Owner's Manual Model No. 875.199810 Owner's Manual Model No. 875.199810

Lubdcatien

An in-linefilter-regulator-lubricator (fig 1)

isrecommended as itincreases tool life

ar_l keeps the tool insustained operation.

The in-line lubdcalor should be mgulady

checked and tiffedwith air loot oar.Proper

adjustment ofthe ir_line lubltcator is

performed by placing asheet of paper

next to the tools exhaust ports and holding

the throttleopen approxfmateiy 30

seconds. The lubricator is properly set

when alight stain of oilCOfleCISon Ihe

paper.

Excessive amounts ofoil should be

avoided, fnthe event that it becomes

necessary to store the tool for an

extended period of time (overnight,

weekend, etc.), itshould receive a

generous amount oflubrication through

the airinlet (Figure 3).The tool should be

runfor aptxoximatoly 30 seconds to

ensure oilhasbeen everdy distributed

throughout thetool The tool should be

stored in a clean and dryenvironment.

Recommended Lubricants

Use air leo; oi!or any other high grade

turbine ogco_ltainingmoisture absorbent,

rust inh_itors, metal _et_ng agents and

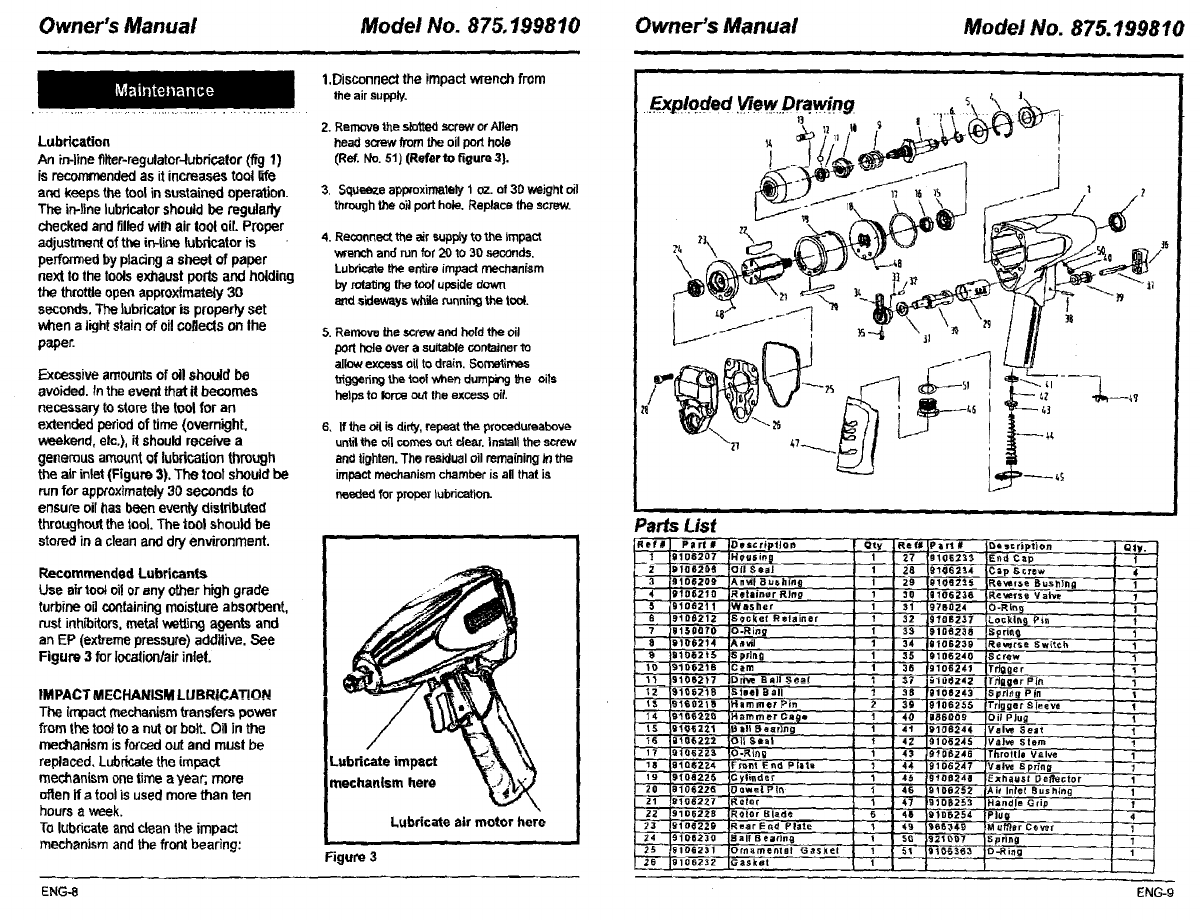

an EP (extreme pressure) addllive. See

Figure 3 for lecalion/air inleL

IMPACT MECHANISM LUBRICATION

The impact mechanism transfers power

from the toottoa nut or bolt. Oil inthe

mechanism isforced out and must be

replaced. Lubricate the impact

mechanism onetime ayear, more

often If a tool isused more than ten

hours a week.

To lub_qcateand clean the impact

mechanism and the front bearing:

1.Disconnect the impact wrench from

theairsupply.

2. RRnlOvo the siol;ted screw or Allen

head screw from the oil port hole

(Ref, No. 51) (Refer to figure 3}.

3, Squeeze app_oxirrm.tely 1 oz. of 30 weight oil

through the oil port hole. Replace the screw.

4. Reconnectthe airsupplyto theimpact

wrenchandrunfor201o30 seconds.

