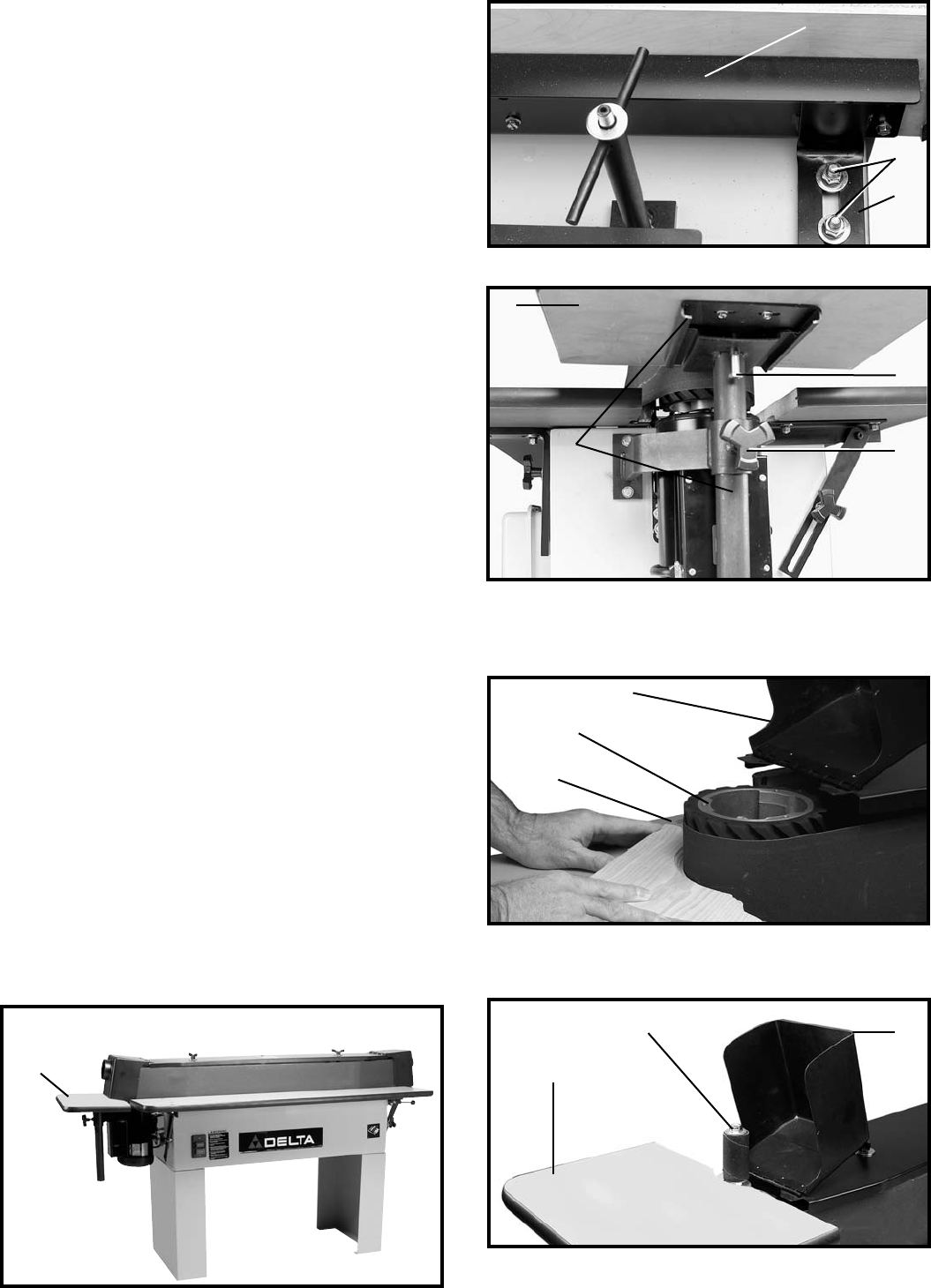

ADJUSTING LONG PLATEN

To adjust the long platen when sanding on the straight

table:

1. DISCONNECT TOOL FROM POWER SOURCE.

2. Remove the top guard and dust chute assembly.

3. Loosen two hex nuts (A) Fig.29 holding brackets (B) at

each end of the machine, and move platen (C) in or out

as needed.

IMPORTANT: MAKE CERTAIN THE LONG STRAIGHT

PLATEN IS NOT MOVED TOO FAR FORWARD SO

THAT THE TABLE INTERFERES WITH THE SANDING

BELT.

ADJUSTING AUXILIARY END TABLE

The auxiliary end table can be adjusted both vertically

and horizontally to accommodate contour sanding

operations around the drive pulley and smaller diameter

sanding operations around the drum spindles. The end

table can easily be adjusted for use as an extra work

support.

1. DISCONNECT TOOL FROM POWER SOURCE.

2. To adjust the end table vertically, loosen lock knob (A)

Fig. 30, and move the table assembly (B) up or down as

necessary. Tighten lock knob (A) after adjustments are

made.

3. To adjust the table horizontally, loosen locking screw

(C) Fig. 30, and move table (D) in or out as necessary.

Tighten locking screw (C) after adjustments are made.

4. Fig.31 illustrates the auxiliary end table (D) in position

for contour sanding around the drive pulley (E).

IMPORTANT: The dust chute (G) must be in the up

position as shown.

5. Position the table (D) Fig. 31, as close as possible to

the drive pulley (E) without contacting the sanding belt.

6. Fig. 32 illustrates the auxiliary end table (D) pos-

itioned for contour sanding around the auxiliary abrasive

drum and spindle assembly (H). IMPORTANT: The dust

chute (G) must be in the up position as shown.

7. When not in use, the auxiliary end table (D) Fig. 33, can

be positioned at its lowest adjustment level at the end of

the machine as shown.

11

Fig. 29

Fig. 30

Fig. 31

Fig. 32

Fig. 33

C

A

B

D

C

B

A

G

H

D

D

D

E

G