If heating, welding, or

cutting materials that are

galvanized, zinc plated, lead,

or cadmium plated refer to the General

Safety Information Section for

instructions. Extremely toxic fumes are

created when these metals are heated.

4 . Connect the work clamp to the

work piece. Make sure the contact is

on bare metal and not obstructed

by paint, varnish, corrosion, or non-

metallic materials.

5 . Insert the exposed part of the

electrode rod (the end with no flux)

into the jaws of the electrode

h o l d e r .

The electrode

holder and rod are

electrically “live” (current potential)

when the welder is on.

Grounding against

any metallic

surface may produce an arc which could

cause sparks and damage eyesight.

6 . Hold the electrode away from the

grounded work piece or

workbench. Turn on the welder to

either High or Low. Refer to the

following chart for proper output

s e t t i n g .

7 . Position the electrode to begin

weld, lower the welding helmet or

position the hand shield, and strike

an arc. Adjust output setting as

n e e d e d .

8 . When finished welding, turn welder

off and store properly.

4

Shielded Metal Arc Welder

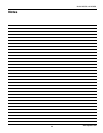

3 . To attach the handle, place shield on

a flat surface and press handle into

place (See Figure 5).

NOTE: If you have never welded before

or have little experience, a full face

helmet is recommended. Both hands

are needed to stabilize and control the

angle and arc length of the electrode.

O p e r a t i o n

1 . Be sure to read,

understand, and comply

with all precautions in

the General Safety

Information section. Be sure to read

the entire section entitled Welding

Guidelines prior to using this

e q u i p m e n t .

2 . Turn welder off and plug into

appropriate receptacle:

115v-15 amp - Low

115v-20 amp - High

3 . Verify that the surfaces of metals to

be joined are free from dirt, rust,

paint, oil, scale or other contaminants.

These contaminants make welding

difficult and cause poor welds.

All persons

operating this

equipment or in the area while

equipment is in use must wear protective

welding gear including: eye protection

with minimum shade 10 lens, flame

resistant clothing, leather welding

gloves, and full foot protection.

DUTY CYCLE / THERMOSTATIC

P R O T E C T I O N

Welder duty cycle is the percentage of

actual weld time that can occur in a

ten minute interval. For example, at a

10% duty cycle, actual welding can

occur for one minute, then the welder

must cool for nine minutes.

Internal components of this welder are

protected from overheating with an

automatic thermal switch. A yellow

lamp is illuminated on the front panel

if the duty cycle is exceeded. Welding

operations may continue when the

yellow lamp is no longer illuminated.

M a i n t e n a n c e

Disconnect power

supply and turn

machine off before inspecting or

servicing any components.

Before every use:

1 . Check condition of weld cables and

immediately repair or replace any

cables with damaged insulation.

2 . Check condition of power cord and

immediately repair or replace any

cord if damaged.

3 . Check condition of electrode holder

insulating pieces and immediately

replace cracked or missing

insulators. Verify that all fasteners

are tight and insulated.

Do not operate this

welding machine

with cracked or missing insulation on

welding cables, electrode holder, or

power cord.

Every 3 months:

Replace any unreadable labels on the

welder. Use compressed air to blow all

dust and lint from the ventilation

o p e n i n g s .

w w w . c h p o w e r . c o m

Electrode Output

Diameter Setting

1/16 in. (1.6 mm) L o w

5/64 in. (2 mm) H i g h

Figure 5

Assembly ( C o n t i n u e d )