-13-

Router Table for the Craftsman

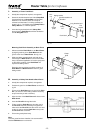

Fig. M

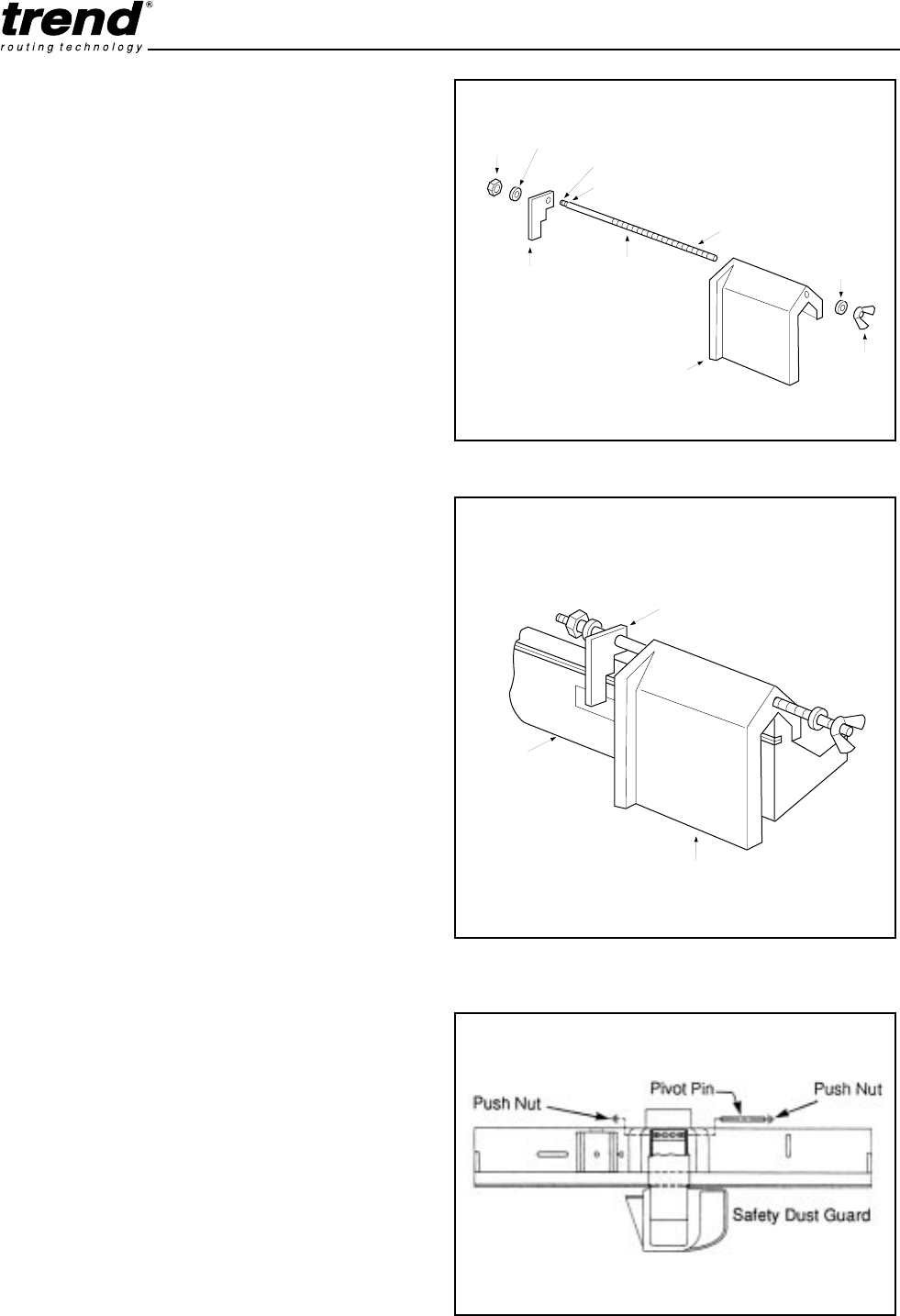

Fig. L.2

Fig. L.1

L.

Assembly of Tenon Push Block

1.

Identify the components required, see opposite.

2.

Screw the smaller threaded end of the Clamp Rod

into threaded hole in Clamp Plate until the plate

bottoms on it’s shoulder (make sure clamp is

oriented such that letter 'C' is facing outwards as

shown in fig. L.1) and

tightly secure Clamp Plate to

Clamp Rod with a 11mm AF spanner.

3.

Insert the longer threaded end of Clamp Rod

through hole in Push Block and fit the flat washer

and the Wing Nut onto it.

Mounting Push Block Assembly on Back Fence

1.

Mount assembled Push Block on the Back Fence

by aligning retaining rib on Push Block with the

groove in the face of Back Fence. See fig. L.2.

2.

Slide push block assembly back and forth along

entire length of Back Fence to ensure that it slides

freely. Occasional application of furniture spray wax

on the sliding surfaces of the Push Block will

improve the sliding motion.

Removing dust and chips from sliding surfaces of

Push Block and Back Fence will ensure a good

sliding motion.

M.

Assembly of Safety Dust Guard to Back Fence

1.

Identify the components required, see opposite.

2.

Position the guard on the Back Fence as shown in

fig. M.

3.

Fit one of the Push Nuts onto one end of the Pivot

Pin. (To ensure a secure fitting it will be necessary

to tap it onto the pin with a hammer).

4.

Align the holes in the Back Fence with those on the

Dust Guard.

5.

Insert the Pivot Pin through the holes.

6.

Fit the remaining Push Nut onto the other end of

the Pivot Pin. It will be necessary to support the

other end of the Pivot Pin onto the corner of a hard

surface in order to tap the Push Nut securely onto

the Pivot Pin with a hammer.

7.

Ensure the guard pivots freely.

Note

Once the guard has been installed, it is recommended

that the Push Nuts are not removed.

Hex

nut

Spring washer

Wing

nut

Flat

washer

Push block

Small threaded end

Long threaded end

Clamp

rod

Shoulder

Clamp

plate

Push block

Clamp

plate

Face of

back fence