FIG. 74

86

.

Lubrication

The gear case has been completely lubricated at the factory.

However, after six months to one year, depending upon use, it’s

wise to return your tool to the nearest Service Center for the

following:

• Brushes replaced.

• Parts cleaned and inspected.

• Relubricated with fresh lubricant.

• Electrical system tested.

• All repairs.

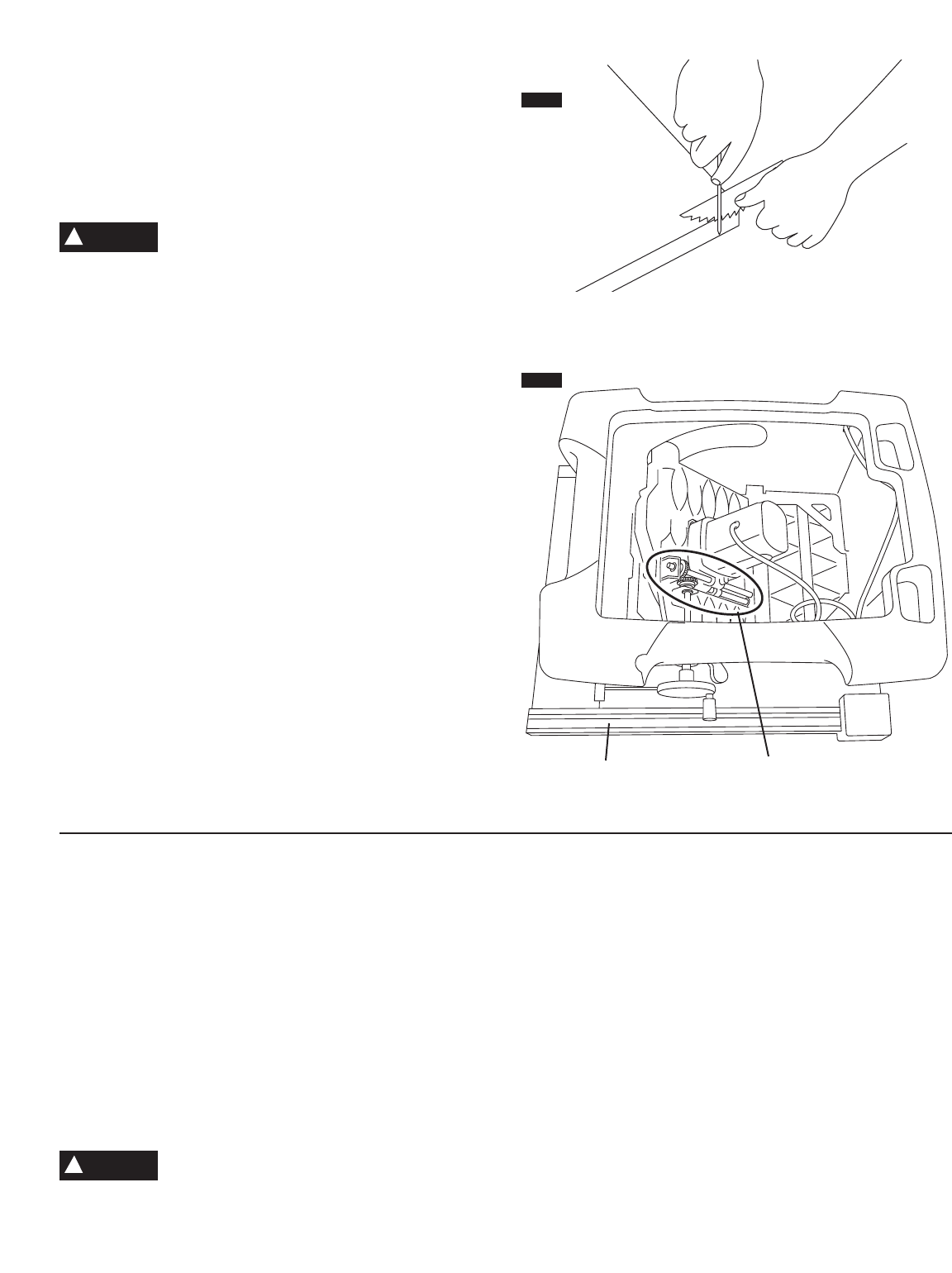

The following parts should be oiled occasionally with SAE No. 20 or

No. 30 oil, or WD 40 (Fig. 74).

1. Elevation, support rods, and gears.

2. Sliding rails and supports.

3. Table locking cams (Front & Rear).

Make sure the teeth of the ANTIKICKBACK pawls are always

s

harp. To sharpen:

1

. Remove blade guard.

2. Rotate pawl toward rear of spreader so that teeth are above top

of spreader.

3. Hold spreader with pawl over corner of workbench (Fig. 73).

4. Using a small round file (Smooth Cut) sharpen the teeth.

All repairs, electrical or mechanical, should be

attempted only by trained repairmen. Contact the

nearest Factory Service Center or Authorized Service Station or

other competent repair service. Use only identical replacement

parts, any other may create a hazard.

Item Cat. No.

Rear Outfeed Support

..................................TS1002

Left Side Outfeed Support ..............................TS1003

Dust bag ...............................................TS1004

Zero Clearance Insert

...................................

TS1005

Dado Insert Set.........................................TS1007

Molding Insert ..........................................TS1009

Pusher Guide System...................................TS1010

Blade Tote..............................................TS1011

Gravity-Rise Wheeled Table Saw Stand

..................TS2000

Use only recommended accessories. Follow

instructions that accompany accessories. Use of

improper accessories may cause hazards.

Recommended Accessories

WARNING

!

1

2

WARNING

!

FIG. 73