25

BAND SAW BLADES

A band saw blade is a delicate piece of steel that is subjected to tremendous strain. You can obtain long use from a

band saw blade if you use it properly. Be sure you use blades of the proper thickness, width, and temper for the various

types of material and cuts.

Always use the widest blade possible. Use narrow blades only for sawing small, abrupt curves and for fine, delicate

work. This will save blades and will produce better cuts. For cutting wood and similar materials, Delta offers blades in

widths of 1/8", 1/4", 3/8", 1/2" and 3/4". Delta also offers several 1/2" blades for metal cutting of different teeth per

inch configurations.

Any one of a number of conditions may cause a band saw blade to break. Blade breakage is, in some cases,

unavoidable, being the natural result of the peculiar stresses to which blades are subjected. Blades will break often

due to avoidable causes, such as the lack of care to the blade or the blade not being properly adjusted to the band

saw. The most common causes of blade breakage are:

(1) faulty alignments and adjustments of the guides.

(2) forcing or twisting a wide blade around a curve of short radius.

(3) feeding the work piece too fast into the blade.

(4) dullness of the teeth, or absence of sufficient set.

(5) improperly tensioned blade.

(6) top guide set too high above the work piece being cut.

(7) using a blade with a lumpy or improperly finished braze or weld.

(8) continuous running of the saw blade when not cutting.

Use blades that are 93½" in length on this machine.

Always use a sharp blade. Keep it free from gum and pitch. Clean frequently with a stiff fiber brush.

Narrow blades are used for cutting small circles or curves while the wider blades are best suited for straight cutting

such as ripping.

A new blade, in most cases, will perform better and last longer than a re-sharpened blade.

Ensure that the blade guides are adjusted properly.

Do not force or twist the blade around a curve or a very short radius.

Feed the workpiece through the blade at a consistent rate, allow the blade to do the cutting – do not feed the work

piece too fast. Do not apply excessive tension to the blade. Set the tension to the proper tension as shown on the

tension scale.

