4

FOREWORD

Delta Model 40-570 16" Scroll Saw is designed to give high quality, smooth cutting performance with capacity to cut

up to 16" wide by 2" thick woodworking materials and has a 3/4" stroke. Delta Model 40-570 comes equipped with;

basic machine, integral dust port, variable speed 600-1650 spm, lock-out switch, cast iron table for minimal vibration,

Quickset II

®

Blade Chuck System for ergonomic “wrench-free” blade changing, threading and tensioning, accepts

wide variety of 5" flat end blades, 45° left tilting for bevel cuts, adjustable dust blower to keep cutting line free of dust.

UNPACKING AND CLEANING

Your new scroll saw is shipped completely assembled in the carton. Carefully unpack the saw and all loose items.

Remove the protective coating from the saw table surface. This coating may be removed with a soft cloth

moistened with kerosene (do not use acetone, gasoline or lacquer thinner for this purpose). After cleaning, cover

the table surface with a good quality paste wax. Buff out the wax thoroughly to prevent it from rubbing into your

workpieces.

CONNECTING SCROLL SAW TO POWER SOURCE

POWER CONNECTIONS

A separate electrical circuit should be used for your tools. This circuit should be protected with a fuse or circuit

breaker. Have a certified electrician replace or repair a worn cord immediately. Before connecting power, make sure

the switch is in the “LOCKED OFF” position and the electric current is of the same characteristics as stamped on the

nameplate. Running on low voltage will damage the motor.

WARNING: DO NOT EXPOSE THE TOOL TO RAIN OR OPERATE THE TOOL IN DAMP LOCATIONS.

MOTOR SPECIFICATIONS

Your scroll saw is wired for 110-120 volt, 60 HZ current. Before connecting the saw to the power source, make sure

the switch is in the “OFF” position.

0-6

0-6

0-6

0-6

120

120

120

120

up to 25

25-50

50-100

100-150

18 AWG

16 AWG

16 AWG

14 AWG

Ampere

Rating

Volts

Total Length of

Cord in Feet

Gage of

Extension Cord

6-10

6-10

6-10

6-10

120

120

120

120

up to 25

25-50

50-100

100-150

18 AWG

16 AWG

14 AWG

12 AWG

10-12

10-12

10-12

10-12

120

120

120

120

up to 25

25-50

50-100

100-150

16 AWG

16 AWG

14 AWG

12 AWG

12-16

12-16

12-16

120

120

120

up to 25

25-50

14 AWG

12 AWG

GREATER THAN 50’ NOT RECOMMENDED

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

240

240

240

240

240

240

240

240

240

240

240

240

240

240

240

up to 50

50-100

100-200

200-300

up to 50

50-100

100-200

200-300

up to 50

50-100

100-200

200-300

up to 50

50-100

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

GREATER THAN 100’ NOT RECOMMENDED

MINIMUM GAUGE EXTENSION CORD

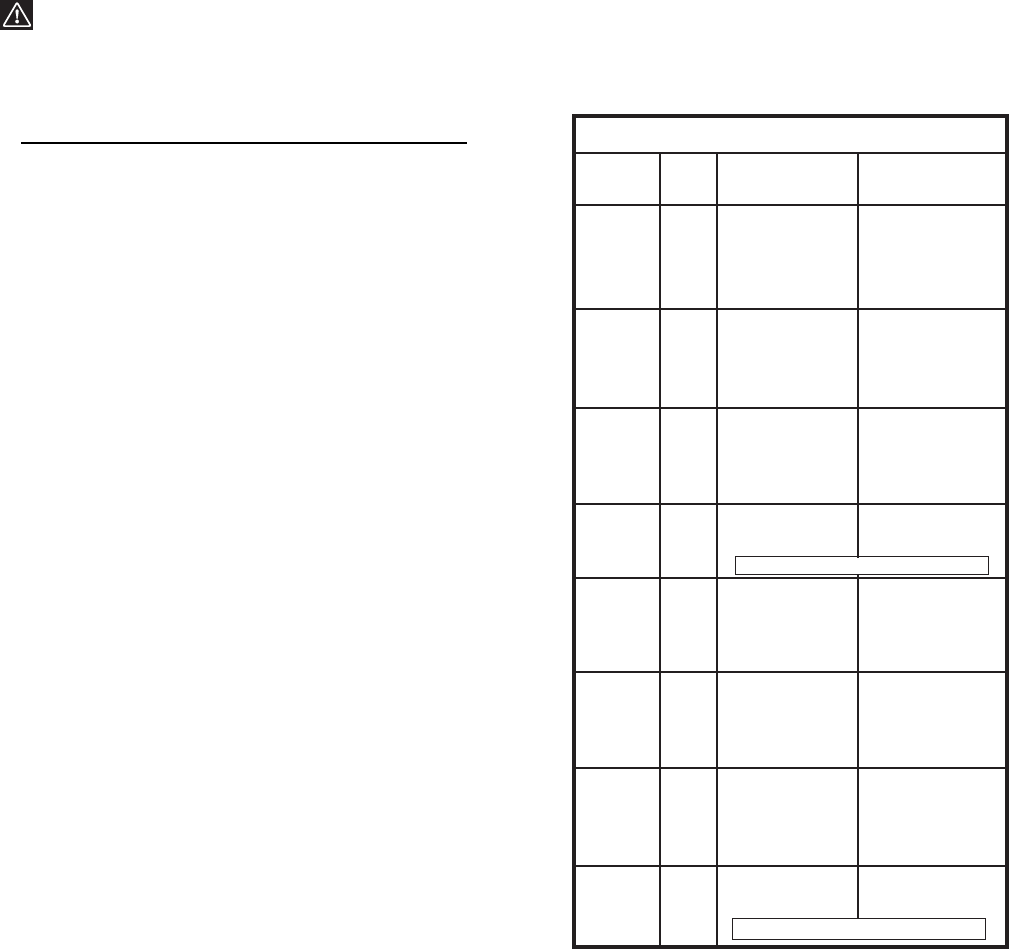

EXTENSION CORDS

Use proper extension cord. Make sure your extension

cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power

and overheating. Fig. 1 shows the correct size to use

depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

Fig. 1