36.

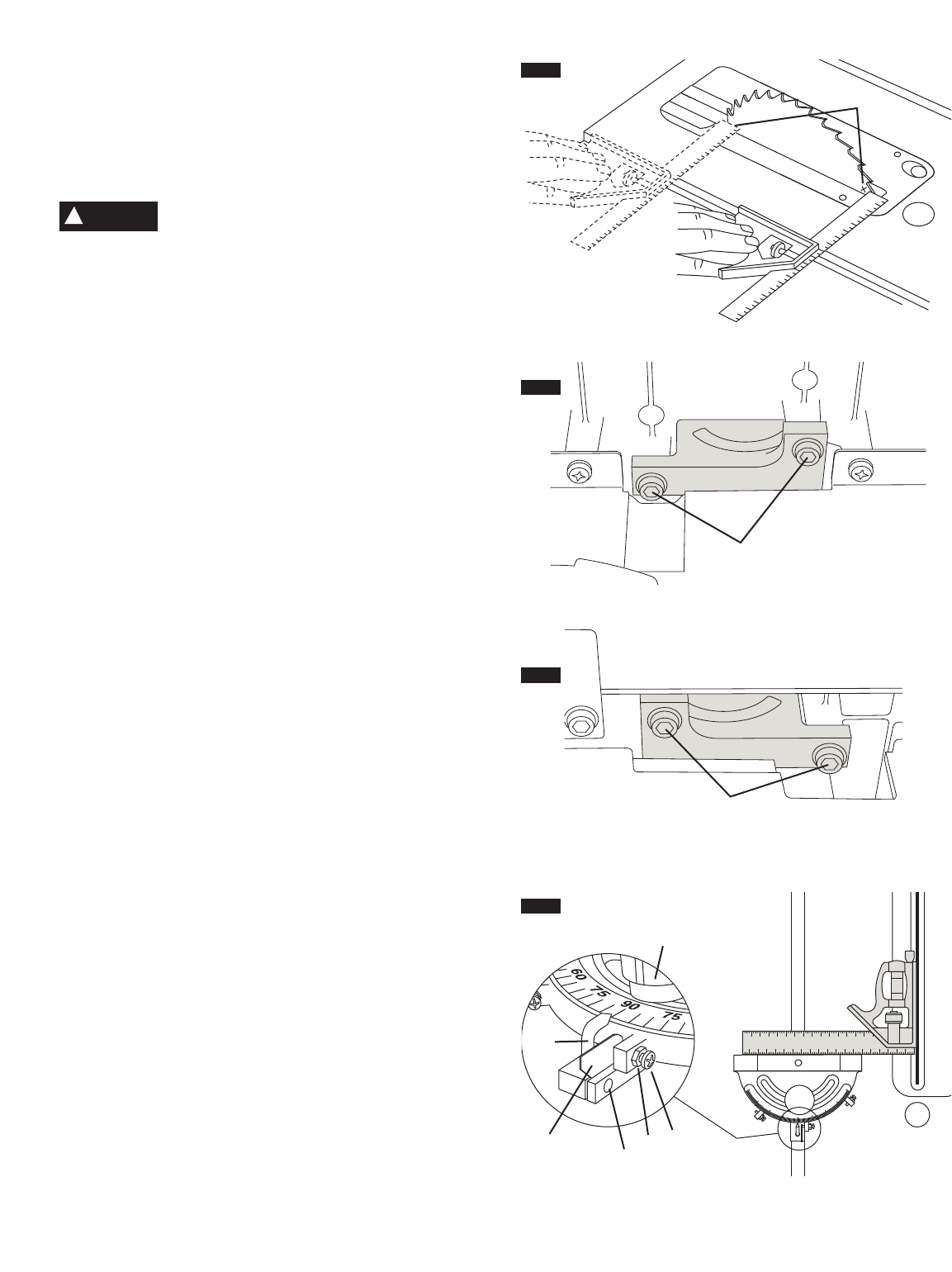

FIG. 19

2

4

8

3

6

FIG. 20

UNDER FRONT OF

TABLE

UNDER REAR OF TABLE

2

FIG. 18

1

Adjusting Blade Parallel To

The Miter Gauge Slots

The blade was adjusted parallel to the miter gauge slots at the

factory. In order to insure accurate cuts and help prevent

kickback, this adjustment should be rechecked. If adjustment is

necessary, follow the steps below.

To prevent personal injury, always disconnect

the plug from power source before making any

adjustments.

1. Turn elevation wheel and raise blade as high as it will go.

2. Select a point on the body of the saw blade that is set to the

left when viewing blade from the front of saw, and mark

1 with a

pencil (Fig. 18).

3. Place the base of a combination square against the edge of

the miter gauge slot, and extend the sliding rule of square so it

just touches the marked point

1 on the body of the saw blade at

the rear of the table.

4. Rotate blade and check the same marked point

1 of the saw

blade at the front of the table (Fig. 18).

5. If the front and back measurements, shown in Figure 18, are

not identical, loosen the four alignment bolts

2, located on the

underside of the table at the front and rear of the saw with hex

wrench supplied with your saw (Fig. 19 & 20). Carefully move

the saw blade until the blade is parallel to the miter gauge slot,

and securely tighten all four bolts.

Miter Gauge Adjustment

To check your miter gauge accuracy, move the miter gauge in

line with blade and use a combination square to make sure the

miter gauge body is 90 degress to the blade (Fig. 21).

To adjust the miter gauge for 90 degrees:

1. Loosen lock nut

3, adjustment screw 4, and lock knob 5.

2. Flip stop plate

6 down.

3. Rotate miter gauge body until it is 90 degrees to the blade.

4. Tighten lock knob

5.

5. Flip stop plate

6 up and tighten adjustment screw 4 until it

contacts stop plate

6.

6. Tighten lock nut

8.

7. If pointer

7 is not pointing to 90 degrees, loosen set screw 8

on side of miter gauge bar and rotate pointer 7 to 90 degrees

mark. Tighten set screw

8.

8. To adjust the miter gauge for 45 degress left and right, repeat

steps 1-6, but use 45 degree stops.

WARNING

!

90

30

45

60

75

75

60

45

30

FIG. 21

5

7