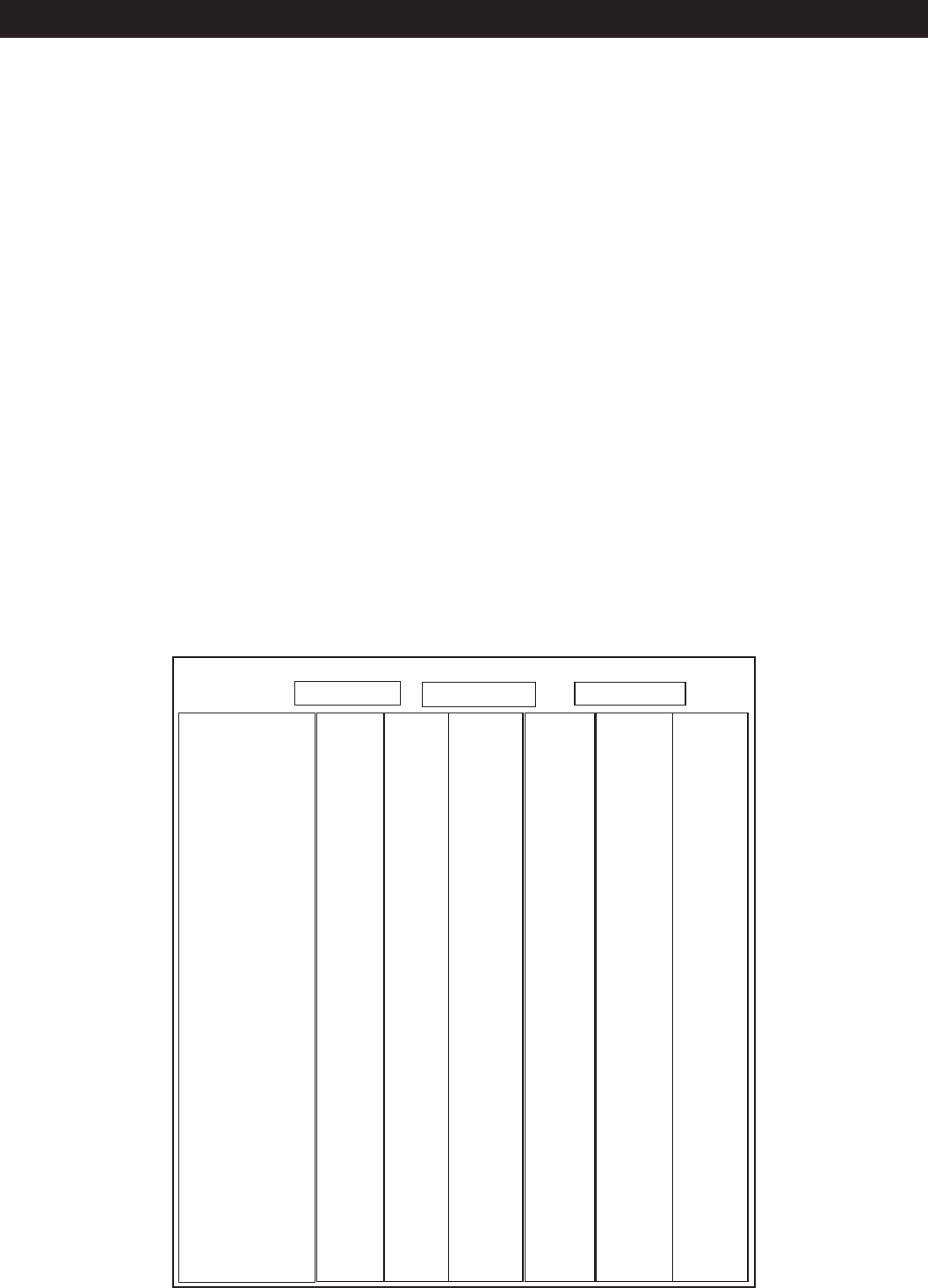

SUGGESTED METAL CUTTING BLADES AND SPEEDS

MATERIAL

STEELS

Angle Iron

Armor Plate

Carbon Steel

Chromium Steel

Cold Rolled Steel

Drill Rod

Graphite Steel

Hidfh speed Steel

Machinery Steel

Molybenium Steel

Nickel Steel

Silicon Manganese

Stainless Steel

Structural Steel

Tungsten Steel

FOUNDRY METALS

Brass-hard and soft

Bronze – Aluminum

Bronze – Manganese

Bronze _ Naval

Bronze – Phosphorus

Cast Iron – Gray

Cast Iron – Malleable

Cast Steel

Copper – Beryllium

Gunnite

Meehanite

Monet

Nickel – Cold Rolled

Nickel Silver

Silver

NON-METALS

Bakelite

Cork

Fibre

Hose –Canvas, Rubber

Hose – Mettalic

Mica

Plastics

Porcelain

Slate

Transite

TEETH

PER

INCH

24

18

24

24-18

24-18

14

18

24

18

18

18

18

24

24

18

18

18

18

18

18

18

18

18

18

24

18

18

14

18

24

10

10

14

10

24

24

14

24

24

24

FPM

160

40

85

85

220

85

60

85

160

85

40

85

40

160

40

335

335

160

160

335

115

160

160

160

335

160

115

60

220

220

335

3000

3000

3000

220

335

3000

160

335

335

TEETH

PER

INCH

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

18

14

14

10

14

18

10

10

10

18

14

18

18

18

FPM

160

40

60

60

220

60

40

60

160

60

40

85

40

160

40

335

335

115

115

335

85

115

115

85

220

115

85

40

220

220

220

3000

3000

220

3000

115

220

220

TEETH

PER

INCH

10

14

14

14

14

14

14

14

14

14

10

14

10

10

14

14

14

14

10

14

14

10

14

10

10

10

14

14

10

10

10

14

10

14

14

FPM

40

40

40

160

40

40

160

40

40

60

40

115

40

335

335

85

85

220

60

85

85

40

160

85

60

40

220

220

160

3000

3000

220

3000

160

85

UNDER ¼”

1/ TO ¾”

1“ANDUP

¼”