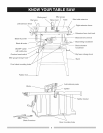

STORAGE (FIG. B=f, FiG. B-2)

Rip fence and miter gauge

1. Storage bracket for the rip fence (1) is located on the

right side of the stand.

2. Storage bracket for the miter gauge (2) is located on

the left side of the stand.

Fig. B-f

Fig. B-2

-2

MOUNTING SAW ONTO WORK SURFACE (FIG. C)

1. tf the leg set will not be used, the saw must be

properly secured to a sturdy workbench using the

four mounting holes at the base of the saw.

2. The surface of the table where the saw is to be

mounted must have a hole large enough to facilitate

sawdust fall-through and removal.

3. Square the saw on the mounting surface and mark

the location of the four 3/8 in. mounting holes (1).

4. Drill 3/8 in. hole into the mounting surface.

5. Mark an 11 in. square (2) centered between the four

mounting holes (1).

6. Cut out and remove the square.

7. This opening will allow sawdust to fall through the

saw base.

8. Place the saw on the work surface and align the

mounting holes of the saw with those drilled through

the surface.

9. Fasten the saw to the work surface.

[A WARNINGI

Do not operate this machine on the floor. This is

very dangerous and may cause serious injury.

Fig. C

SQUARE

CUTOUT _--

2

1

I,AWARNING!

Failure to provide the sawdust fall=through hole for

use of the saw when mounted to a work surface and

not the stand will cause sawdust to build up in the

motor area, which may result in fire or cause motor

damage.

KEEPING THE AREA CLEAN

1. Sawdust and wood chips that fall from under the

saw will accumulate on the floor.

2. Make it a practice to pick up and discard this dust

when you have completed cutting.

BLADE RAISING HANDWHEEL (FIG. D, E)

1. Attach the up-down handwheel (1) to the elevation

rod (2) at the front of the saw. Make sure the slots (3)

in the hub of the handwheel (1) engage with the

pins (4).

2. Attach and tighten the dome nut (5 - Fig. E).

Fig. D

1

BLADE TILTING HANDWHEEL (FIG. E)

1. Attach the bevel 0° - 45° handwheel (6) to the blade

tilting rod on the right side of the saw in the same

manner as above.

2. Attach and tighten the handwheel dome nut (5).

Fig. E

11