9

SPUR AND LIVE CENTERS

To reduce the risk of injury, tighten all

screws and levers securely when adjusting any part

of the lathe.

To reduce the risk of injury, be sure

the taper on the spur center (G) is clean before

mounting to the headstock spindle.

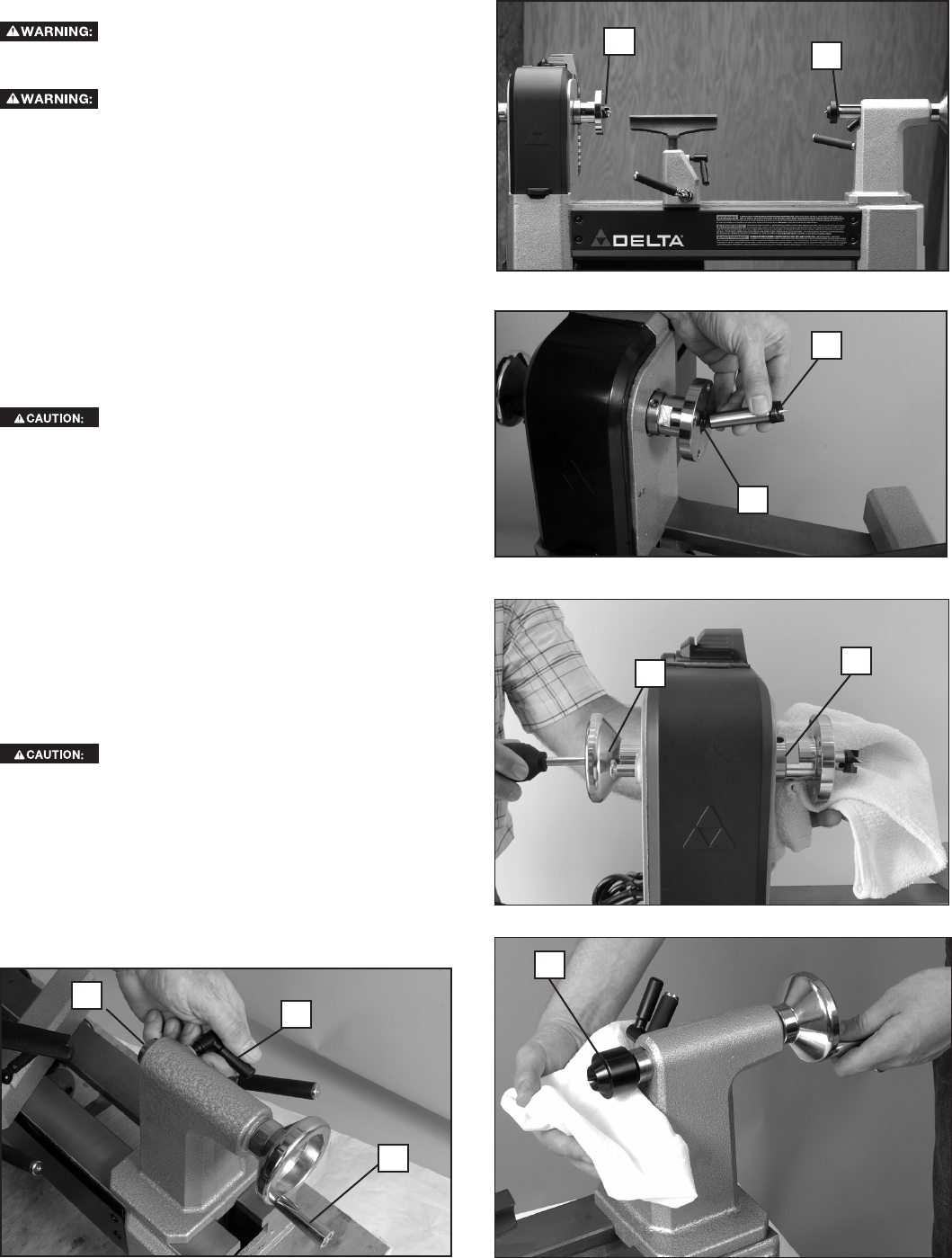

The spur center (G) Fig. 5 and live center (F) can be

used together (as shown in Fig. 5) to turn workpieces up

to 16-1/2" (419 mm) in length.

ATTACHING SPUR CENTER

Drive spur center into the workpiece using a soft mallet.

Then t spur center (G) Fig. 6 into the headstock spindle

bore (N) snugly.

NOTE: You do not need to remove the faceplate to attach

spur center.

REMOVING THE SPUR CENTER

To reduce the risk of injury, when

removing the centers, use a soft cloth to protect

against the sharp edge.

Insert knockout bar (H) Fig. 7 into spindle bore (as

shown in Fig. 7) and tap spur center (G) rmly to remove.

If necessary, tap knockout bar rmly with soft mallet.

NOTE: To avoid damage to spur center, be sure to hold

onto spur center as you tap it out.

ATTACHING LIVE CENTER

Loosen tailstock quill locking screw (O) Fig. 8. Turn

tailstock crank (P) clockwise three full turns to advance

the quill (Q). Then t the live center (F) Fig. 9 into the quill

snugly. The tailstock quill locking screw (O) Fig. 8 will be

tightened after you mount the workpiece.

REMOVING THE LIVE CENTER

To reduce the risk of injury, when

removing the centers, use a soft cloth to protect

against the sharp edge.

To eject the live center (F) Fig. 9, turn tailstock crank

(P) Fig. 8 counterclockwise to retract the quill. As quill

retracts, the live center contacts an internal ejecting pin.

When it does, you will feel the crank get harder to turn.

Turning further past this point loosens the live center for

easy removal.

Fig. 6

K

Fig. 5

G

F

G

H

Fig. 8

P

O

Q

Fig. 7

Fig. 9

H

F

G