15.

Checking Left 45°

Bevel Stop

1. Lower head assembly and engage head assembly

lock pin.

2.

Slide head assembly completely to the back and

tighten the rail lock knob.

3. Rotate table to the 0° miter position.

4. Pull up bevel lock lever to unlock bevel.

5. Move bevel range selector knob to 45°-0° position.

(See page 28)

6. Tilt the saw assembly to the left, then rotate saw

assembly to the right until you feel the stop in the

45° left position. This is where the saw is current-

ly set for the 45° left bevel cut.

7. Use the head (remove ruler) of a combination

square to check blade at the 45° stop. Place the

combination square head on the table and press

it’s 45° surface against the blade. If the blade does

not contact the full length of the square, (figure 1),

follow the calibrating procedure.

Table

Blade

Combination Square

Bevel Lock

Lever

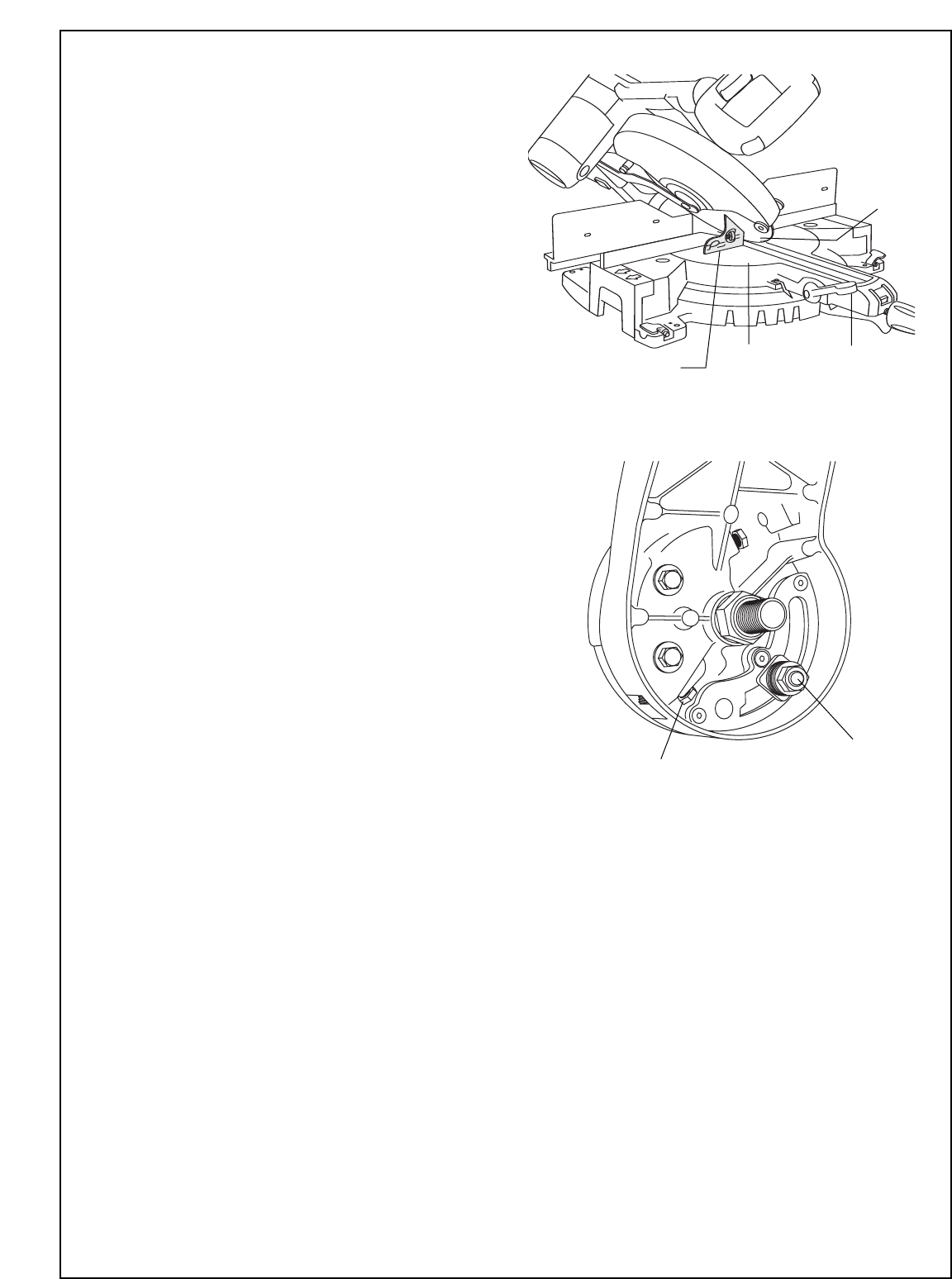

Adjusting Bevel Lock

Lever Tension

1.Lift bevel lock lever to release bevel lock.

2.Place 17mm open-end flat wrench on bolt head “E”

(Figure 2).

3.Turn nut “E” clockwise 1/8 turn to tighten bevel lock

tension or turn counter-clockwise to 1/8 turn to

loosen bevel lock tension.

4.Push down bevel lock lever until you feel the lever

snap into the locked position.

5.Verify that bevel lock tension holds the bevel posi-

tion secure and also allows bevel lock lever to lock

down to the point that a solid stop is felt.

6.

If necessary

, repeat steps 1–5 to adjust the tension.

Figure 1. Left 45° Bevel Stop

Calibrating Left 45°

Bevel Stop

1. Remove rear cover to expose bolts.

2. Lift bevel lock lever to release bevel lock.

3. Tilt saw to 45° left bevel position.

4. Remove the ruler from the combination square

and position with 45° surface against blade.

(Figure 1)

5. Place 10mm open-end wrench on bolt head “F”.

While rotating bolt “F”, watch blade tilt movement

until it is aligned with the 45° surface on combina-

tion square. (Figure 2)

6. Adjust bevel pointer to 45° line on bevel scale.

F

E

Figure 2. Left 45° Bevel Adjustment