12

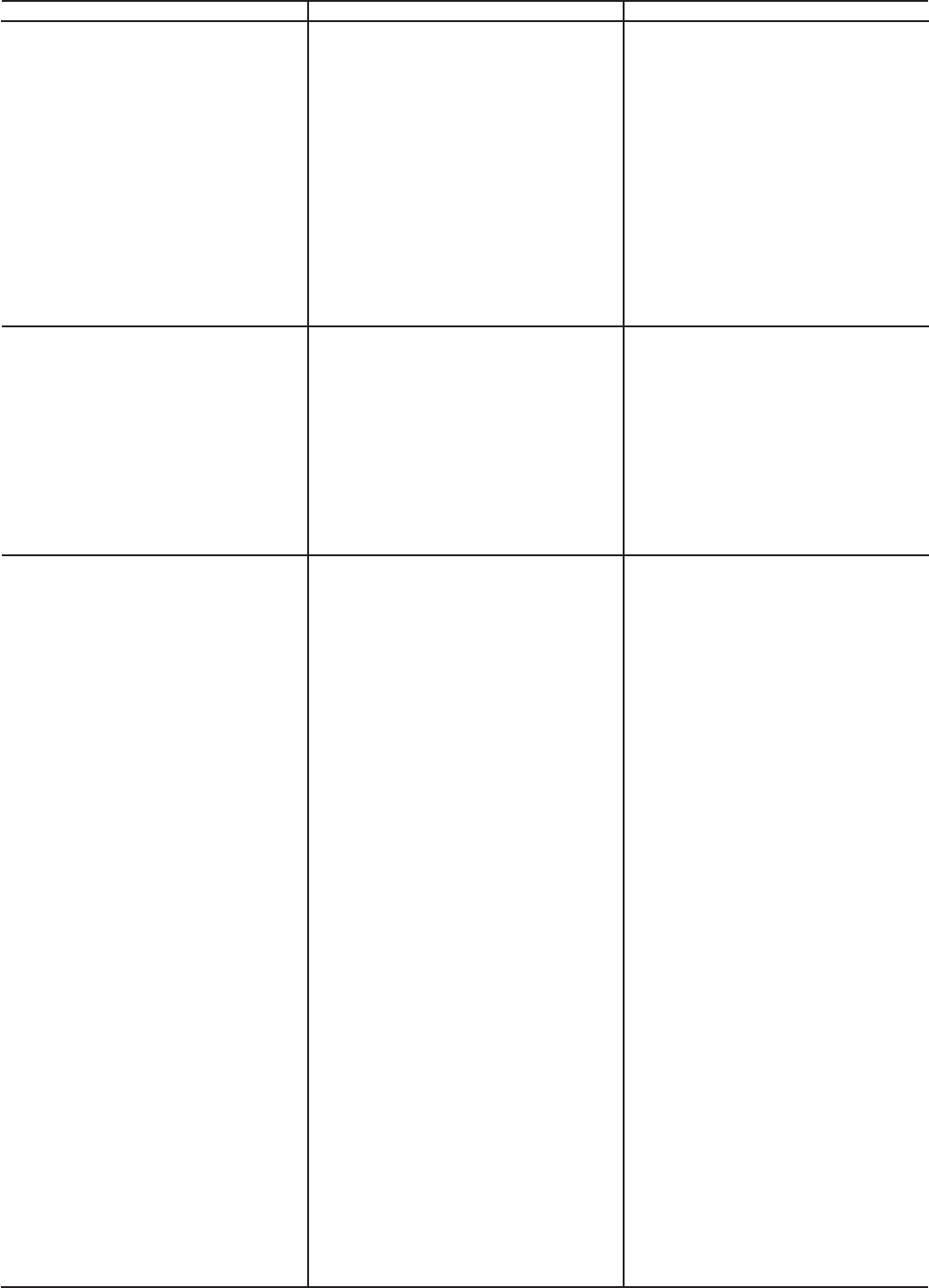

TROUBLESHOOTING GUIDE (CONT'D)

PROBLEM

Knocking noise

Motor will not run.

CAUSE

Restricted or defective check valve.

Loose pulley.

Low oil level.

Loose flywheel.

Loose compressor mounting screws.

Loose belt.

Belt too tight.

Carbon build-up.

Motor overload protection switch has

tripped.

Possible defective capacitor.

Possible defective motor.

Tank pressure exceeds pressure switch

"cut-in" pressure.

Check valve stuck open - fails to relieve

head pressure; motor cannot start.

Loose electrical connections.

Pressure release valve on pressure

switch has not unloaded head pressure.

Paint spray on internal motor parts.

Loose electrical connections.

Pressure release valve on pressure

switch has not unloaded head pressure.

Paint spray on internal motor parts.

CORRECTION

Remove and clean or replace.

Torque pulley set screw, see page 10.

Maintain prescribed oil level. Add oil.

Torque screw 15-20 ft. lbs.

Check screws. Torque as required (15-

20 ft.-lbs.)

Tighten wing nut until it contacts the

washer, plus one more turn.

Adjust belt tension (see "Belt Replace-

ment".)

Remove the head and valve plate. Clean

the valve plate and top of the piston. (Be

sure carbon does not fall into the cylin-

der.) Reassemble to 25-30 ft. lbs. using

new gasket and torque screws.

Let the motor cool off and reset switch

by pressing the red button located on

the end of the motor. If the overload still

trips, check for defective capacitor.

Return to Service Center for inspection

or replacement if necessary.

Have checked at a local Authorized

Warranty Service Center.

Motor will start automatically when tank

pressure drops below "cut-in" pressure

of pressure switch.

Remove and clean, or replace. DO NOT

OVER-TIGHTEN.

Check wiring connection inside pres-

sure switch and motor terminal box area.

1. Check fuse box for blown fuse and

replace if necessary. Reset circuit

breaker. Do not use a fuse or circuit

breaker with higher rating than that

specified for your particular branch

circuit.

2. Check for proper fuse; only Buss

"Fusetron"

Type T fuses are

acceptable.

3. Check for low voltage conditions.

4. Remove check valve and clean or

replace if it is stuck open or closed.

5. Disconnect any other electrical appli-

ances from circuit. The compressor

must operate on its own branch

circuit.

6. Do not use an extension cord.

Bleed

the line by pushing the lever on the

pressure switch to the OFF

position, opening the pressure

release valve. If the valve still

doesn't open, it must be replaced.

Have checked at an Authorized

Warranty Service Center. Do not

operate the compressor in the

spray area. See Flammable Vapor

Warning.