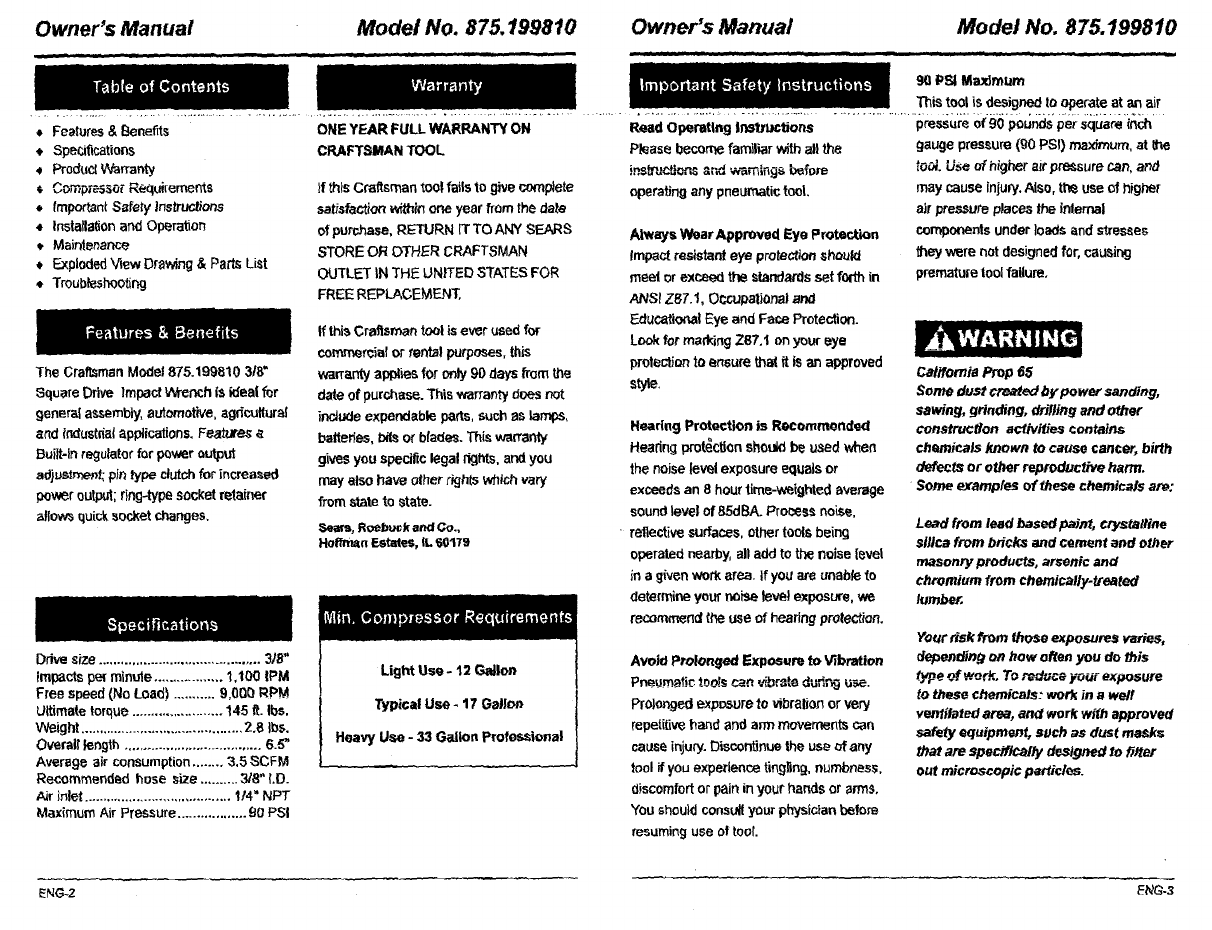

Owner's Manual Model No. 875.199810 Owner's Manual Model No. 875.199810

• Features & Benefits

SpeCifications

,_ Product W'arranty

Oomp_so{ Requirements

• important Safety Instructions

• Installation and Operation

Maintenance

+ Exploded View Drawing & Parts List

• Troubleshooting

ONE YEAR FULL WARRANTY ON

CRAFTSMAN TOOL

}f this Cfa_:sman tool fails to give complete

satisfaction _in one year from the dale

of purchase, RETURN IT TO ANY SEARS

STORE OR OTHER cRAFTSMAN

OUTLET IN THE UNITED STATES FOR

FREE REPLACEMEN£

The Craftsman Model 875.199810 3/8"

Square Drive Impact Wrench is ideal for

general assembly, automotive, ag_culfur_d

and lndustda_applications. Features ,_

Built-in regulator for power Q_utput

ad}ustmen_;pJr_type clutc_hfor increased

power output;ring_/pe socket retainer

aflow_ quick socket changes,

ffthis Craftsman tool is ever used for

commerciaf or renal purples, this

warranty applies for orgy90 days from the

date of purchase. This warranty does not

include expendable parts, such as lamps,

batteries, _ or blades. This warranty

gives you specific legal _Jhts. and you

may also have other rights which vary

from state to state.

,,_ws, Roebuck andCo.,

Hotfn_n Estates, _. S017e

Drive s_ze........................................... 318"

Impacts per minute .................. 1,100 IPM

Free speed (No Load) ........... 9,000 RPM

Ultimate torque ........................ 145 it. Ibs,

Weight ........................................... 2.8 Ibs.

Ovefali' h_ngth.................................... 6.5 _

Average air consumption ........ 3,5 SCFM

Recommended hose size .......... 3/8" f.D.

Air inlet ....................................... I!4" NPT

Maximum Air Pressure .................. fl0 PSI

Light Use- 12 Gatlo_

Typical Use. 17 Ga|lon

Heavy Use - 33 Gallon Profee_|onal

Read Operating In_0'l_ctions

Please becon_ familiar with all the

insP=_Jo,",s a_'_ _,-a_Ings b_fore

operating any pneumatic toot,

AlwaysWearApproved EyeProt_,tion

Impactresistanteyeprotectionshould

meetor exceedthestandarcissetforth in

ANS!ZBT.1,Occupationaland

EducationalEye andFaceProtection.

LookformaWjngZ87,1 onyoureye

protectionto ensure_at ft is an approved

style.

Hearieg Protection is Recommended

Heanng protection shouk_be used when

the noise level exposure equals or

exceeds an 8 hour time-weighted average

sound level of 85dBA. Process noise,

reflective surfaces, other tools being

operated nearby, all add tothe noise [eve|

Jna given wo_ area_ ifyou a_e unable to

determine your noise _evetexposure, we

recom,-_d the use of hearing pretect'_n.

Avoid Prolonged Exposure to Vibration

Pneum__ticto_s can vibrate dudng _se.

Prolonged e_posure to uCbralionor very

repetitivehand and arm movements can

cause injuq/. Discontinue the use of any

tool ifyou experience tingling, numbness,

discomfort or pain in your hands or arms,

You should consult your physician before

resuming use oftool.

90 PSi M_mum

This tool is designed to operate at an air

pressure of90 pounds per square inch

gauge pressure (90 PSI) maximum, at the

toG. U_e of higher air pre_sure can, and

may cause injuPj. Also, tt_ use _f higher

air pressure places the internal

components under loads and stresses

they were net designed for,causing

premature tool failure.

C,zdifomia Prop 65

Some du_t crea_ed by power sanding,

sawing, grinding, drilling and o_er

construction activities contains

chemicals known to cause cancer, birth

defects or other reproduc_ve harm.

Some examples of these chemicals are:

Lead from lead based paim, crystalline

silica from bricks and cement and other

masonry products, arsenic an_l

ch_mium from chemically-treated

lumber.

Your risk from those exposures varies,

depending on how often you do this

type of worP..To t_duce your exposure

to these chemicals: work in a welt

veedilated area, at_i work wfth approved

safety equipment, such as dust masks

that are SpeciftcJ41y designed to filter

out microscopic p_rticles.

ENG~2 _NG-3