Owner's Manual Model No. 875.199810 Owner's Manual

,=, ..m , ,

Model No. 875.199810

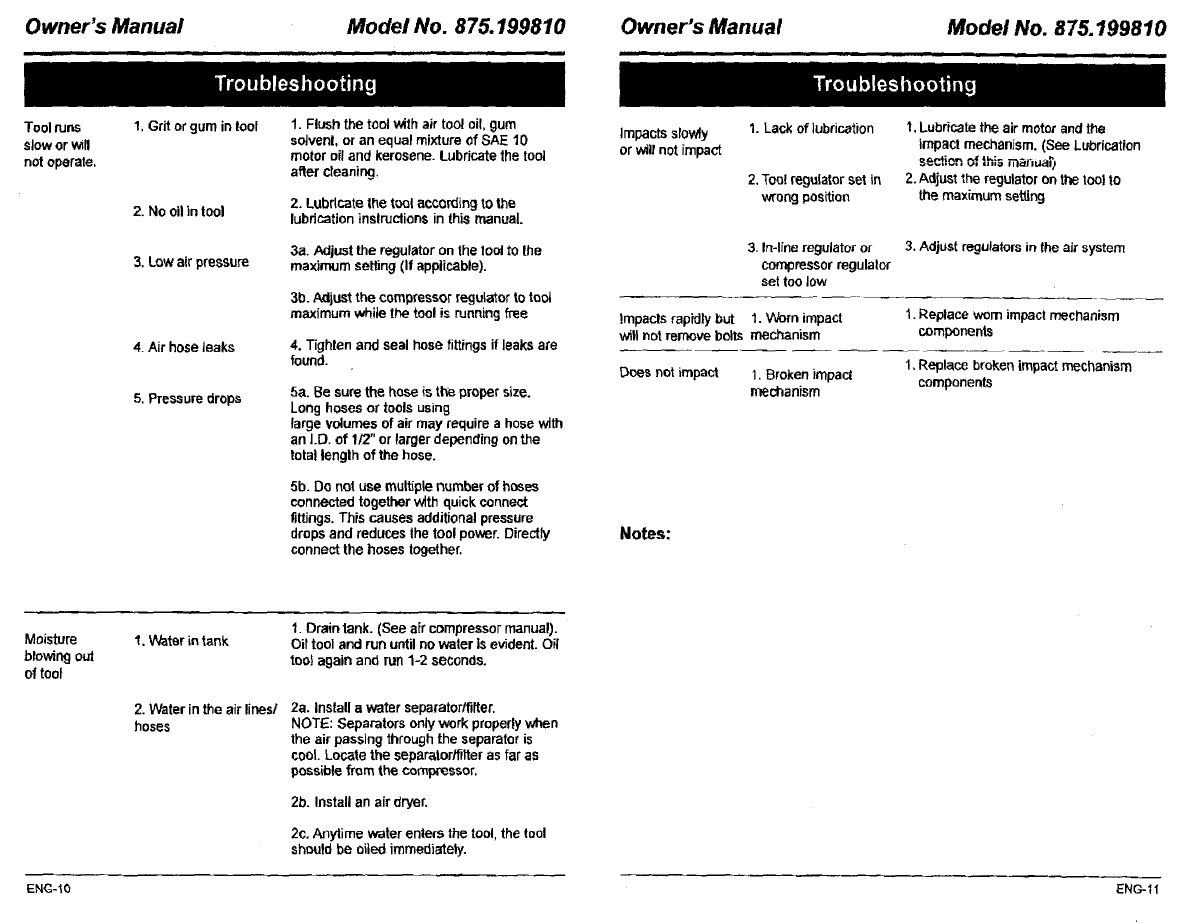

Toolruns

sloworv_ll

notoperate.

!. Grit or gum in tool

2. No oil in tool

3, Low air pressure

4. Air hose leaks

5. Pressure drops

1. Flush the tool with air tool oil, gum

solvent, or an equal mixture of SAE 10

motor oil and kerosene. Lubricate the tool

after cleaning.

2, Lubricate the tool according tO the

lubrication inslruclions in this manual.

3a. Adjust the regulator on the lool to the

maximum setting (If applicable).

3b. Adjust the compressor regulator totool

maximum while the tool is running free

4. Tighten and seal hose fittings if leaks m'e

found.

5a. Be sure the hose is the proper size.

Long hoses or tools using

large volumes ofair may require a hose with

an I.D. of 1/2" or larger depending on the

total lenglh of the hose.

5b. Do not use multiple number of hoses

connected together with quick connect

fittings. This causes additional pressure

drops and reduces the tool power. Directly

connect the hoses together.

Impactssrowiy

orwiltnotimpact

1. Lack of lubrication

2,Tool regulator set in

wrong position

I. Lubricate the air motor and the

impact mechanism. (See Lubrication

sectionof this n-_uaT_

2.Adjust the regulator on the tool to

the maximum setting

3. In-line regulator or 3. Adjust regulators in the air system

compressor regulalor

set too low

lmpacls rapidly but 1. Worn impact

will notremove bolts mechanism

Does not impact 1. Broken impact

mechanism

1.Replace worn impact mechanism

components

1, Replace broken impact mechanism

components

Notes:

Mois_re

browing out

of toot

1. V_ter in tank

1. Drain tank. (See air compressor manual).

Oil tool and run until no water Is evident. Oil

too}again and run 1-2 seconds.

2. Water in the air lines/

hoses

2a. Install a water separator/fitter.

NOTE: Separators only work properly when

the air passing through the separator is

cool. Locate the separator/filter as far as

possible from the compressor.

2b. Install an air dryer,

2c, Anytime water enters the tool, the tool

should be oiled immediately.

ENG-10 ENG-_I