4.

Additional Safety Rules

e. NEVER place your face or body in line with the cutting

tool.

• NEVER place your fingers and hands in the path of the

s

awblade or other cutting tool.

• NEVER reach in back of the cutting tool with either hand to

hold down or support the workpiece, remove wood scraps,

or for any other reason. Avoid awkward operations and hand

positions where sudden slip could cause fingers or hand to

move into a sawblade or other cutting tool.

• DO NOT perform any operation “FREEHAND” — always

use either the rip fence or the miter gauge to position and

guide the work.

• NEVER use the rip fence when crosscutting or the miter

gauge when ripping. DO NOT use the rip fence as a length

stop.

• NEVER hold onto or touch the “free end” of the workpiece

or a “free piece” that is cut off, while power is “ON” and/or the

sawblade is rotating.

• Shut “OFF” the saw and disconnect the power cord when

removing the table insert, changing the cutting tool, removing

or replacing the blade guard, or making adjustments.

• Provide adequate support to the rear and sides of the saw

table for wider or long workpieces.

• Plastic and composition (like hardboard) materials may be

cut on your saw. However, since these are usually quite hard

and slippery, the anti-kickback pawls may not stop a kick-

back. Therefore, be especially attentive to following proper

set-up and cutting procedures for ripping. Do not stand, or

permit anyone else to stand, in line with a potential kickback.

f. If you stall or jam the sawblade in the workpiece, turn saw

“OFF”, remove the workpiece from the sawblade, and check

to see if the sawblade is parallel to the table slots or grooves

and if the spreader is in proper alignment with the sawblade.

If ripping at the time, check to see if rip fence is parallel with

the sawblade. Readjust as indicated.

g. NEVER gang crosscut — lining up more than one work-

piece in front of the blade (stacked vertically, or horizontally

outward on the table) and then pushing thru sawblade. The

blade could pick up one or more pieces and cause a binding

or loss of control and possible injury.

h. DO NOT remove small pieces of cut-off material that may

become trapped inside the blade guard while the saw is

running. This could endanger your hands or cause a kick-

back. Turn saw “OFF” and wait until blade stops.

11. KNOW YOUR CUTTING TOOLS

Dull, gummy or improperly sharpened or set cutting tools can

cause material to stick, jam, stall the saw, or kickback at the

operator. Minimize potential injury by proper cutting tool and

machine maintenance. NEVER ATTEMPT TO FREE A

STALLED SAWBLADE WITHOUT FIRST TURNING THE

SAW OFF.

a. NEVER use grinding wheels, abrasive cut-off wheels, fric

-

tion wheels (metal slitting blades) wire wheels or buffing

wheels.

b. USE ONLY RECOMMENDED ACCESSORIES.

c. Crosscutting operations are more conveniently worked

and with greater safety if an auxiliary wood facing is attached

to the miter gauge. (See Page 64).

d

.

M

ake sure the top of the cutting tool rotates toward you

when standing in normal operating position. Also make sure

the cutting tool, arbor collars and arbor nut are installed prop-

e

rly. Keep the cutting tool as low as possible for the oper-

ation being performed. Keep all guards in place whenever

possible.

• Do not use any blade or other cutting tool marked for an

operating speed less than 4800 R.P.M. Never use a cutting

tool larger in diameter than the diameter for which the saw

was designed. For greatest safety and efficiency when rip-

ping, use the maximum diameter blade for which the saw is

designed, since under these conditions the spreader is near-

est the blade.

e. Make sure the table insert is flush or slightly below the

table surface on all sides except for rear side. NEVER oper-

ate the saw unless the proper insert is installed.

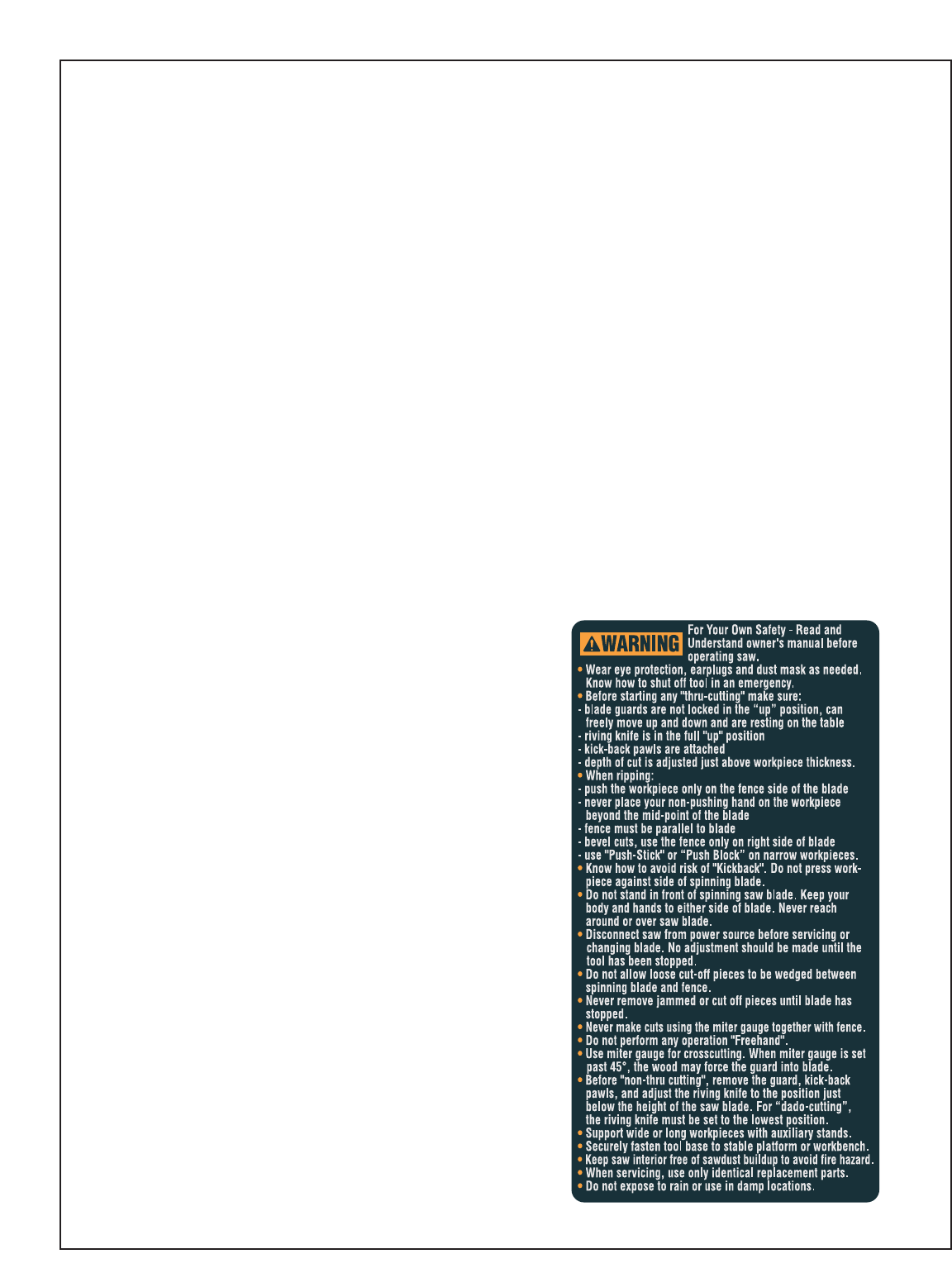

NOTE AND FOLLOW SAFETY

INSTRUCTIONS THAT APPEAR

ON THE FRONT OF YOUR TABLE SAW.