

Periodic descaling may be necessary in areas with high

mineral content in the water. Scale buildup in the heat

exchanger may result in lower flow rates, error codes of

A7 and E9 and boiling sounds in the heat exchanger.

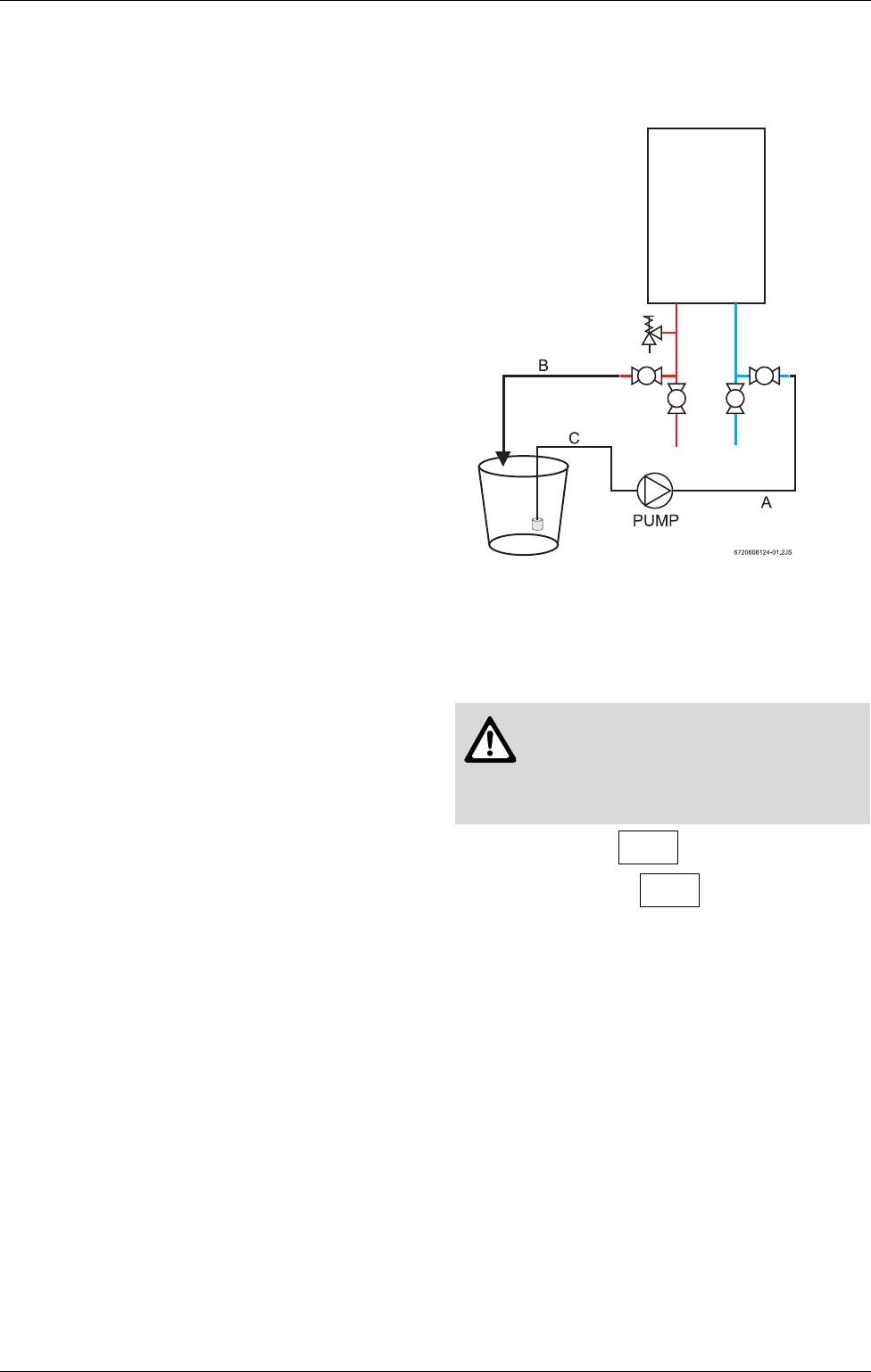

Descaling using a pump

1. Disconnect electrical supply from the water heater.

2. Shut off the water supply to the water heater using

(installer supplied) shut-off valve.

3. Open hot water taps to drain and relieve pressure

from the plumbing system.

4. Drain water from the unit's heat exchanger by

disconnecting inlet and outlet water connections

from the heater.

5. Connect a line (A) from the outlet of the circulating

pump (installer supplied) to the inlet water fitting on

the water heater.

6. Connect another line (B) to the water outlet fitting on

the water heater. Route the other end of this line into

a descaling reservoir.

7. Using a 3rd line (C) from the descaling reservoir,

connect to the inlet side of circulating pump. Install a

filter on the end of the line in the descaling reservoir.

8. Make sure all connections are "hand tight.".

9. Fill reservoir with descaling solution so both lines

inside are submersed. We recommend straight white

vinegar. If using a commercial descalant, refer to

manufacturer's instructions on dilution with water.

10.Operate the circulating pump.

11.Make sure there are no leaks and the solution is

flowing from the descaling reservoir through the

heater and returning to the reservoir.

12.Run solution through the heater until the solution

returning to the descaling reservoir comes out clear.

(Changing to a fresh solution may be necessary

during this process).

13.Disconnect all lines and drain all solution from heat

exchanger. Properly discard of solution.

14.Position a container below the hot water outlet and

reconnect cold water supply. Open cold water

supply shut-off valve and flush heat exchanger with

clean water.

15.Shut cold water shut-off valve and reconnect hot

water line to the water heater.

16.Reconnect electrical supply to unit, open water

isolation valves, and return the unit to service.

Fig. 39

5.4 Adjusting CO

2

The CO

2

can only be adjusted by a certified gas

technician with a calibrated CO

2

analyzer.

Static Gas Pressure: “ WC

P1 Operating Pressure: “ WC

The P1 minimum operating gas pressure is 5" WC for

Natural Gas and 11"WC for Propane. Do not proceed

in adjusting CO

2

until pressure is at or above these

levels, but not to exceed 14” WC.

A. Once Gas Pressure is adequate

B Turn ON/OFF switch to the OFF (O) position.

B Remove brass flat head screw on the exhaust collar

as seen in Fig. 40.

B Insert CO

2

analyzer probe into the measuring port.

The tip of the probe should be in the center of the flue

Caution: One factor that may affect

CO

2

levels is improper gas pressure.

Please see Chapter 3.8 for the

procedure to measure gas pressure

and record your findings below: