SKU 42933 For technical questions, please call 1-800-444-3353. Page 20

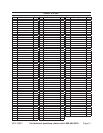

Troubleshooting

PROBLEM CAUSE SOLUTION

Saw will not make a square

crosscut or a good 60° mitre

cut.

Arm is not perpendicular to the rip fence1.

Too much play between the arm and column2.

Yoke too loose when clamped to carriage3.

Dust between stock and rip fence4.

Table is not parallel with arm5.

Rip Fence is not straight. 6.

Rear edge of table A not straight7.

Adjust the crosscut travel with the rip fence1.

Tighten the column sleeve bolt2.

Adjust Yoke clamp handle3.

Clean worktable4.

Adjust Table A5.

Replace rip fence.6.

Sand or replace Table A7.

60° cut not accurate Saw Blade not perpendicular to worktable1.

Too much play between arm and column2.

Yoke is too loose when clamped to carriage3.

Bevel Lock Knob is loose4.

Table is not parallel with arm5.

Adjust Saw Blade1.

Tighten column sleeve bolt2.

Adjust Yoke Clamp Handle3.

Adjust Bevel Lock Knob4.

Adjust Table A5.

Workpiece has a tendency

to walk away from the fence

when ripping

Saw Blade is not parallel with the fence. 1.

Arm is not perpendicular to the rip fence.2.

Adjust Saw Blade1.

Adjust cross cut travel with rip fence2.

Saw Blade tends to advance

over the stock too fast

Dull Saw Blade1.

Not pulling the Saw Blade properly2.

Replace or sharpen blade1.

Draw Saw Blade across stock with a slow 2.

and steady pull

Cut depth varies from one end

to the other

Too much play between the arm and column Tighten column sleeve bolt

Saw does not travel smoothly

in arm tracks

Dirty tracts1.

Bad Bearings2.

Clean tracts1.

Replace Bearings2.

Elevating Handle slips when

elevating or lowering the Saw

Blade

Screw loose on Elevating Handle Tighten Screw

Clamping knobs do not hold

motor assembly to the set

position(s)

Treads stripped on knob(s) Replace knob(s)

Saw Blade scores workpiece,

not giving a good nished cut

Saw Blade is leaning to one side1.

Too much play between arm and column2.

Yoke too loose when clamped to carriage3.

Saw Blade bent or dull4.

Not feeding saw properly 5.

Using improper Saw Blade for nish cut 6.

desired

Adjust Saw Blade square to rip fence1.

Tighten column sleeve bolt2.

Adjust Yoke Clamp Handle3.

Replace Saw Blade4.

Draw the Saw Blade across stock with a 5.

slow and steady pull

Replace Saw Blade6.

Saw Blade or dado blades

tend to push stock to one side

when cross-cutting

Saw Blade is heeling1.

Too much play between arm and column2.

Yoke too loose when clamped to carriage3.

Rip fence not straight4.

Dull Saw Blade5.

Adjust Saw Blade square to the rip fence1.

Tighten column sleeve bolt2.

Adjust Yoke Clamp Handle3.

Replace rip fence4.

Replace or sharpen Saw Blade5.

Saw Blade Stalls when ripping Arbor Nut loose1.

Dull Saw Blade2.

Saw Blade not parallel to fence3.

Tighten1.

Replace or sharpen2.

Adjust Saw Blade or fence to parallel3.

Motor will not reach full speed

or power

Faulty ON/OFF Switch 1.

Circuit overloaded with other appliances2.

Motor windings burned out3.

Circuit used is under rated for this 4.

application

Have the Switch unit checked by a qualied 1.

technician

Use a different circuit for the machine2.

Replace motor3.

Use a different circuit with sufcient power 4.

for this machine

Motor overheats, stalls, trips

the circuit breakers or fuses

Overloaded motor1.

Improper cooling caused by excessive 2.

sawdust accumulation around the motor

Motor winding burned out or open3.

Power source circuit breakers do not have 4.

sufcient power capacity

Feed stock into Saw Blade more slowly1.

Clean motor housing with compressed air 2.

Replace motor using a qualied technician3.

Install proper size circuit breakers or change 4.

circuits to one with more capacity