Luixicate the entireimpactmechanism

byrotatingthetoolupsidedovm

endsidewayswh_ runningthetool

5. Remove the screw and held the oil

port hole over a suitable container to

allow excess oil to drain. S_n",etim'a,s

_ggefin9 the toof when dur_pang _e oils

helps to lone out the excess oil

6. If the oil is di_3', repeat the procedureabove

until the oil comes out de_'. Install the screw

and tighten. The residual oil remaining _ the

impact mechanism chamber is aftthat is

needed for proper lubrication.

Lubricate impact

mechanism here

Lubricate air motor here

Figure 3

3

4

B.

7

S

_2

_4

15"

t6

t_

18

20 :8i0S2ZS 3e,el Pin

21 tt1062_7 _otor

22 9105229 _oiOr Blade

23 910d22g _ear E_d Plate

24 910B230 gall B e a.-ing

2'_; 9106231 !(_rn_me_t nl Gasket

26 9106232 Gasket

Parts List

Sef# Plrt#

9108207

91052_9

9!0620_

91D6210

_1062tl

9t06212

91_0070

_106214

91082i_

SIO_21S

910S217

916S21_

91_$22_

9105221

gt06_22

9106223

9106,2Z4

9108226

I_ sc ription Qty.

End Cap i

_ap ectew 4

P.e_e_s _ VaF/e 1

3-Rin 9 ]

iLo_kln_ F'in I -

_¢rew

ri_oer

'Trigger,P n "_

_prl_g Pin _--

Trig ge t _ leeve f --

Oil PJug 1

Val_ Seat -- 1

Val'_ Stem

Ti_rot tie Ve.lve

Valve Spring

Exhaust DeRector 1

46 9106262 Air Inlet Bushing - 1

1 _'7 9106253 H==ndle Grip

1 4_1 _6.6._149 M uft}er COV_'_ 1

t 50 S21_7 Sprtn 9 1

IDBscrIptlo;') I;tty Ref# Part #_

IH O'Je;in_l -- 1 27 g10S2_$

(311 Seal 1 26 gI _162"_.4

[A nv]l' _ us hins | 2T 910g2_

_etainer RIng 1 30 ].106236

A/asher 1 31 976024

G¢c_et Retainer 1 32 9?06237

_-Ring 1 33 9106236

_t_J 1 34 9108239

5 pFltl9 1 35 9106240

3am 1 38 9106241

IDd_ e =tll-_@a! I 37 -_1Q_Z42'

_.teel B;all ? 38 91-08243

4immer Pin -- _' 3_ 9106'255

H_mmer_a_. 1 40 gBgG'0g

Bill Bearing .. t 41 9106244

311 Sea| _ 42 9106245

_O.-R t0 g i 43 9_ 0S248

Fr_,_t Fnd Piat_ I 44 9106247'

._y|i_d s_" '1 45 gf0s241

ENG-8 ENG-g