23

CUTTING CURVES

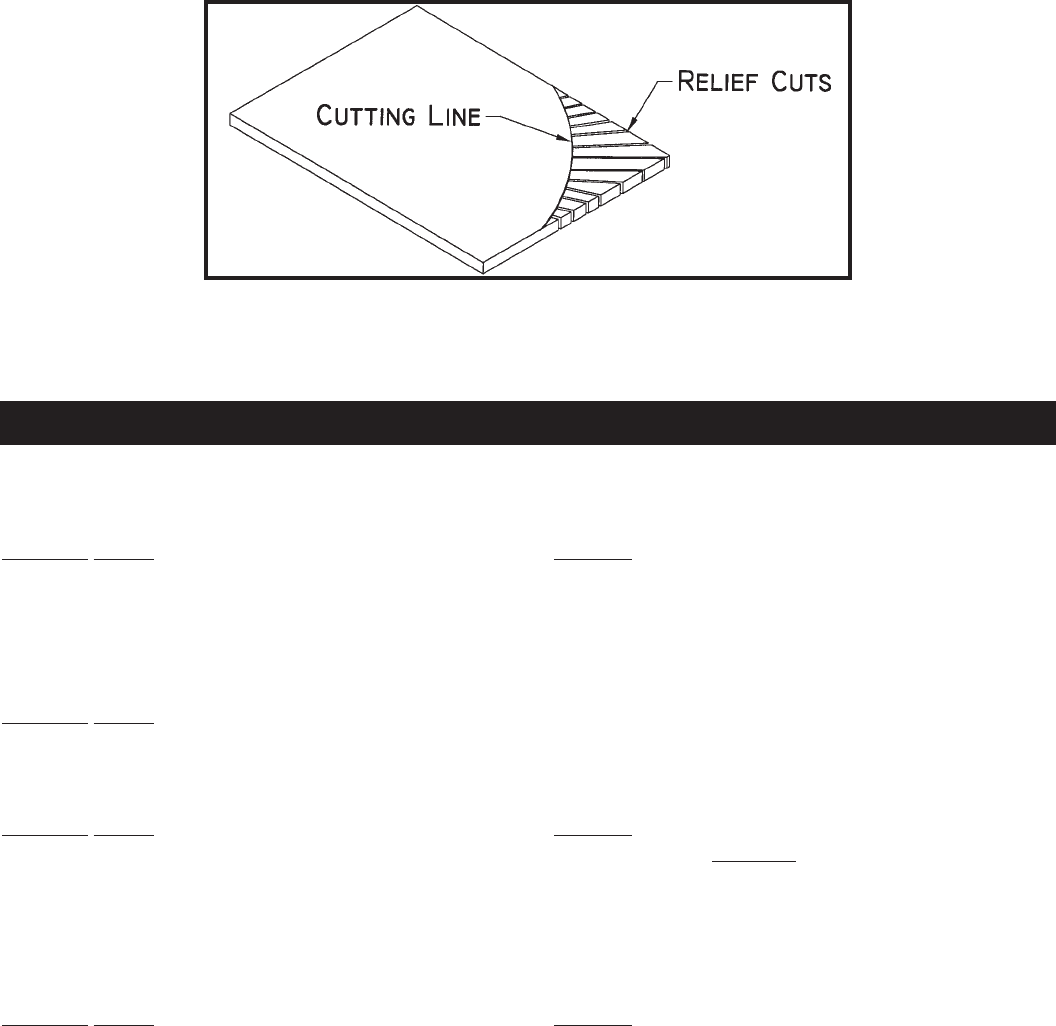

When cutting curves, turn the stock carefully so that the blade follows without twisting. If a curve is so abrupt that it is

necessary to repeatedly back up and cut a new kerf, a narrower blade, a blade with more set, or additional relief cuts

Fig. 61, may be necessary to allow the blade to cut more efficiently. The more set a blade has, the easier it will allow

the stock to be turned, but the cut is usually rougher.

When withdrawing the piece being cut, changing the cut, or for any other reason, be careful not to accidentally draw

the blade off the wheels. In most cases, it is easier and safer to turn the stock and saw out through the waste material,

rather than try to withdraw the stock from the blade.

Fig. 61

TROUBLESHOOTING GUIDE

(continued on next page)

In spite of how well a band saw is maintained, problems can occur. The following troubleshooting

guide will help you solve the more common problems:

Trouble: SAW WILL NOT START.

Pr

obable Cause Remedy

1. Saw not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker.

3. Cord damaged. 3. Replace cord.

Trouble: SAW WILL RUN, BUT BLADE WILL NOT TURN.

Probable Cause

1. Gearbox is disengaged. 1. Properly engage the shifter knob.

Trouble: BREAKER KICKS OUT FREQUENTLY.

Probable Cause Remedy

1. Extension cord too light or too long. 1. Replace with adequate size cord.

2. Feeding stock too fast. 2. Feed stock more slowly.

3. Blade in poor condition (dull, warped, gummed). 3. Clean, sharpen, or replace blade.

4. Low voltage supply. 4. Contact an electrician.

Trouble: BAND SAW VIBRATES EXCESSIVELY.

Probable Cause Remedy

1. Machine not mounted securely to stand. 1. Tighten all mounting hardware.

2. Stand on uneven surface. 2. Reposition on flat level surface.

3. Worn belt. 3. Replace belt.

4. Pulley not aligned. 4. Adjust pulleys.

5. Motor not fastened securely. 5. Tighten all mounting hardware.