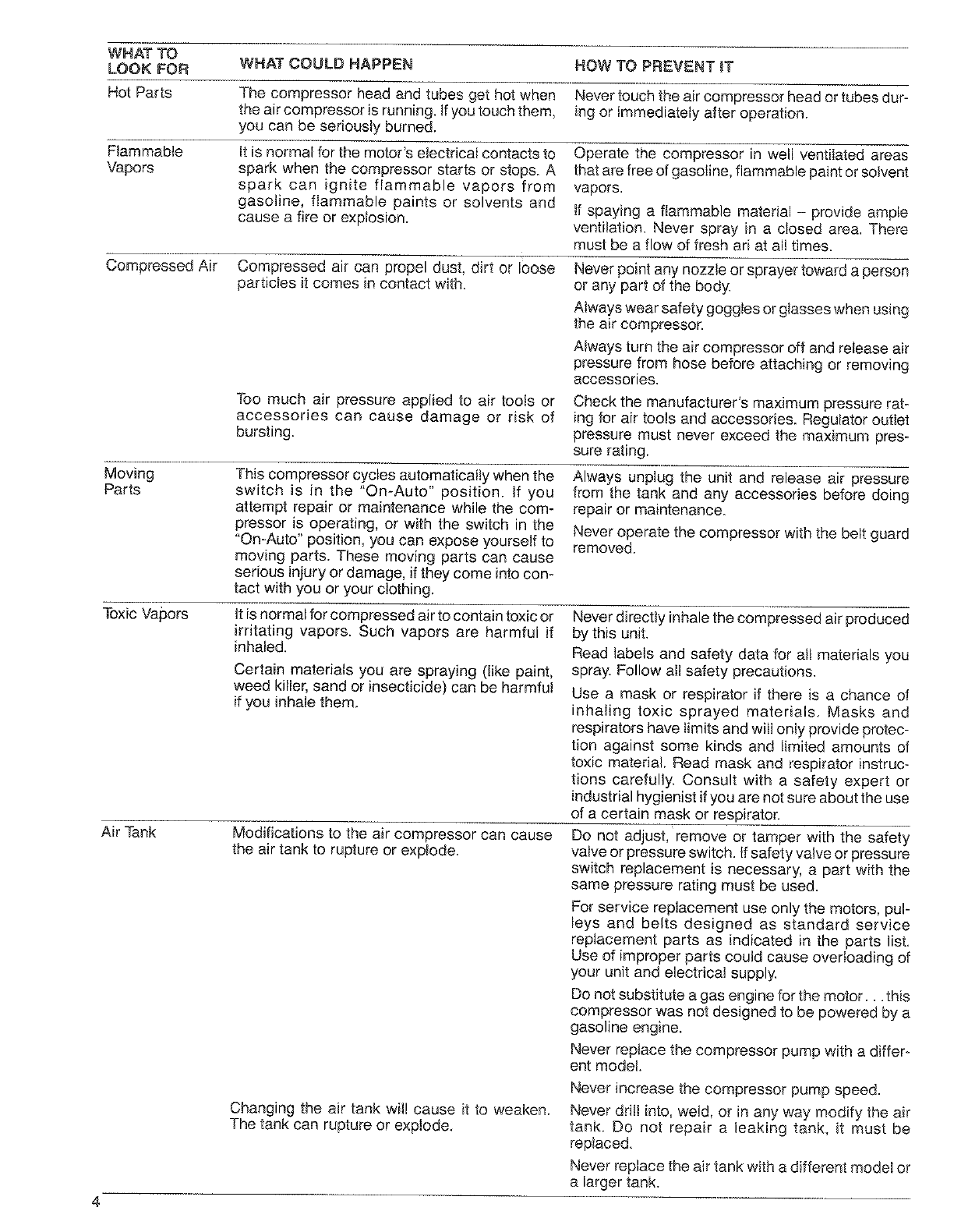

WHATTO

LOOK FOR WHAT COULD HAPPEN NOW TO PREVENT }T

Hot Parts The compressor head and tubes get hot when Never touch the air compressor head or tubes dar-

the air compressor is running. If you touch them, ing or immediately after operation.

you can be seriously burned.

Flammable It is normal for the motor's electrical contacts to Operate the compressor in well ventiIated areas

Vapors spark when the compressor starts or stops. A thatarefreeofgasotine, flammablepaintorsoivent

spark can ignite flammable vapors from vapors.

gasoline, flammable paints or solvents and if spaying a flammable material - provide ample

cause a fire or explosion.

ventilation. Never spray in a closed area. There

must be a flow of fresh ad at alt times.

Compressed Air Compressed air can propel dust, dirt or loose Never point any nozzle or sprayer toward a person

particles it comes in contact with. or any part of the body.

Always wear safety goggles or glasses when using

the air compressor.

Always turn the air compressor off and release air

pressure from hose before attaching or removing

accessories.

Moving

Parts

Toxic 'Vapors

Air Tank

Too much air pressure applied to air tools or

accessories can cause damage or risk of

bursting.

This compressor cycles automatically when the

switch is in the "On-Auto" position. If you

attempt repair or maintenance while the com-

pressor is operating, or with the switch in the

"On-Auto" position, you can expose yourself to

moving parts. These moving parts can cause

serious injury or damage, if they come into con-

tact with you or your clothing.

Check the manufacturer's maximum pressure rat-

ing for air tools and accessories. Regulator outiet

pressure must never exceed the maximum pres-

sure rating.

It is normal for compressed air to contain toxic or

irritating vapors. Such vapors are harmful if

inhaled.

Always unplug the unit and release air pressure

from the tank and any accessories before doing

repair or maintenance.

Never operate the compressor with the belt guard

removed.

Certain materials you are spraying (like paint,

weed killer, sand or insecticide) can be harmfu!

if you inhale them.

Modifications to the air compressor can cause

the air tank to rupture or explode.

Changing the air tank wi!! cause it to weaken.

The tank can rupture or exptode.

Never directly inhale the compressed air produced

by this unit.

Read labels and safety data for all materials you

spray. Follow alI safety precautions.

Use a mask or respirator if there is a chance of

inhating toxic sprayed materials. Masks and

respirators have timits and will only provide protec-

tion against some kinds and limited amounts of

toxic material. Read mask and respirator instruc-

tions carefully. Consult with a safety expert or

industrial hygienist if you are not sure about the use

of a certain mask or respirator.

Do not adjust, remove or tamper with the safety

vatve or pressure switch. If safety valve or pressure

switch replacement is necessary, a part with the

same pressure rating must be used.

For service replacement use only the motors, pul-

leys and belts designed as standard service

replacement parts as indicated in the parts list.

Use of improper parts could cause overloading of

your unit and electrical supply.

Do not substitute a gas engine for the motor.., this

compressor was not designed to be powered by a

gasoline engine.

Never replace the compressor pump with a differ_

ent model

Never increase the compressor pump speed.

Never drilt into, weld, or in any way modify the air

tank. Do not repair a leaking tank, it must be

replaced.

Never replace the air tank with a different model or

a larger tank.

4