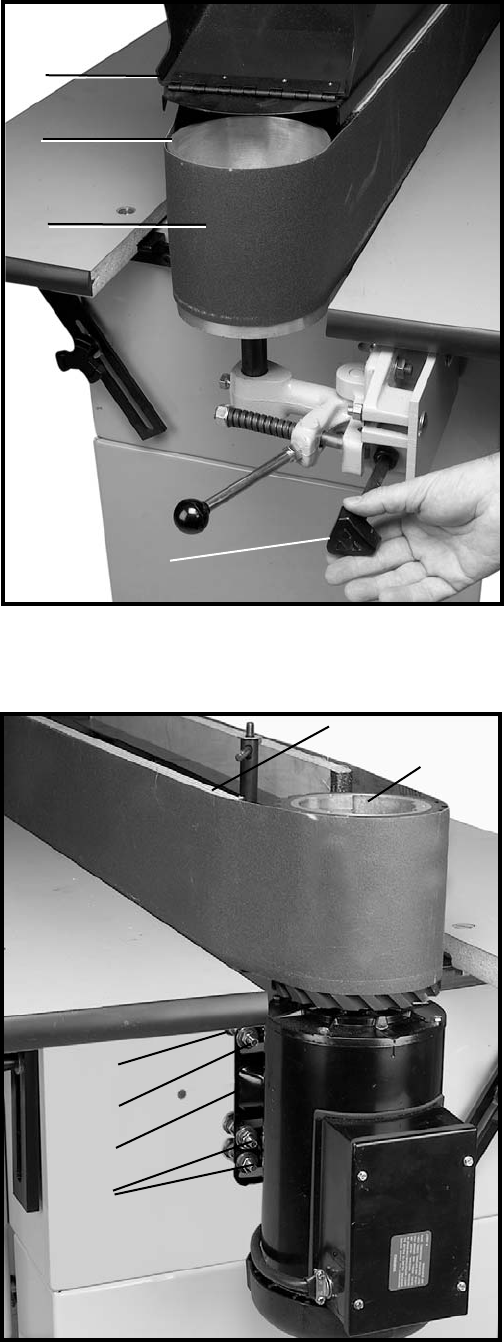

ADJUSTING BELT TRACKING

To check and adjust the tracking of the sanding belt on

the pulleys, proceed as follows:

1. Raise the dust chutes (A) Fig. 34, at both ends of the

top guard and dust chute assembly.

2. Make certain the top guard and dust chute assembly

is not interfering with the rotation of the sanding belt.

3. Apply power to the machine. Jog the on/off switch

several times and check to see if the sanding belt (B) Fig.

34, is tracking correctly on the pulleys, one of which is

shown at (C). If an adjustment is necessary, turn the

tracking knob (D) slightly right or left as needed until the

belt is tracking properly. NOTE: The belt tracking

adjustment can be made with the machine running

however, make certain the surface of the sanding belt is

freely moving and not in contact with any material or part

of the machine.

ADJUSTING PULLEY ALIGNMENT

The idler pulley and motor pulley have been aligned and

test run at the factory. However, rough handling during

shipment or drive pulley wear may cause the sanding

belt to run high or low at either the motor or idler end of

the machine. The top edge of the sanding belt (A) Fig. 35,

must be parallel to the top of the straight platen (B). If it

is not parallel, adjust as follows:

1. CAUTION: DISCONNECT TOOL FROM POWER

SOURCE.

2. NOTE: If the sanding belt (A) Fig. 35, is running LOW

on the motor pulley, this means the top of the motor is

too far away from the machine. The top of the motor

must be moved toward the machine by loosening the

two top INSIDE nuts, one of which is shown at (C), 1/2

turn and then tighten the two top outside nuts (D).

3. NOTE: If the sanding belt (A) Fig. 35, is running HIGH

on the motor pulley, this means the top of the motor is

too close to the machine. The top of the motor must be

moved away from the machine by loosening the two top

OUTSIDE nuts, one of which is shown at (D), 1/2 turn

and then tighten the two top inside nuts (C).

4. Apply power to the machine. Jog the on/off switch

several times and check to see if the top edge of the

sanding belt (A) Fig. 35, is running parallel to the top of

the straight platen (B). If further adjustment is necessary,

repeat the procedure.

CAUTION: DO NOT BEND THE MOTOR MOUNTING

PLATE (E) FIG. 35, WHEN MAKING THESE ADJUST-

MENTS. If the motor misalignment is excessive, it may

become necessary to move the bottom of the motor by

adjusting the lower motor mounting nuts (F), in or out, in

the same manner.

12

Fig. 34

Fig. 35

D

B

C

A

A

B

C

D

E

F