2

1

1

“C” CLAMPS

SERRE-JOINTS EN C

ABRAZADERAS EN “C”

WORK SUPPORT

SUPPORT

APOYO DE LA

PIEZA DE TRABAJO

RABBETING ALONG

THE EDGE

RÉALISATION D’UNE

FEUILLURE LE LONG D’UN

BORD

REBAJO A LO LARGO

DEL BORDE

RABBETING ACROSS

THE END

RÉALISATION D’UNE

FEUILLURE EN TRAVERS

D’UNE EXTRÉMITÉ

REBAJO TRANSVERSAL

AL EXTREMO

RABBET

FEUILLURE

REBAJO

FIRST CUT

PREMIÈRE COUPE

PRIMER CORTE

SECOND CUT

DEUXIÈME COUPE

SEGUNDO CORTE

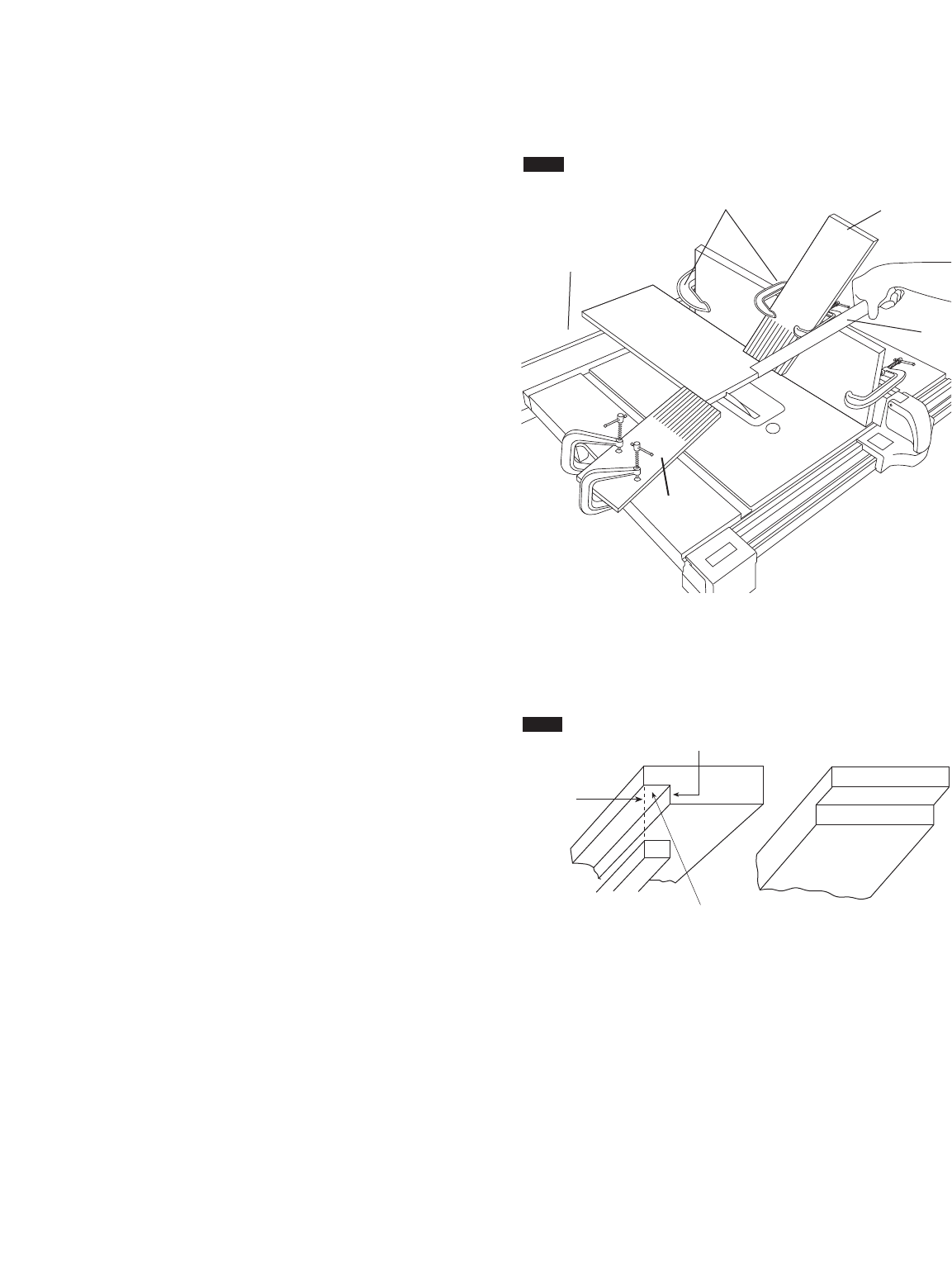

FIG. 66

FIG. 67

76

.

Non Thru-Sawing

A

dd 8" high flat facing board to the fence, the full length of the

fence (Fig. 66).

U

se featherboards for all “Non Thru-Sawing” operations (when

sawblade guard must be removed). Featherboards

1 are used to

keep the work in contact with the fence and table as shown, and to

s

top kickbacks.

Mount featherboards

1 to fence and table as shown, so that

l

eading edges of featherboards will support workpiece until cut is

complete, and the workpiece has been pushed completely past the

cutter (sawblade, dado head, molding head, etc.) with a Push Stick

2,

as in ripping.

B

efore starting the operation (switch saw “OFF” and set cutter

below table surface):

A. Install featherboards so they exert pressure on the workpiece;

BE POSITIVE THEY ARE SECURELY ATTACHED.

B. Make sure by trial that the featherboards will stop a kickback if

one should occur.

Featherboards are not employed during non thru-sawing

operations when using the miter gauge.

REPLACE THE SMART GUARD SYSTEM AS SOON AS THE

NON THRU-SAWING OPERATION IS COMPLETE.

Rabbeting

RABBETING is known as cutting out a section of the corner of a

piece of material, across an end or along an edge (Fig. 67).

Making a RABBET requires cuts which do not go all the way

through the material. Therefore the Smart Guard System must be

removed.

1. Remove blade guard.

2. For rabbeting along an edge (long way of workpiece) as shown,

add facing to rip fence approximately as high as the workpiece is

wide. Adjust rip fence and blade to required dimensions; then

make first cut with board flat on table, follow set-up Fig. 66. Make

second cut with workpiece on edge. Follow all precautions,

safety instructions, and operation instructions as for ripping or rip

type operations, including featherboards and Push Stick, etc.

3. For rabbeting across an end, for workpiece 10-1/2" and narrower

make the rabbet cut with the board flat on the table. Using the

miter gauge fitted with a facing, follow the same procedures and

instructions for crosscutting making successive cuts across the

width of the workpiece to obtain the desired width of cut. DO

NOT use the rip fence for rabbeting across the end.

4. INSTALL SMART GUARD SYSTEM IMMEDIATELY UPON

COMPLETION OF RABBETING OPERATION.

Rabbet cuts can also be made in one pass of the workpiece over

the cutter using the dado head or molding head.