Page 17For technical questions, please call 1-800-444-3353.SKU 95136

SAFETYSERVICE OPERATIONTECHNIQUES SETUP

Troubleshooting (cont.)

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power and air before adjusting, cleaning, or

repairing the unit. A technician should discharge all capacitors before performing any internal procedures.

If the steps above do not solve the problem or if the repairs involved are too complex,

contact a qualied technician.

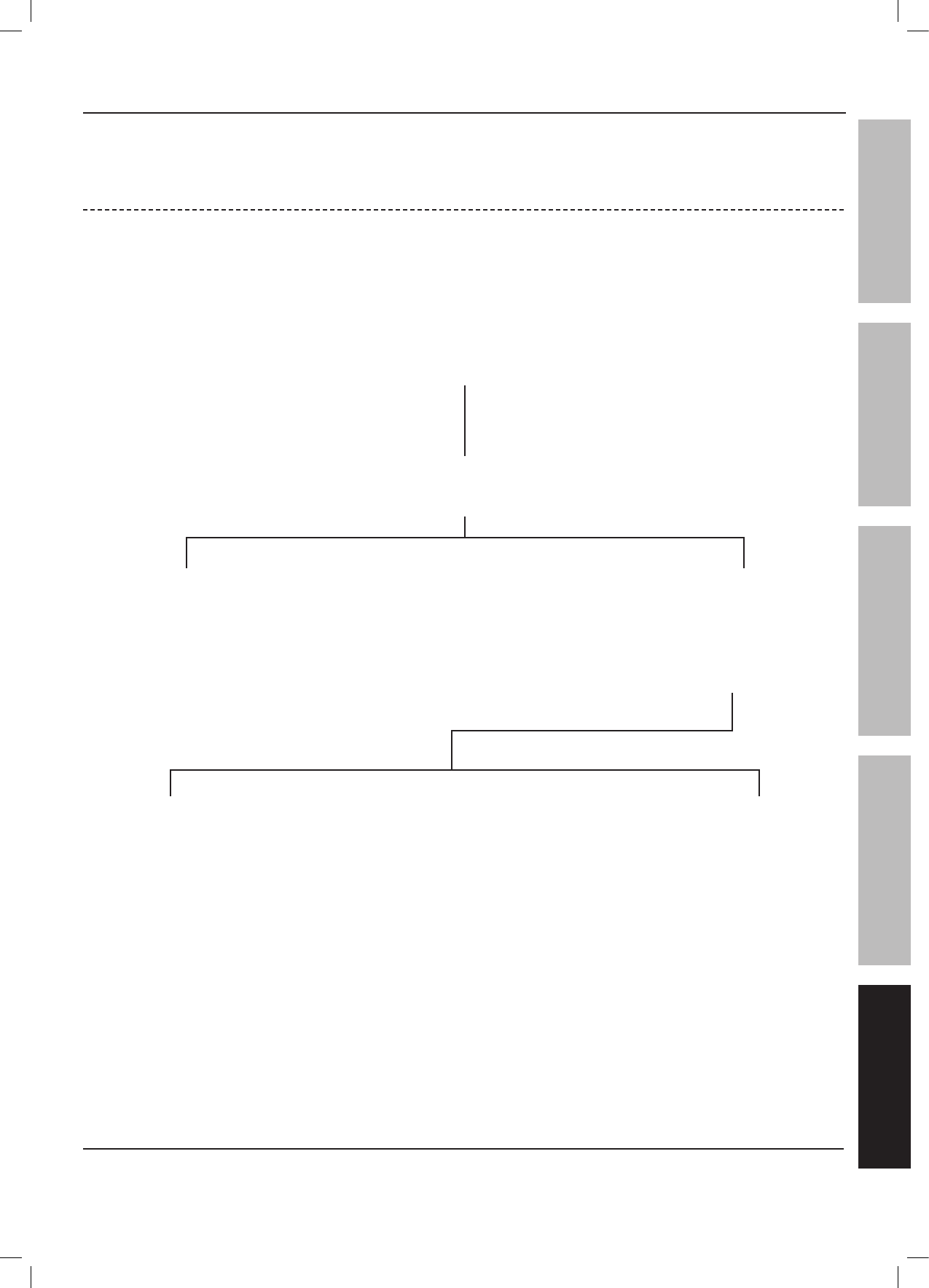

Amperage setting too high; cut at lowest

setting possible for the metal being cut.

FAST NOZZLE WEAR

OR

EXCESSIVE SLAG FORMATION

Take into account the thickness

and type of metal to be cut before

starting. Thinner materials

require lower amp settings.

PROBLEMS

REDUCED

Disconnect the Torch Cables.

Disassemble the torch assembly

and inspect all internal components,

as explained on page 11.

Replace any damaged or

missing components and

reassemble carefully, following

the directions on pages 6-11.

TORCH IN GOOD

CONDITION

DAMAGED

COMPONENTS FOUND

Air supply pressure may be inadequate:

a. Verify that the compressor is

delivering at least 3.5 CFM @ 80 PSI.

b. Set Regulator on the unit

to at least 60 PSI.

These two problems have similar causes

and will often appear simultaneously.

The same diagnostic procedures

and remedies apply to both.

PROBLEMS PERSIST AT

LOWEST PRACTICAL SETTING